Analysis of common faults in drilling mud pumps

Drilling mud pumps are critical components in the drilling process, used to circulate drilling fluids (mud) into the wellbore. Like any mechanical equipment, drilling mud pumps can experience various faults that may affect their performance and reliability. Here are some common faults that can occur in drilling mud pumps:

1.Cavitation: Cavitation occurs when the pressure inside the pump drops below the vapor pressure of the drilling fluid, causing the formation of vapor bubbles. These bubbles collapse when they enter regions of higher pressure, leading to shock waves and erosion of the pump components. Cavitation can result from high suction pressure, clogged or worn impeller, or improper pump settings.

2. Fluid leakage: Leakage of drilling fluid can occur at various points in the pump system, such as pump seals, valves, or piping connections. This can result in a loss of fluid circulation, reduced pump efficiency, and potential environmental hazards. Leaks can be caused by worn or damaged seals, improper installation, corrosion, or excessive pressure.

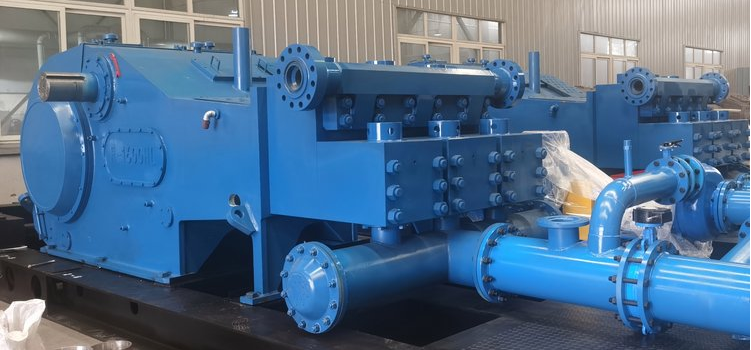

Sino Mechanical, as a Mud Pump manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Mud Pump.Our drilling mud pump has superior sealing performance, which can well solve the problem of fluid leakage.

3.Impeller wear: The impeller is a crucial component of the mud pump responsible for generating the fluid flow. Over time, the impeller can experience wear due to the abrasive nature of the drilling mud. This can lead to reduced pump performance, decreased flow rate, and increased power consumption. Regular inspection and maintenance can help identify impeller wear and prevent further damage.

4.Bearing failure: Bearings support the rotating shaft in the mud pump and enable smooth operation. Bearing failure can occur due to inadequate lubrication, excessive load, misalignment, or contamination. Failed bearings can cause pump vibration, increased noise, and eventual pump breakdown if not addressed promptly.

5.Shaft misalignment: Misalignment of the pump shaft can result in excessive stress on the bearings, leading to premature failure. Misalignment can occur due to improper installation, thermal expansion, or structural shifts. Regular alignment checks and adjustments are necessary to maintain the pump's performance and prevent mechanical issues.

6.Erosion and corrosion: Drilling mud often contains abrasive particles and corrosive chemicals. Over time, these can cause erosion and corrosion of pump components, such as the casing, impeller, and liners. This can result in reduced efficiency, loss of pump performance, and increased maintenance requirements. Using suitable materials and protective coatings can mitigate erosion and corrosion-related issues.

7. Vibration and noise: Excessive vibration and noise can indicate underlying problems in the mud pump, such as misalignment, unbalanced rotating parts, or worn components. Vibrations can lead to accelerated wear, decreased efficiency, and potential damage to surrounding equipment. Monitoring and addressing vibration and noise issues are crucial to maintaining the pump's reliability and preventing further failures.

Sino Mechanical manufactures and provides drilling mud pump in accord with API standard, as per international standards and your technical specifications requirements.Our mud pump has the advantages of Small size, simple structure, easy to carry.

To minimize these common faults and ensure the reliable operation of drilling mud pumps, regular inspection, preventive maintenance, and adherence to manufacturer's guidelines are essential. It's also important to train and educate operators and maintenance personnel to recognize early warning signs and take appropriate actions to address potential faults before they escalate into major failures.

Sino Mechanical manufactures and supplies high-performance, robust, and reliable Mud Pumps for land and offshore drilling applications.