Applications, Types, Advantages and Disadvantages of Screw Pump

The Screw pump transports liquid or semi-solid substances through the gap between the screw or spiral rotor and the shell. According to the different screw structures and working principles, Screw pump can be divided into single Screw pump, double Screw pump and three Screw pump.

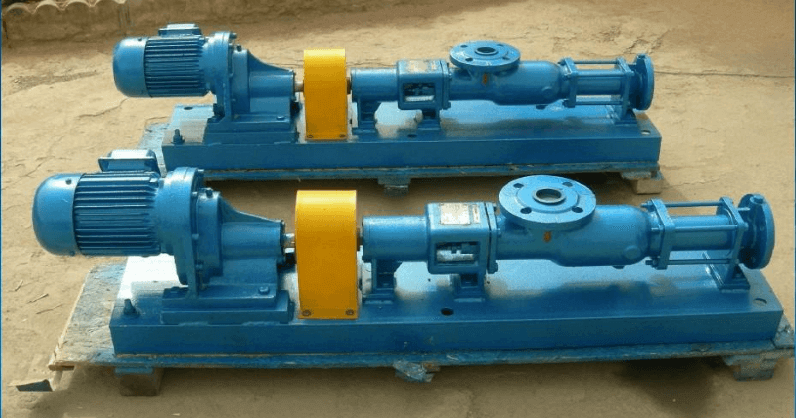

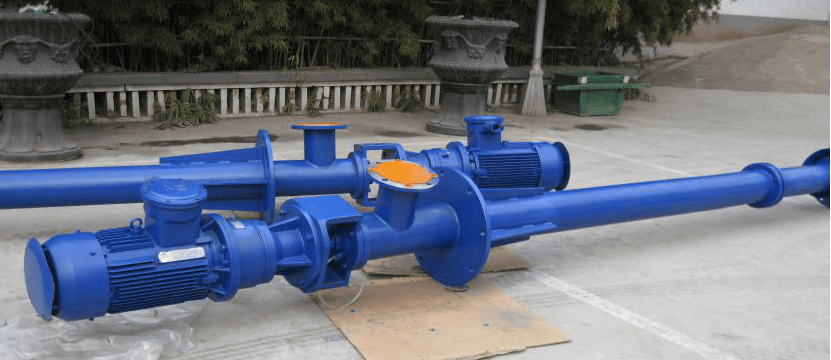

1.Single Screw pump: a single Screw pump consists of a screw rotor and a fixed housing. When the screw rotates, the liquid is sucked in and pushed along the axial direction of the screw, thus achieving transportation. Single Screw pump is suitable for low to medium viscosity liquid and semi-solid substances, commonly used in sewage treatment, food processing, petrochemical and other fields.

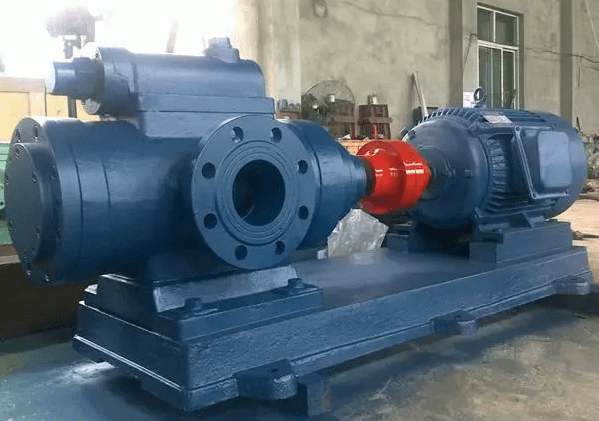

2.Twin Screw pump: twin Screw pump consists of two symmetrically rotating screw rotors and a shell. The gap between the screws forms a sealing chamber, and the liquid is sucked in and transported through the gap between the rotor threads. Twin screw pump has high pressure stability and conveying capacity, and is suitable for media with high viscosity, low flow rate and solid particles, which are commonly used in chemical, petroleum and marine industries.

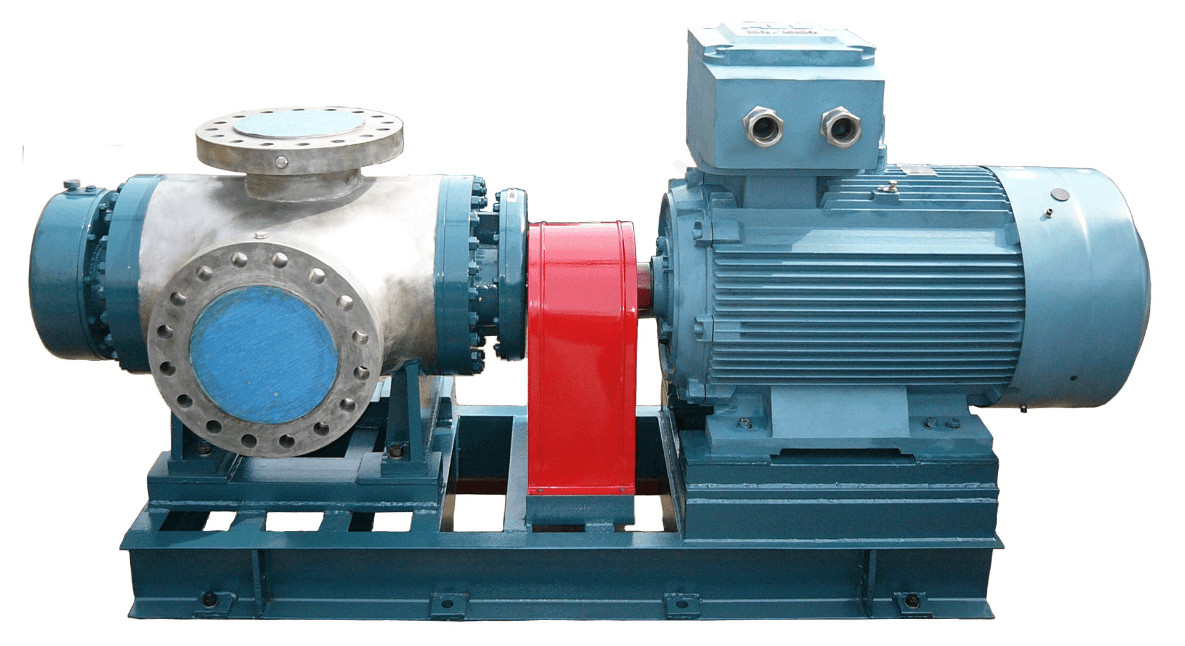

3.Three Screw pump: 3 Screw pump are composed of three screw rotors and a shell. Multiple sealing chambers are formed between the screws, through which liquid is sucked in and pushed forward. 3 Screw pump have higher pressure stability and transmission capacity, and are suitable for liquid media with high viscosity, high temperature and high pressure, which are commonly used in petroleum, chemical industry, power and other fields.

The advantages and disadvantages of Screw pump

Advantages:

Wide application: Screw pump is suitable for a variety of media, including high viscosity, semi-solid substances and liquids containing solid particles. They are widely used in various industries, including chemical, petroleum, food processing, sewage treatment, papermaking, power, etc.

Efficient energy utilization: Screw pump has efficient conveying efficiency and stable pressure characteristics, which can realize energy conservation.

Low pulsation: the continuous conveying characteristic of Screw pump makes the flow pulsation low, which is conducive to the stability of some technological processes.

Can transport high temperature medium: some types of Screw pump can handle high temperature liquid. Screw pump is a good method for extracting heavy oil and sand bearing crude oil. The Volumetric efficiency of Screw pump increases with the increase of crude oil viscosity.

Self suction capacity: Screw pump has better suction capacity, so it works better in long pipes, oil with higher viscosity and air in the fluid.

Disadvantages:

High initial investment: the initial investment cost of Screw pump is relatively high, especially for the Screw pump with large capacity and high performance.

High maintenance requirements: Screw pump requires high maintenance and cleaning requirements, especially when conveying solid particles or corrosive media, the screw and pump body need to be cleaned and maintained regularly.

Sensitivity to liquid: Screw pump is sensitive to the viscosity and characteristics of liquid, and the change of liquid may affect the performance and output of the pump.

Overall, Screw pump has been widely used in many industries and application fields due to its wide applicability, efficient energy utilization and low pulsation. Although the price of Screw pump is higher than other types of pumps, the characteristics of Screw pump are more obvious. For applications involving the transportation of fuel, oil and other lubricants, Screw pump and gear pump are usually selected as pumping technologies. Since the fluctuation of fluid thickness affects the performance of centrifugal pump much more than that of positive displacement pump, Screw pump and gear pump are usually the most effective solutions for oil and fuel. When choosing to use Screw pump, factors such as specific application demand, budget and medium characteristics should be comprehensively considered.

.jpg)

.jpg)