Decanter Centrifuge: Key Equipment for Efficient Solid-Liquid Separation

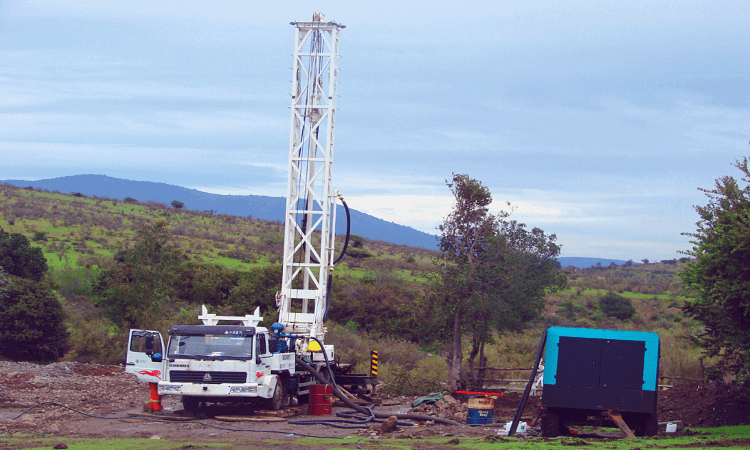

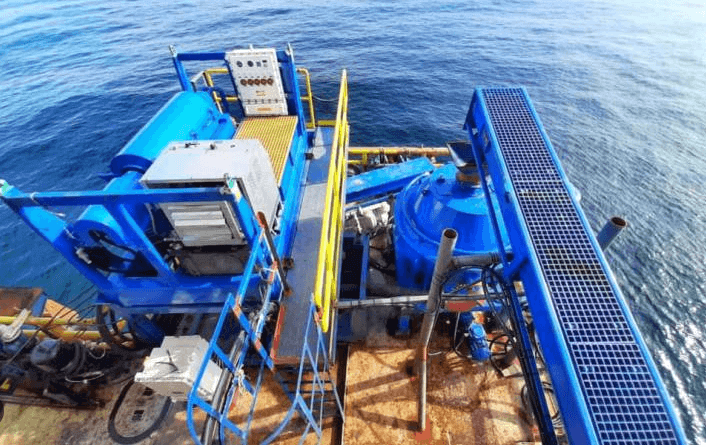

Decanting centrifuges are widely used in the drilling industry and play a crucial role in the solid-liquid separation process. This advanced equipment utilizes rotational and centrifugal forces to separate solid particles from the drilling fluid, providing a clean liquid phase for recycling or treatment while discharging solid waste. The application of decanter centrifuges has greatly improved the efficiency and sustainability of drilling operations.

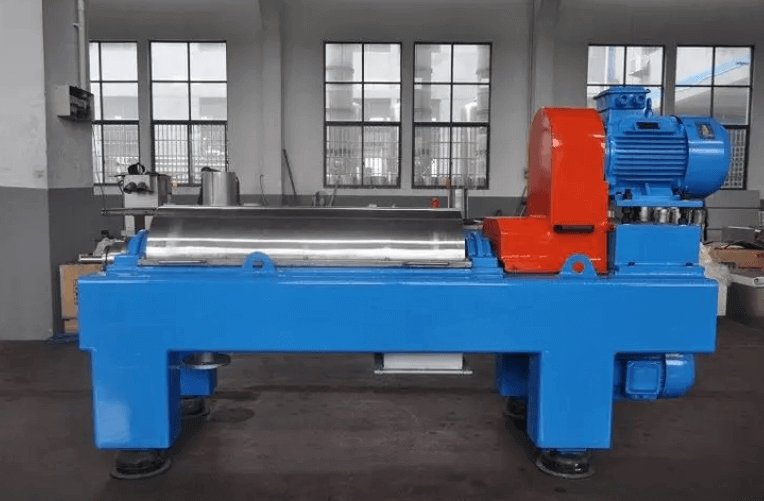

The main advantages of a decanter centrifuge are its excellent separation efficiency and processing capacity. It can effectively process a large amount of drilling fluid and quickly and accurately separate solid particles from the liquid phase. This efficient solid-liquid separation capability helps to improve the efficiency of drilling operations while reducing adverse environmental impacts.

In addition, the decanter centrifuge has flexibility and adaptability. It can be adjusted and optimized according to the characteristics of the drilling fluid to adapt to various working conditions and requirements. Whether dealing with high-density and high viscosity drilling fluids or low solid content in the liquid phase, the decanter centrifuge can provide excellent performance and stable operation.

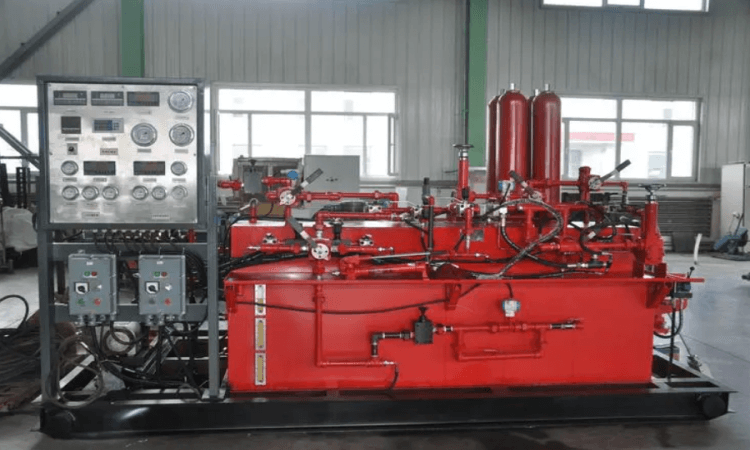

Safety is also an important feature of decanter centrifuges. Modern decanter centrifuges are equipped with advanced safety control systems and protective measures to ensure safe operation. These safety features include automatic shutdown devices, explosion-proof design, emergency stop buttons, etc., which effectively protect operators and equipment during operation.

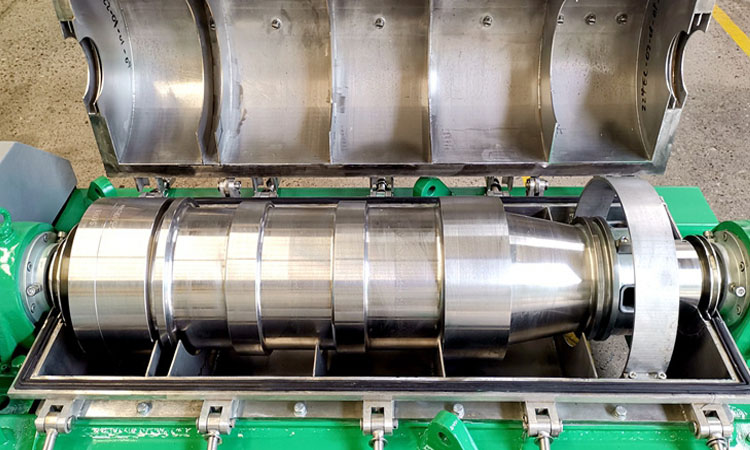

Significant progress has also been made in the technological innovation of decanter centrifuges. Manufacturers are constantly committed to developing new designs and technologies to improve the efficiency, reliability, and sustainability of centrifuge equipment. For example, the introduction of advanced automation control systems and intelligent technology has simplified and improved the accuracy of centrifuge operation. In addition, the application of energy-saving and environmental protection technology has optimized the power system, reduced energy consumption, and achieved sustainable drilling operations.

As a leading supplier in the drilling industry, Sino Mechanical is committed to the research and innovation of decanting centrifuges. We continuously optimize equipment design and performance to meet the needs of efficient solid-liquid separation. In addition, we provide comprehensive after-sales service and technical support to ensure the stable operation of the centrifuge and customer satisfaction.

In summary, the decanter centrifuge provides a reliable solution for efficient solid-liquid separation and plays a crucial role in the drilling industry. Its outstanding separation efficiency, flexibility, safety, and technological innovation make it an indispensable equipment in drilling operations. We will continue to innovate and provide customers with advanced, reliable, and sustainable decanting centrifuges, contributing to the development of the drilling industry.

If you need more information or have any other questions, please feel free to contact us at any time.