Application of Hose Loops in Primary Cementing Operations in Oilfield

Well cementing operations in oilfields are crucial steps in ensuring well safety and production stability. Throughout the cementing process, the use of various equipment and tools significantly influences operational efficiency and wellhead safety. Among these, "Hose Loops" play a vital role as key auxiliary equipment in primary well cementing operations in oilfields.

Overview of Hose Loops

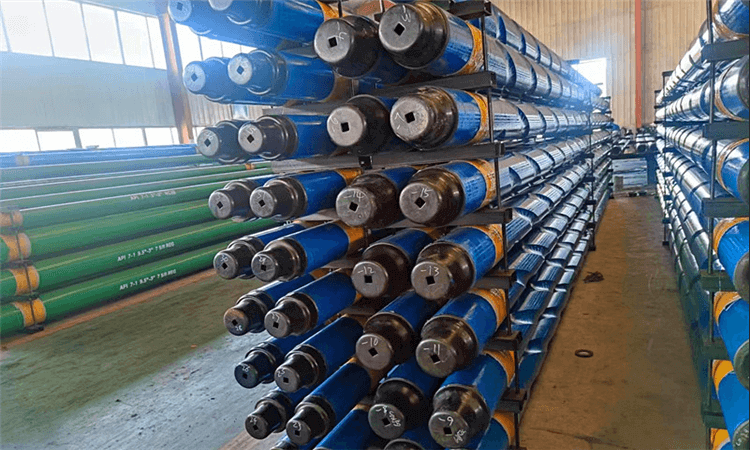

Hose Loops are flexible connecting devices, typically constructed from high-strength rubber and metal materials. Comprising multiple layers of pressure-resistant materials, they can withstand high-pressure and high-temperature environments while maintaining flexibility and durability. Hose Loops serve the primary function of connecting different equipment and pipelines in the wellhead area, facilitating the transfer of liquids, gases, and solid particles to target locations.

Applications of Hose Loops

In primary well cementing operations in oilfields, Hose Loops have a wide range of applications, including several key aspects:

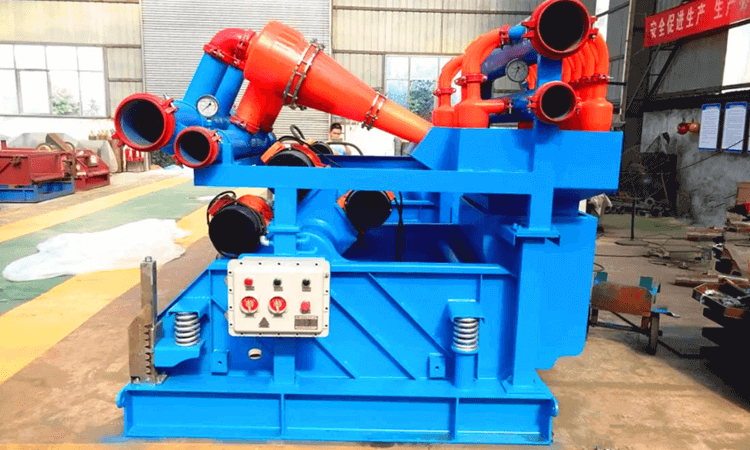

Mud Mixing and Conveying: During cementing operations, it's necessary to transport mud to the wellhead and mix it to achieve desired properties. Hose Loops connect mud tanks and mixing units, ensuring the stable conveyance and blending of mud to meet cementing requirements.

Fracturing Operations: Hydraulic fracturing involves injecting high-pressure fluids into wells to fracture reservoir formations and release energy. Hose Loops are used to convey fracturing fluids from pumping stations to the wellhead, ensuring efficient fluid injection.

Gas Venting and Monitoring: Potentially hazardous gases may be generated during cementing operations. Hose Loops are employed to guide gases from the wellhead to safe processing areas and can also be connected to gas monitoring devices to ensure the safety of personnel.

Material Conveyance: Various materials such as cement and steel balls may need to be transported during cementing operations. Hose Loops are used to convey these materials from storage areas to the wellhead, ensuring accurate placement of construction materials.

Advantages of Hose Loops

Hose Loops offer several advantages in primary well cementing operations:

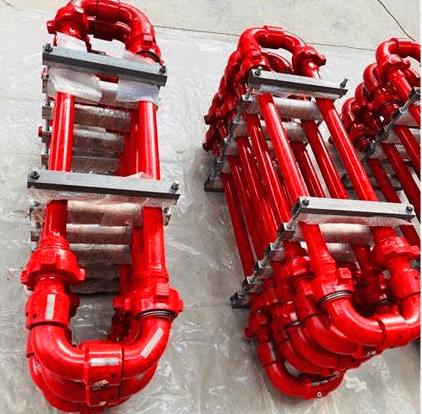

Flexibility: The flexible design of Hose Loops allows them to adapt to various angles and positions for connections, providing greater operational flexibility.

Pressure Resistance: Given that cementing operations involve high-pressure fluids, Hose Loops are designed to withstand high pressures, ensuring safe operations under high-pressure conditions.

Corrosion Resistance: Hose Loops are typically made from highly corrosion-resistant materials, allowing for prolonged use in harsh chemical environments.

Ease of Maintenance: The modular design of Hose Loops allows for the replacement of individual components, reducing downtime during maintenance.

In primary well cementing operations, Hose Loops are indispensable components for connecting and transferring fluids and materials between equipment. Their superior performance and multifunctionality make them a vital part of cementing operations, providing strong support for operational efficiency and wellhead safety.