Different Types of Pipe Sticking Issues and Solutions in Drilling

While modern drilling technology and equipment have made significant advancements, pipe sticking issues can still occur, especially in complex geological conditions or due to other instability factors. Pipe sticking problems can lead to project delays, increased costs, and safety risks. Therefore, drilling engineers and operators need to be prepared to address various types of pipe sticking problems and take preventive measures to reduce their frequency.

Today, Sino Mechanical is here to discuss different types of pipe sticking issues and their solutions during the drilling process, hoping to be of assistance to you.

Some of the most common pipe sticking issues encountered in daily operations and their solutions include:

1.Torque Stalling: Torque stalling occurs when the torque suddenly increases during the rotation of the drill pipe, preventing the drill bit from turning.

Solution: Reduce rotation speed, increase drilling fluid pump pressure, check for drill bit wear, change lubricants, or use spiral drill pipes to alleviate torque.

2.Vibration Sticking: Vibration sticking happens when vibrations cause the drill pipe or drill bit to get stuck in the wellbore during drilling.

Solution: Reduce vibration frequency, lower drilling speed, adjust downward pressure, replace the drill bit, improve wellbore design, or use vibration-damping tools to mitigate vibration issues.

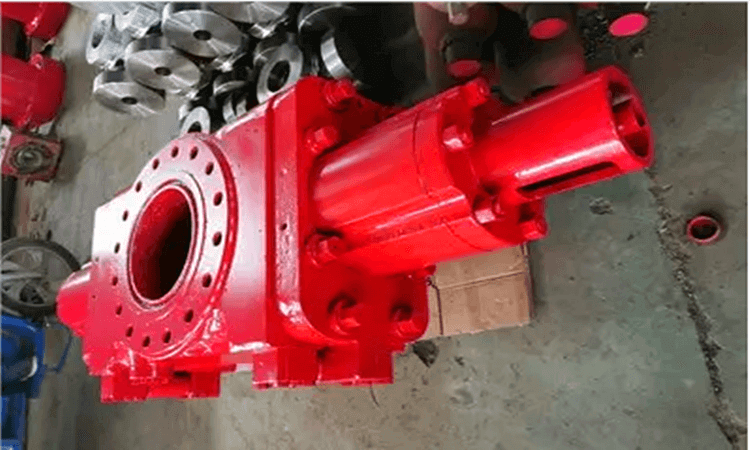

3.Differential Sticking: Differential sticking is caused by the pressure differential inside and outside the wellbore, leading to the drill pipe sticking to the wellbore wall.

Solution: Adjust drilling fluid properties, reduce pressure differential, use hollow drill tools, apply anti-sticking agents or lubricants to alleviate the effects of differential sticking.

4.Reactive Sticking: Reactive sticking occurs when the drill pipe or drill bit gets stuck due to friction with the wellbore wall.

Solution: Reduce downward pressure, improve drill pipe lubrication, decrease the outer diameter of the drill bit, adjust drilling fluid properties, use friction-reducing tools to mitigate reactive sticking.

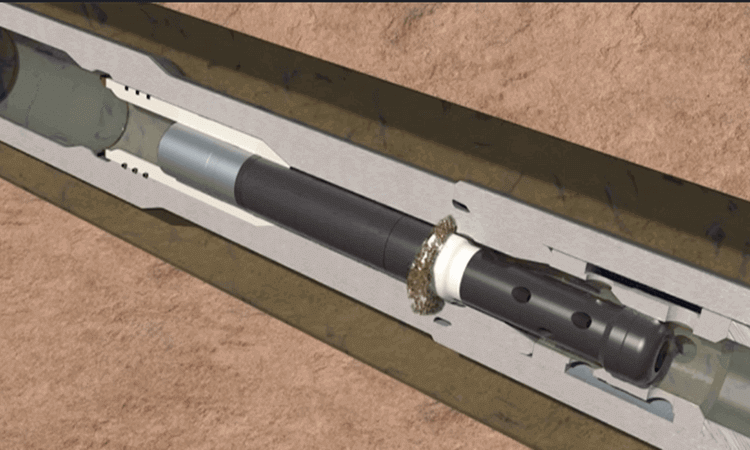

5.Lost Circulation Sticking: Lost circulation sticking arises when drilling fluid infiltrates the wellbore wall, causing a drop in wellbore pressure and potentially leading to pipe sticking.

Solution: Use lost circulation materials to seal off the lost circulation zone, adjust drilling fluid density, use packers, or employ boost pumps to maintain wellbore pressure and minimize lost circulation sticking.

6.Wellbore Geometry Sticking: Wellbore geometry sticking occurs due to changes in wellbore shape, leading to the drill pipe or drill bit getting stuck.

Solution: Improve wellbore design, adjust drilling parameters, reduce wellbore deviation, use guidance tools, and other means to mitigate sticking caused by wellbore shape changes.

In addition to pipe sticking issues, drilling operations may encounter problems like wellbore collapse, wellbore instability, and blowouts, among others. This requires drilling engineers and operators to select the right drilling tools and continually improve drilling techniques.

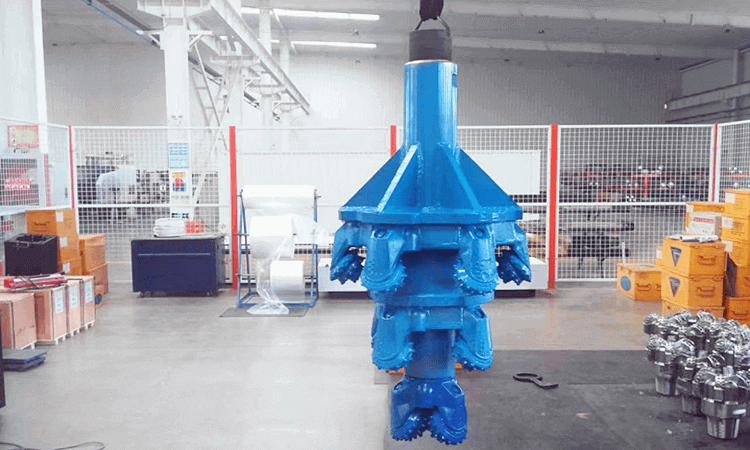

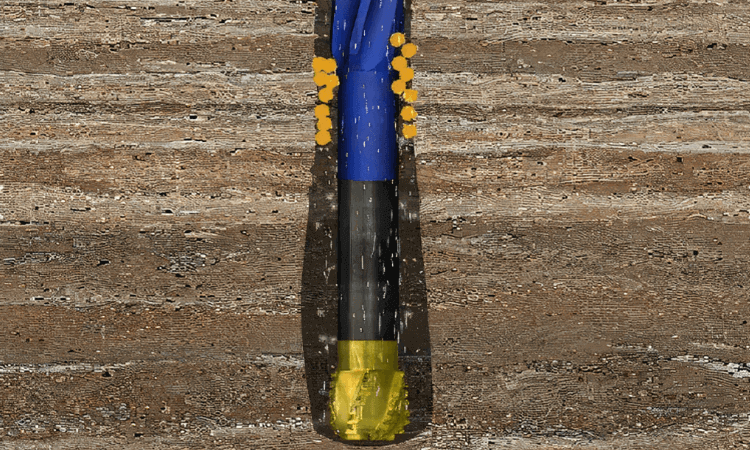

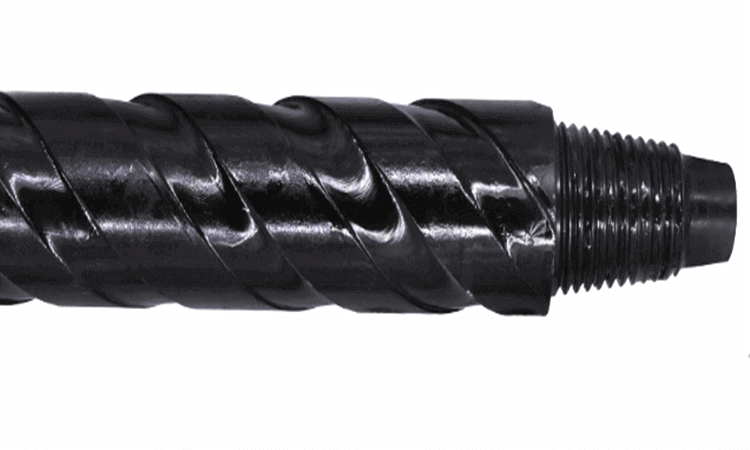

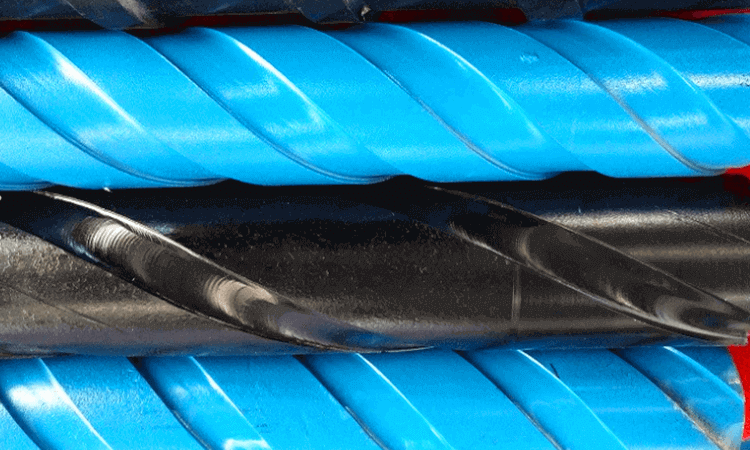

Sino Mechanical manufactures Heavy Weight Spiral Drill Pipes, which feature external spiral grooves to effectively reduce differential sticking and improve hole cleaning. Compared to standard drill pipes, Heavy Weight Spiral Drill Pipes offer several advantages:

Reduced torque requirements: The design of spiral drill pipes can lower torque demands, making it easier to address differential sticking as lower torque facilitates un-sticking operations.

Improved flushing effects: Spiral drill pipes typically offer better flushing effects as they allow drilling fluid to flow more freely around the drill pipe, aiding in debris removal and maintaining pressure balance.

Vibration reduction: Spiral drill pipes can often reduce vibrations during the drilling process, which helps decrease the risk of pipe sticking since vibrations can cause the drill bit to become stuck.

Therefore, Heavy Weight Spiral Drill Pipes can effectively reduce pipe sticking problems. However, the specific application should be carefully considered, and the best solution often needs to be determined based on the specific drilling conditions and requirements. If you have any requirements, feel free to contact us.