All about metering pumps/controlled volume pumps

What is a metering pump?

Metering pump, also known as controlled volume pump or proportional pump, is a kind of pump that can meet the needs of various strict technological processes. The flow rate can be adjusted steplessly in the range of 0-100%.It is a special positive displacement pump for transporting various fluids, which belongs to the reciprocating pump. Metering pumps are often used in some applications that require precise delivery of liquids or delivery of several liquids in precise proportions as dosing pumps or chemical injection pump. Usually, the accuracy of metering pumps should not exceed ±1%.

Characteristics of metering pumps

The metering pump/controlled volume pump is a kind of fluid conveying machinery, and its outstanding feature is that it can maintain a constant flow regardless of the discharge pressure. The use of metering pumps can simultaneously complete the functions of delivery, metering and regulation, thereby simplifying the production process. Using multiple metering pumps, several media can be input into the process flow in accurate proportions for mixing. The main features of metering pumps of Sino Mechanical Equipment are as follows:

1. The metering pump has superior performance, among which the diaphragm metering pump has no leakage, high safety performance, accurate metering and delivery, the flow can be adjusted arbitrarily from zero to the maximum rated value, and the pressure can be arbitrarily selected from normal pressure to the maximum allowable range.

2. The adjustment is intuitive and clear, the work is stable, no noise, small size, light weight, easy maintenance, and can be used in parallel.

3.The pump has many varieties and complete performance, suitable for conveying from -30°C to 450°C, the maximum discharge pressure can reach 104Mpa, the flow range is 0.1-200000L/h, and the measurement accuracy is within ±1%.

4. According to the process requirements, the pump can be manually adjusted or frequency-converted to adjust the flow rate, and can also realize remote control and computer automatic control.

Classification of metering pumps

1. According to the overcurrent part

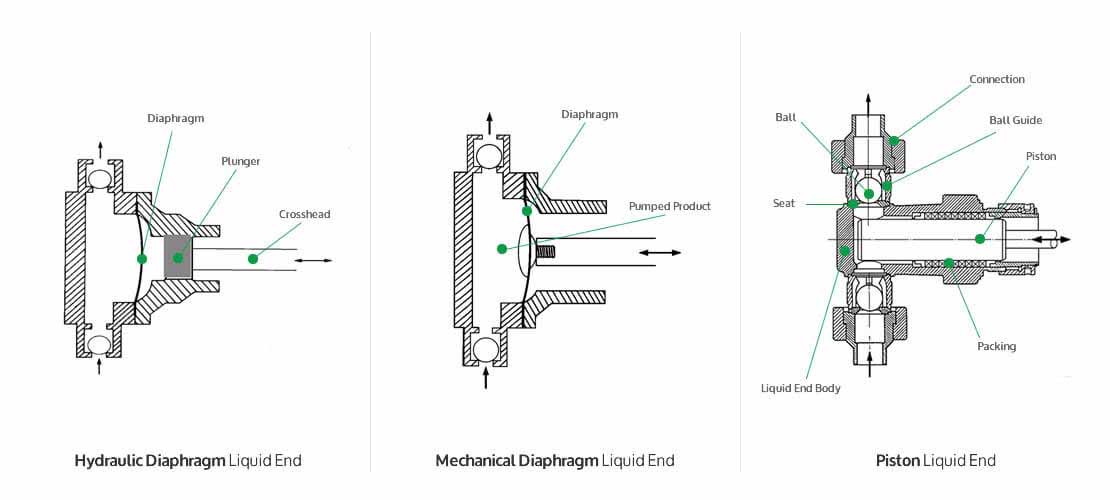

Plunger metering pumps

Piston metering pumps

Mechanical diaphragm metering pumps

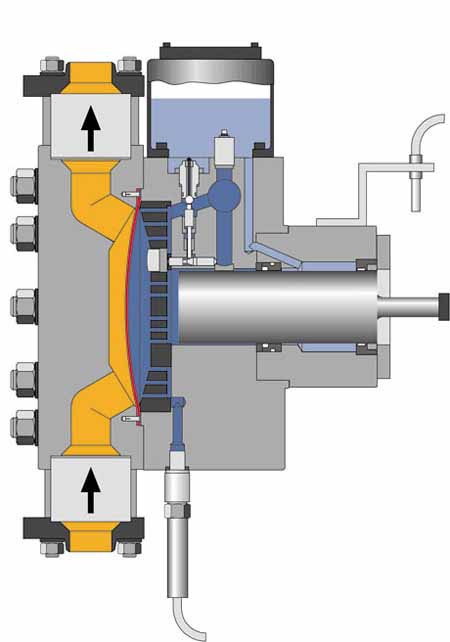

Hydraulic diaphragm metering pumps

2. According to the driving mode

Motor drive metering pumps

Electromagnetic drive metering pumps

Pneumatic drive metering pumps

3.Other classification methods: electric control type, air control type, heat preservation type, heating type, high viscosity type, etc.

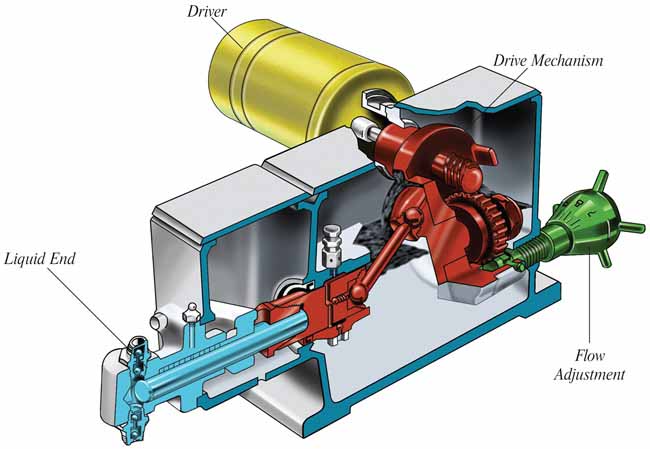

How a metering pump works

The metering pump is mainly composed of three parts: power drive, fluid delivery and regulation control. The power drive device drives the fluid delivery diaphragm (plunger) to reciprocate through the mechanical linkage system. The diaphragm (plunger) will be sucked by the delivery fluid in the first half of the stroke and discharged from the pump head in the second half of the stroke. The flow rate of the metering pump can be adjusted by adjusting the stroke frequency, stroke length, stroke frequency + stroke length, and adjusting the bypass. When adjusting the flow rate by adjusting the stroke length, it can be divided into three types: manual adjustment, electric adjustment and pneumatic adjustment.

Selection of metering pumps

1. Determine the pressure: The rated pressure of the selected metering pump should be slightly higher than the actual maximum pressure required, generally 10-20% higher. Do not choose too high, too high pressure will waste energy, increase equipment investment and operating costs.

2. Determine the flow rate: The flow rate of the selected metering pump should be equal to or slightly greater than the flow rate required by the process. The use range of the metering pump flow is better at 30% to 100% of the rated flow range of the metering pump. At this time, the repeatability of the metering pump is high. Considering the economy and practicality, it is recommended that the actual required flow rate of the metering pump be selected as 70-90% of the rated flow rate of the metering pump.

3. Determine the material of the pump head (fluid end): After the specific model and specification of the metering pump are determined, select the material of the flow part according to the properties of the flow medium. This step is very important. If the choice is improper, it will cause corrosion damage to the medium Wet parts or medium leakage pollutes the system, etc. In serious cases, it may cause major accidents.

4.Other aspects: When selecting a metering pump, it is also necessary to consider the accuracy level of the required metering pump. The higher the accuracy level, the greater the investment. The general working temperature of metering pump is -30~100℃, and the working temperature range of special metering pump is wider (for example, the delivery temperature of high temperature liquid metering pump with insulation jacket can reach 500℃). For the particle size of the medium, it is required to be less than 0.1mm. For the medium larger than 0.1mm, the flow structure of the pump can be changed to meet the needs. For the viscosity of the medium, it should generally be 0-1000cp, and the special metering pump can reach 10000cp.

5.Explosion-proof grade/protection grade requirements

Precautions for metering pumps

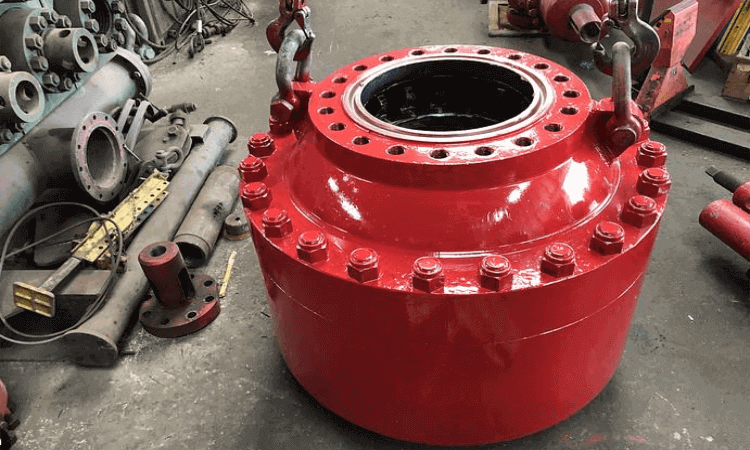

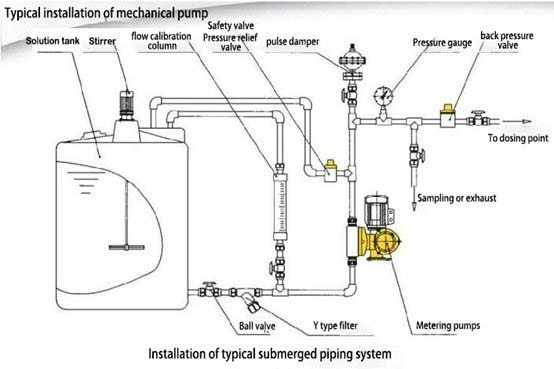

As a kind of reciprocating pump,the inlet and outlet of the pump should be installed with the following accessories:

Common accessories of the inlet pipeline: filter,calibration column

Common accessories of the outlet pipeline: safety valve and pulsation damper, back pressure valve if necessary.

Metering Pump Applications

Metering pump is a special reciprocating pump that can meet the needs of various strict technological processes. The flow rate can be adjusted steplessly within the range of 0-100%. It is used to transport liquids (especially corrosive liquids). As an ideal equipment for precision dosing of chemicals, it has been widely used in petrochemical, chemical, oil and gas fields, electric power, papermaking, pharmaceuticals, environmental protection, water treatment, etc.It is often used as dosing pumps or chemical injection pump.

Metering Pump Prices

Metering pumps include plunger metering pumps, mechanical diaphragm metering pumps, hydraulic diaphragm metering pumps, etc. The price will be affected by the type of the pump, raw materials, market environment, research and development costs, etc. Contact us to initiate an inquiry.

Supplier of metering pumps

Sino Mechanical Equipment is a supplier of high-quality metering pumps, providing plunger metering pumps, mechanical diaphragm metering pumps, hydraulic diaphragm metering pumps ,reciprocating pumps and related pulsation dampers/safety valves/calibration columns, etc