Drill pipe material selection

Drill pipe is an important tool used for oil drilling. Its material and strength requirements are very high to cope with complex underground environments and huge operating loads. Material selection is the first step in drill pipe manufacturing. Different materials have different physical and chemical properties, which directly affect key properties such as strength, wear resistance, corrosion resistance and high temperature resistance of drill pipes. The following are commonly used drill pipe materials and their impact on material selection and strength requirements.

First of all, the material of the drill pipe needs to have good mechanical properties and chemical stability to ensure that it can maintain strength and durability when used under harsh conditions underground. Generally speaking, commonly used drill pipe materials include carbon steel, alloy steel and stainless steel.

Carbon steel is one of the commonly used drill pipe materials with good processability, toughness and mechanical properties. Carbon steel has high strength and is suitable for most oil drilling operations, but it is prone to deformation and corrosion under high temperatures, high pressures or corrosive environments. Therefore, higher grade alloy steel or stainless steel is required under some special conditions.

Alloy steel is a material that improves the hardness, strength, wear resistance and corrosion resistance of steel by adding a certain proportion of alloy elements to the steel, thereby increasing the service life and wear resistance of the drill pipe. Common alloying elements include tungsten, nickel, molybdenum and titanium. Alloy steel has higher strength and corrosion resistance than carbon steel and can provide better performance in high temperatures and corrosive environments.

Stainless steel is a type of steel with high corrosion resistance, mainly composed of iron, chromium, nickel and other alloying elements. Stainless steel drill pipe has excellent corrosion resistance and can maintain good performance in high temperature, high pressure and corrosive environments. It is especially suitable for drilling operations in marine and acidic well environments. The corrosion resistance of stainless steel can reduce corrosion losses of drill pipes during work and improve the efficiency and economy of oil extraction.

Secondly, the strength requirements of drill pipes mainly include tensile strength, yield strength and impact toughness. Tensile strength refers to the stress that the rod material can withstand under tension, and Yield strength refers to the stress experienced by a rod material when it begins to undergo plastic deformation.Impact toughness refers to the rod's ability to resist rupture when subjected to impact loads.

In oil drilling operations, drill pipes need to withstand huge operating loads, such as rotational torque, push and pull forces, and the impact of rocks and well fluids on the drill pipe. Therefore, drill pipe materials need to have high tensile strength and yield strength to ensure that no fracture or plastic deformation occurs during operation.

In addition, the underground environment is often very complex, and sometimes encounters problems such as high temperature, high pressure, and corrosion. Therefore, drill pipe materials need to have good corrosion resistance and be able to be used for a long time in harsh environments without damage.

In addition to the above requirements, drill pipes also need to have certain fatigue resistance properties. During drill pipe operations, the drill pipe will be subjected to repeated cyclic loads and is prone to fatigue rupture. Therefore, drill pipe materials need to have high fatigue strength and fatigue life to ensure the reliability and safety of operations.

In general, the material and strength requirements of drill pipes are very high. During the material selection process, factors such as material performance, cost, and availability need to be considered. Only through comprehensive trade-offs can the appropriate material be selected to ensure the excellent performance and long-term stable operation of the drill pipe under various working conditions. Different regions and operating conditions may require drill pipes made of different materials, but whether it is carbon steel, alloy steel or stainless steel, they all need to have good mechanical properties, chemical stability, corrosion resistance and fatigue resistance to cope with complex underground conditions. environment and huge operating loads. Only by meeting these requirements can drill pipes play an efficient, safe and reliable drilling role.

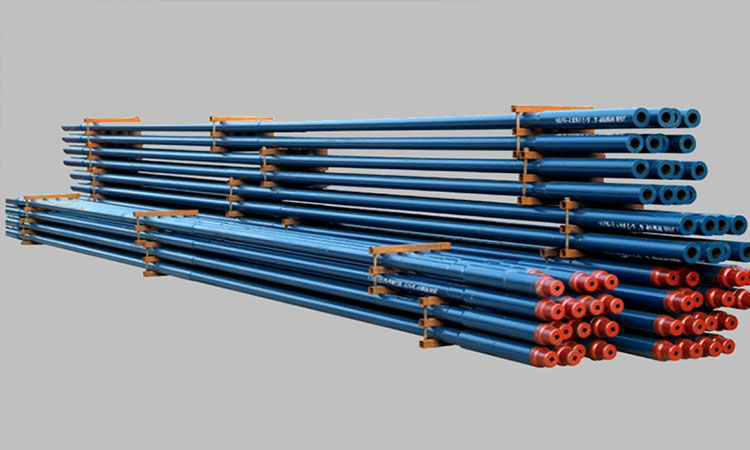

Supplier of drill pipes

Sino Mechanical Equipment provides various drilling tools,such as:drill pipes,Heavy Weight Drill Pipes,Square Kelly and Hexagonal Kellys,drill collars,drilling stabilizers,Tubing and casing,IBOP,hole openers,downhole motors,Milling Shoes and Milling tools,etc.It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.