Causes and Solutions for Difficult Mud Pump Discharge

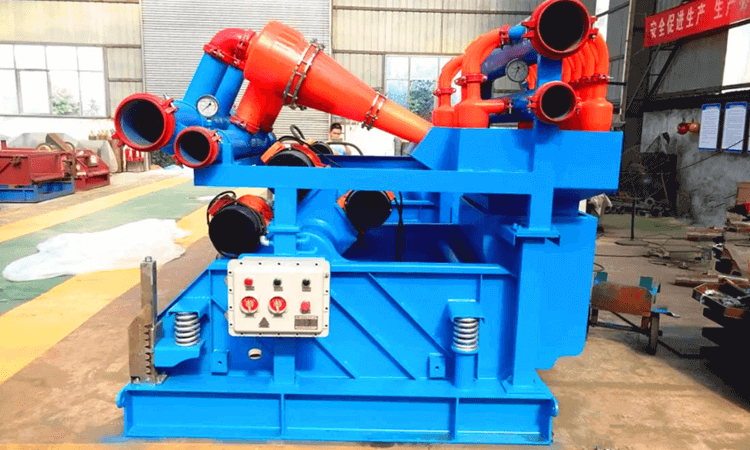

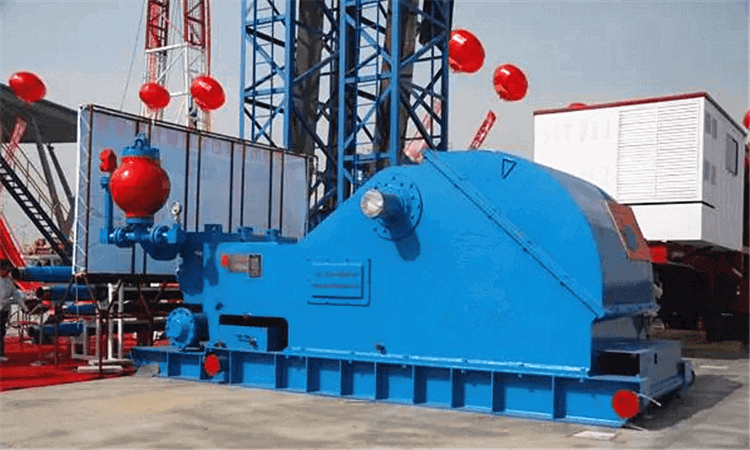

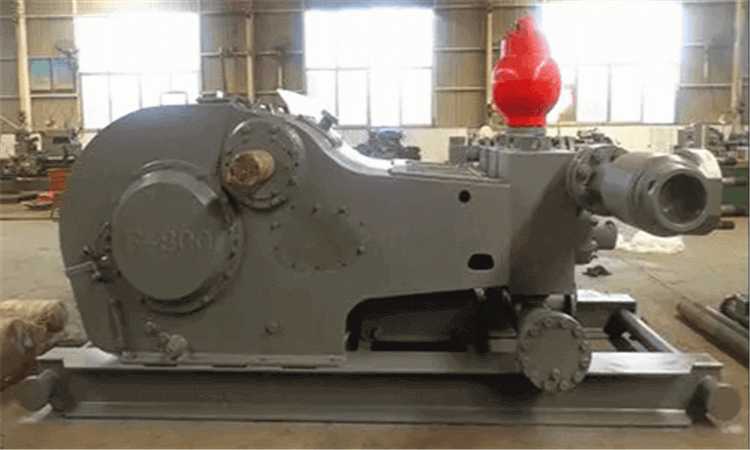

A mud pump is an essential piece of equipment in the process of oil drilling, playing a critical role in transferring mud from the surface to the wellbore. By generating high pressure, the mud pump propels mud to the wellhead and aids in removing drill cuttings and waste materials from the well, ensuring the smooth progress of drilling operations.

However, like any intricate mechanical device, mud pumps can face various challenges, including difficulties in mud discharge, leaks, and component wear. Addressing these issues requires drilling personnel to possess a certain level of mechanical and technical knowledge, allowing them to accurately identify problems and implement appropriate maintenance measures to ensure the safety and efficiency of drilling activities.

During drilling operations, mud pumps can encounter issues related to mud discharge, which can arise from a range of factors. The following are potential reasons and corresponding solutions:

1.Air Ingestion: If air enters the pump's intake pipeline, the pump may struggle to properly suction and discharge mud. This can be caused by loose connections, air leaks in the intake pipeline, or the formation of air bubbles due to agitation of the mud.

Solution: Inspect the pump's intake pipeline and connections to ensure proper sealing and prevent air from entering the pump. If air bubbles are present, try shutting down the mud pump and purging the air.

2.Mud Viscosity and Consistency: The viscosity and concentration of the mud can impact the pump's ability to discharge effectively. Overly thick mud can increase pump resistance, while overly thin mud might not generate enough pressure for proper discharge.

Solution: Adjust the mud formulation to maintain appropriate viscosity and concentration levels, enabling the pump to discharge mud effectively.

3.Faulty Check Valves: Damaged or clogged check valves within the mud pump can hinder proper operation.

Solution: Inspect and clean the check valves in the mud pump to ensure they open and close properly.

4.Damaged Pump Components: Components such as seals, pistons, and valves within the mud pump, if damaged or significantly worn, can lead to poor discharge.

Solution: Regularly inspect and maintain internal components of the mud pump to ensure they are in good working condition. If damage or wear is detected, promptly replace the affected components.

5.Drive Issues: Problems with the power source driving the pump (e.g., engine, motor) can result in difficulties with mud discharge.

Solution: Check whether the power source is functioning properly and has sufficient power to drive the pump.

6.Pump Blockages: Solid particles in the mud can cause blockages in the pump's intake and outlet, impeding proper discharge.

Solution: Regularly clean the pump's intake and outlet to prevent blockages. Adding appropriate chemical additives to the mud can help reduce the accumulation of solid particles.

When faced with difficulties in mud discharge, a systematic investigation should be conducted to identify the root cause of the issue. Subsequently, appropriate measures should be taken to resolve the problem. In all cases, adherence to safety protocols is crucial, and seeking professional assistance should be considered if needed.