Composition and function of drill string

(I) Composition of drill string

Drill string is the general name of the steel pipe string above the drill bit and below the tap.

It includes square kelly, drill pipe, drill collar, various joints and stabilizers and other downhole tools.

(II) Function of drill string

(1) Provide a flow channel for drilling fluid;

(2) Provide drilling pressure to the drill bit;

(3) Transmit torque;

(4) Lift and lower the drill bit;

(5) Measure the well depth;

(6) Observe and understand the downhole conditions (drill bit working conditions, wellbore conditions, formation conditions);

(7) Perform other special operations (coring, cementing, salvage, etc.);

(8) Drill-Stem Testing, also known as mid-course testing.

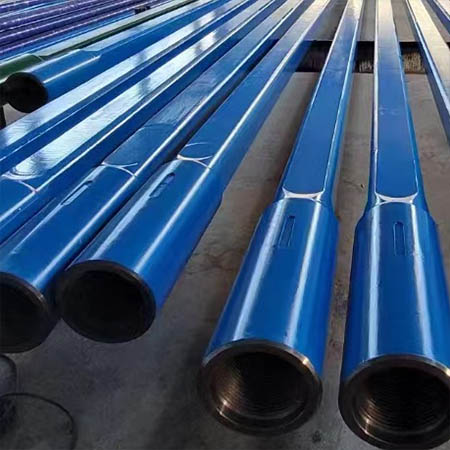

1. Drill pipe

(1) Function: Transmit torque and transport drilling fluid, and extend the drill string.

(2) Structure: pipe body + joint

(3) Specifications:

Wall thickness: 9 ~ 11mm, generally 9.19mm.

Outer diameter: Determined according to various drill pipe conditions, such as the commonly used 127, 140, etc.

Length: Generally around 9.5m.

(2) Joints and threads

Thread connection conditions: equal size, same thread type, matching male and female threads.

Drill pipe joint features: thicker wall, larger outer diameter, higher strength.

Drill pipe joint types:

Internal flat (IF), through-hole (FH), regular (REG); NC series

Internal flat type: mainly used for external thickened drill pipe. The characteristic is that the drill pipe has the same inner diameter throughout, and the drilling fluid flow resistance is small; but the outer diameter is larger and easy to wear.

Through-hole type: mainly used for internal thickened drill pipe. Its characteristic is that the drill pipe has two inner diameters, and the drilling fluid flow resistance is greater than the internal flat type, but its outer diameter is smaller than the internal flat type.

Regular type: mainly used for internal thickening drill pipe and drill bit, fishing tools. Its characteristics are that the inner diameter of the joint is less than the inner diameter of the thickening part and the inner diameter of the pipe body, the flow resistance of the drilling fluid is large, but the outer diameter is the smallest and the strength is large.

This type of joints all use V-type threads, but the buckle type, buckle distance, taper and size are very different.

NC series joints

NC23, NC26, NC31, NC35, NC38, NC40, NC44, NC46, NC50, NC56, NC61, NC70, NC77, etc.

NC—National Coarse Thread, (US) national standard coarse thread.

xx—indicates the pitch diameter of the base thread, the first two digits expressed in inches multiplied by 10.

For example: the pitch diameter represented by NC26 is 2.668 inches.

NC thread is also a V-thread. The several NC type joints listed in Table 2-17 have the same pitch diameter, taper, pitch and thread length as the old API standard joints and can be used interchangeably.

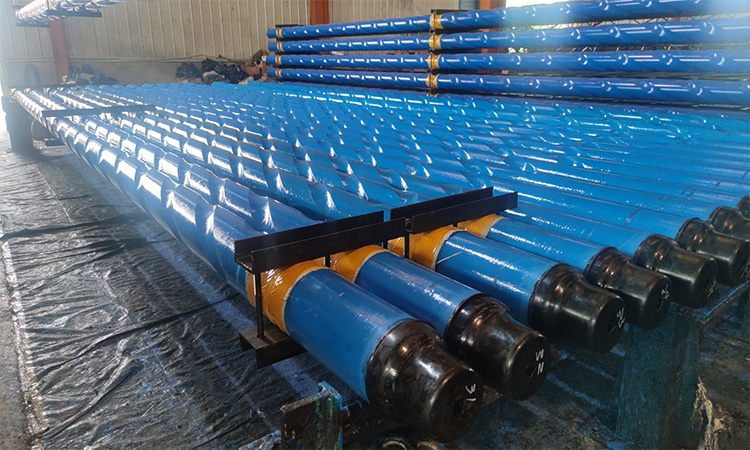

2. Drill collar

Structural features: Direct threading at both ends of the pipe body, no special joints; thick wall (38-53 mm), heavy weight and high rigidity.

Main functions:

(1) Apply drilling pressure to the drill bit;

(2) Ensure the necessary strength under compressive stress conditions;

(3) Reduce the vibration, swing and jump of the drill bit, so that the drill bit works smoothly;

(4) Control well inclination.

Type: smooth drill collar, spiral drill collar, flat drill collar.

Common sizes: 6-1/4〃, 7〃, 8〃, 9〃.

3. Square kelly

Type: square, hexagonal

Features: thick wall, high strength

Main functions: transmit torque and bear the full weight of the drill string.

Common sizes: 89mm (3.5 inches), 108mm (4.5 inches), 133.4mm (5.5 inches).

4. Stabilizer

Type: rigid stabilizer, non-rotating rubber sleeve stabilizer, roller stabilizer.

Function:

1) Anti-deflection;

2) Control wellbore trajectory.

The drill collar, drill bit and other drilling tools (stabilizer, shock absorber, jar, etc.) below the drill pipe section in the drill string are all included in the scope of the lower drilling tool assembly. However, the lower drilling tool assembly generally refers to a section of the drill string within 30-40m above the drill bit that has a direct impact on the working characteristics of the drill bit, or a section of the drill string with other drilling tools in addition to the drill collar.

The ideal lower drilling tools assembly should meet the following requirements:

(1) It can effectively control the full angle change rate and well inclination of the wellbore to ensure the quality of the wellbore.

(2) The drill bit has high working stability and can apply a large drilling pressure, which is conducive to improving the drilling speed.

(3) In order to ensure smooth tripping and reduce costs, the assembly should be simplified as much as possible under possible conditions. For the lower drilling tools assembly of the inclination section of a directional well, it should mainly meet the special requirements of wellbore trajectory control.