Enhancing Stability and Sustainability: The Role of Oil & Gas Well Casing

In the dynamic realm of oil and gas exploration, ensuring the stability and longevity of wells is paramount. One integral component that plays a pivotal role in achieving this is the Oil & Gas Well Casing. This article delves into the significance, functions, and materials used in constructing these essential components.

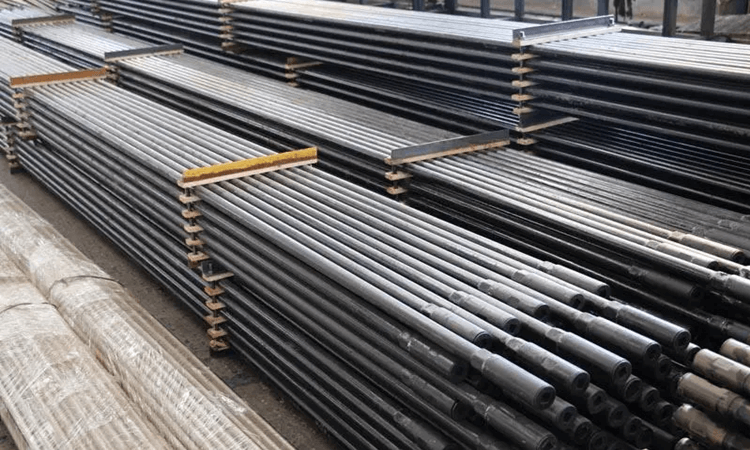

Oil & Gas Well Casing serves as a robust infrastructure designed to support and safeguard wells during drilling operations. Composed primarily of materials such as carbon steel or alloy steel, these casings are strategically installed layer by layer, extending from the wellhead to the reservoir depths.

Stabilizing Wellbore Integrity:

Oil & Gas Well Casing provides structural reinforcement to prevent wellbore instability. This is crucial in mitigating the risk of collapses or wall failure, thereby ensuring the overall stability of the well.

Preventing Contamination:

An imperative function of casing is to act as a barrier against the intrusion of undesired substances, such as groundwater or rock debris. This protective measure prevents contamination of the oil or gas within the well.

Formation Isolation:

Different geological formations often characterize subsurface environments. The casing isolates these formations, preventing interference between layers and ensuring the integrity of the extracted resources.

Enhancing Safety:

Oil & Gas Well Casing significantly contributes to the safety of well operations. By reducing the risk of accidents and maintaining a secure wellbore, these casings play a vital role in safeguarding both personnel and equipment.

Materials and Installation:

Commonly constructed from durable metals like carbon or alloy steel, Oil & Gas Well Casings are designed to withstand harsh downhole conditions. The installation process involves layering the casing into the drilled hole and injecting cement slurry into the annular space between the casing and the wellbore, solidifying the structure.

In conclusion, the installation of Oil & Gas Well Casing stands as a linchpin in the successful development and maintenance of oil and gas wells. By prioritizing stability, preventing contamination, and enhancing safety, these casings contribute significantly to the sustainability of the industry. As technology advances, the evolution of well casing materials and designs continues to refine and optimize this critical component, ensuring a robust foundation for the future of oil and gas exploration.