Common troubleshooting and maintenance techniques for workover rigs

Workover rigsplay a crucial role in the oil and gas industry, facilitating the maintenance and intervention operations of wells. However, like any mechanical system, workover rigs can encounter issues that require troubleshooting and maintenance. This article will explore some common troubleshooting techniques and maintenance tips for workover rigs.

1.Regular Inspection and Lubrication:To prevent potential failures and extend the lifespan of workover rigs, regular inspections and lubrication are essential. Inspect components such as drawworks, mud pumps, and hydraulic systems for signs of wear, leaks, or damage. Lubricate moving parts according to manufacturer guidelines to reduce friction and ensure smooth operation.

2.Addressing Hydraulic System Problems:Hydraulic system failures can disrupt the performance of workover rigs. If experiencing hydraulic issues, check for low fluid levels, leaks, or clogged filters. Ensure that hydraulic hoses are in good condition and not damaged or kinked. Regularly monitor hydraulic pressure and temperature to detect abnormalities that may indicate potential problems.

3.Electrical System Checks:Many workover rig components rely on electrical systems for operation. Regularly inspect electrical connections, cables, and wiring for signs of damage, corrosion, or loose connections. Test electrical components, such as motors and sensors, to ensure they are functioning correctly. Keep electrical enclosures clean and free from debris that may cause overheating.

4.Preventive Maintenance for Engines:Workover rigs often rely on engines for power. Perform regular maintenance on engines, including oil and filter changes, air filter cleaning or replacement, and spark plug inspections. Follow manufacturer guidelines for maintenance intervals and engine-specific requirements. Regularly monitor engine performance, including temperature and oil pressure, to identify any potential issues.

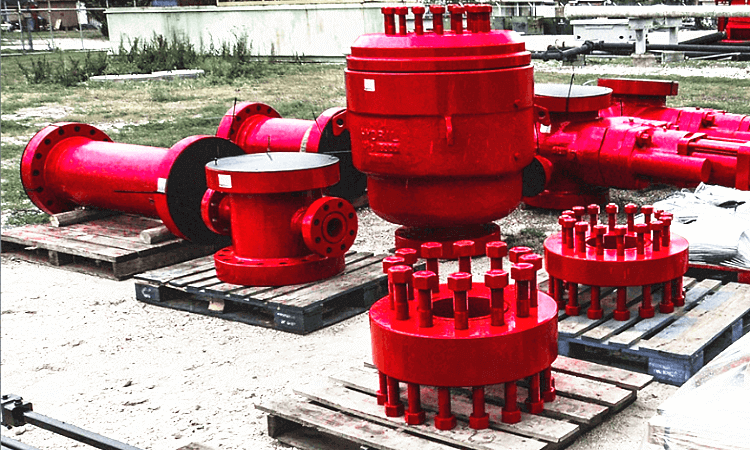

5.Proper Cleaning and Rust Prevention:Clean workover rigs regularly to remove dirt, debris, and contaminants that can impact performance and cause premature wear. After cleaning, apply appropriate protective coatings or rust inhibitors to prevent corrosion. Pay special attention to exposed components such as masts, pipes, and valves.

6.Training and Documentation:Ensure operators and maintenance personnel receive proper training on the specific workover rig being used. Knowledge of equipment operation, troubleshooting techniques, and routine maintenance procedures can help prevent potential failures and minimize downtime. Maintain detailed documentation of maintenance activities, including dates, performed tasks, and any issues or repairs encountered.

By implementing regular inspection, preventive maintenance, and troubleshooting techniques, operators can mitigate potential issues and ensure the reliable performance of workover rigs. Adhering to manufacturer guidelines, conducting thorough inspections, and addressing maintenance needs promptly can contribute to the longevity and efficiency of the equipment. Ultimately, a proactive approach to troubleshooting and maintenance enhances operational safety and minimizes downtime in the oil and gas industry.