Differences in Working Principles and Applications between Annular and Ram BOPs

Blowout Preventers (BOPs) are vital safety equipment in the world of oil and gas drilling. They serve as the first line of defense in preventing and controlling well blowouts, which can be catastrophic if not managed properly. When it comes to BOPs, there are two primary categories that stand out – Annular and Ram BOPs. This article delves into the differences in their working principles and applications, shedding light on their respective strengths and areas of use.

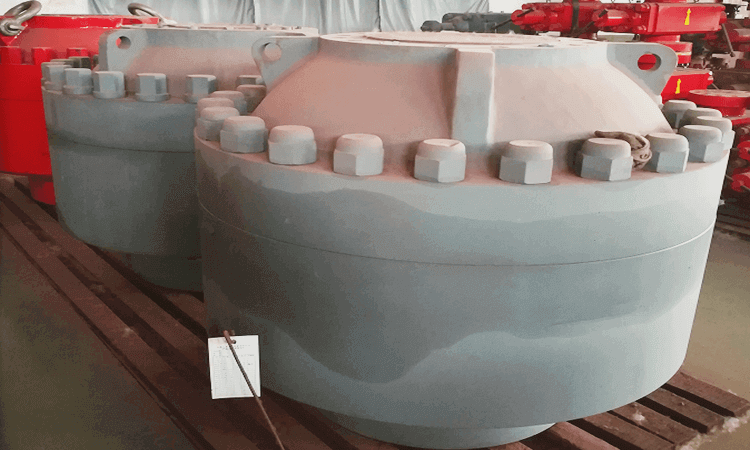

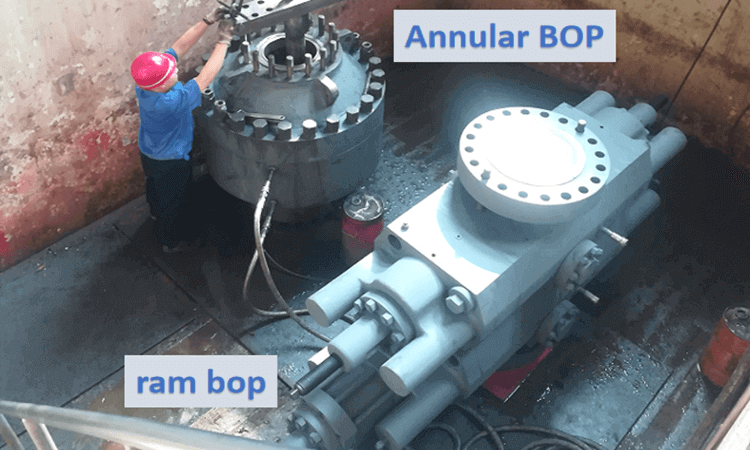

Annular BOPs

Annular BOPs design centers on creating a dynamic seal by utilizing a flexible rubber element that resembles a donut. These BOPs are suitable for a range of applications and are commonly used during drilling operations.

The working principle of an Annular BOP involves the rubber element being hydraulically pressurized, which causes it to expand and seal around the drill pipe or casing. This dynamic seal adapts well to different pipe sizes and irregularities, making it versatile and practical.

However, Annular BOPs may not provide the same level of pressure control as Ram BOPs in some situations. Engineers often emphasize pressure control when designing Ram BOPs, which are particularly well-suited for maintaining the integrity of the drill string.

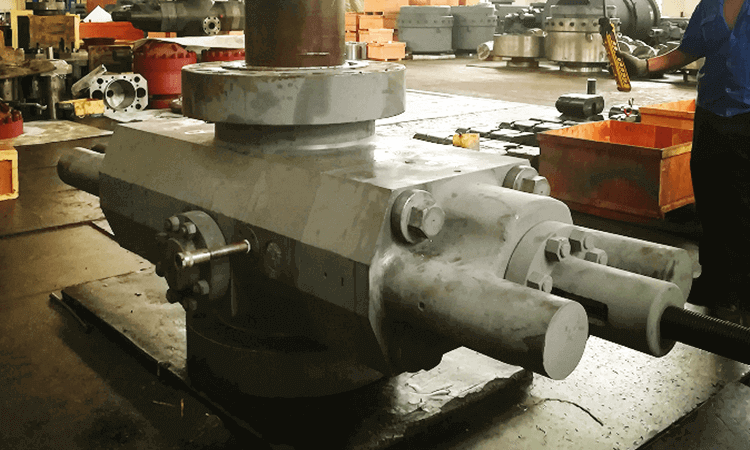

Ram BOPs

Ram BOPs, as the name suggests, employ a set of steel rams to seal off the wellbore. These rams, which come in various configurations, can shear through the drill pipe if necessary, effectively sealing the well. This design makes Ram BOPs an excellent choice for pressure control and containment.

Traditionally, Ram BOPs were relatively simple in their design, consisting of two halves that press together hydraulically. However, over the years, they have seen substantial improvements and redesign. Modern Ram BOPs often include features such as manual locking screws, hydraulic lock gaps, and large-bore shear valve covers. These enhancements ensure pressure control even in exceptional circumstances.

Applications

The choice between Annular and Ram BOPs largely depends on the specific requirements of the drilling operation. Annular BOPs are commonly used in drilling scenarios and are versatile enough to adapt to different pipe diameters. Their dynamic seal provides flexibility and ease of installation.

On the other hand, Ram BOPs are favored for their robust pressure control capabilities. They are particularly beneficial when the emphasis is on maintaining the integrity of the drill string and dealing with higher pressure and temperature conditions. Ram BOPs are also suitable for use in emergency situations due to their reliable sealing mechanisms.

Sino Mechanical, a trusted manufacturer in the industry, offers high-quality Ram BOPs. Our Ram BOPs are designed for durability and can withstand high pressures without leakage. This ensures that your wellhead remains completely sealed, allowing your oil drilling operations to proceed safely and efficiently.

In conclusion, both Annular and Ram BOPs play critical roles in well control and safety during drilling operations. Understanding their working principles and applications is essential for selecting the right BOP for the job, ensuring the protection of personnel and the environment in the oil and gas industry.