Causes of Severe Wear in Drill Pipe Joints and Solutions

Drill pipe joints play a critical role in drilling operations, but they are often subjected to severe wear and tear. This article examines the reasons behind significant wear in drill pipe joints and proposes effective solutions to address this issue, enhancing the efficiency and safety of drilling operations.

Causes:

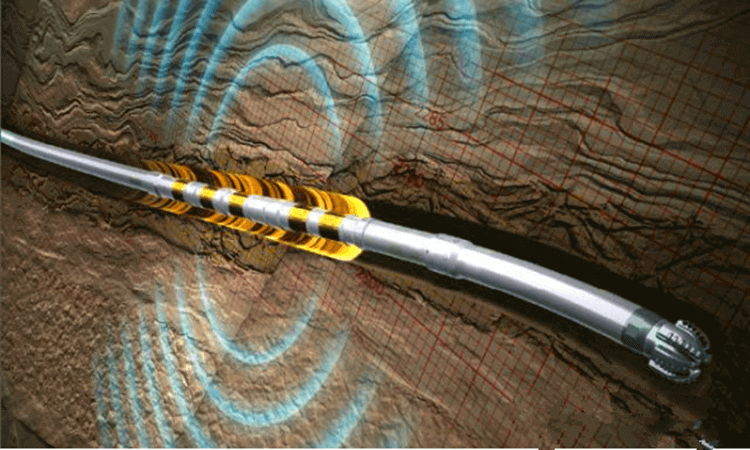

Hard Formation Drilling: When drilling through hard formations, drill pipe joints frequently encounter abrasive materials that cause substantial wear. The abrasive nature of these formations results in the rapid erosion of the pipe's surface.

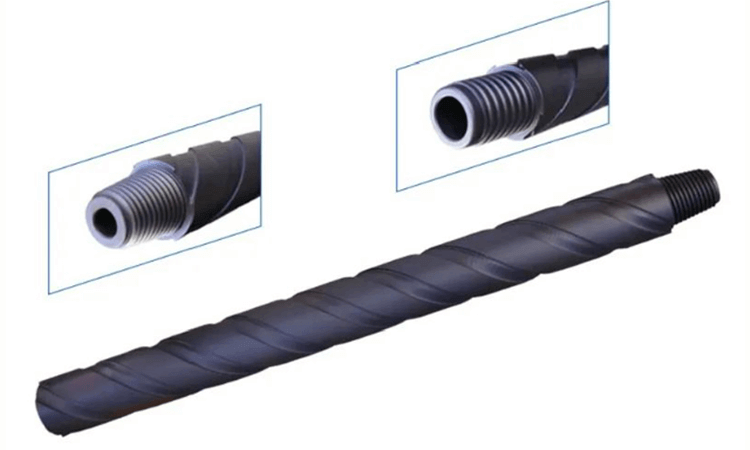

Characteristics of Wear: Severe wear in drill pipe joints is characterized by pronounced surface degradation, including pitting and grooving. This wear can compromise the structural integrity of the joints.

Friction and Vibration: Constant friction and vibration during drilling operations can lead to accelerated wear in the joints. The repetitive stress imposed by these factors gradually weakens the joint's material, making it more susceptible to wear-related issues.

Solutions:

Use of Abrasion-Resistant Coatings: Applying abrasion-resistant coatings to the outer surface of drill pipe joints is an effective way to mitigate wear. These coatings act as a protective barrier, reducing the impact of abrasive materials and extending the lifespan of the joint.

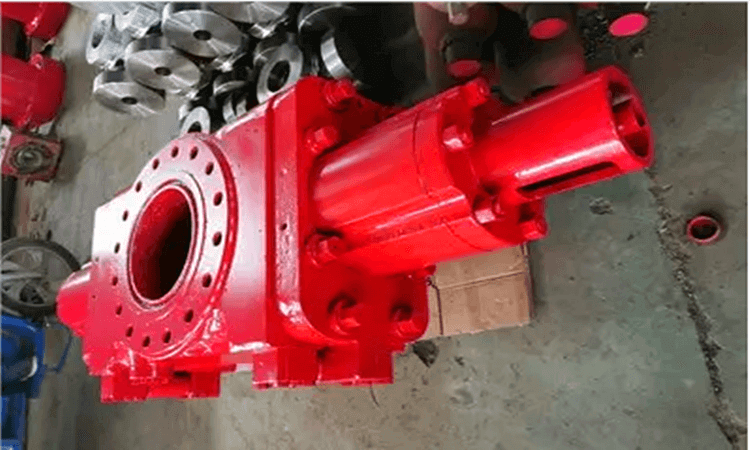

Regular Inspection and Maintenance: Implementing a rigorous inspection and maintenance schedule is crucial. Regularly inspecting drill pipe joints for signs of wear and promptly addressing any issues can prevent them from progressing to severe wear.

Proper Lubrication: Adequate lubrication between the drill pipe joints can significantly reduce friction and wear. Using high-quality lubricants helps maintain a smooth operation and minimizes the wear and tear caused by friction and vibration.

Material Selection: Choosing drill pipe joints made from high-quality, wear-resistant materials is essential. Material selection can significantly influence the joint's durability in challenging drilling conditions.

Severe wear in drill pipe joints can lead to operational inefficiencies and safety concerns. Understanding the causes, such as hard formation drilling, friction, and vibration, is the first step toward finding effective solutions. By implementing strategies like abrasion-resistant coatings, regular maintenance, proper lubrication, and careful material selection, the drilling industry can minimize the impact of wear and ensure the longevity and reliability of drill pipe joints. These measures not only enhance operational efficiency but also contribute to a safer and more sustainable drilling environment.

.png)