A Comprehensive Guide to Selecting Hydraulic Cylinders

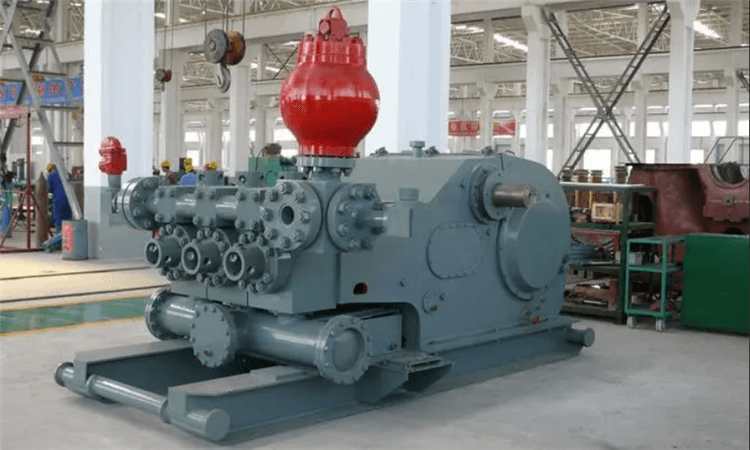

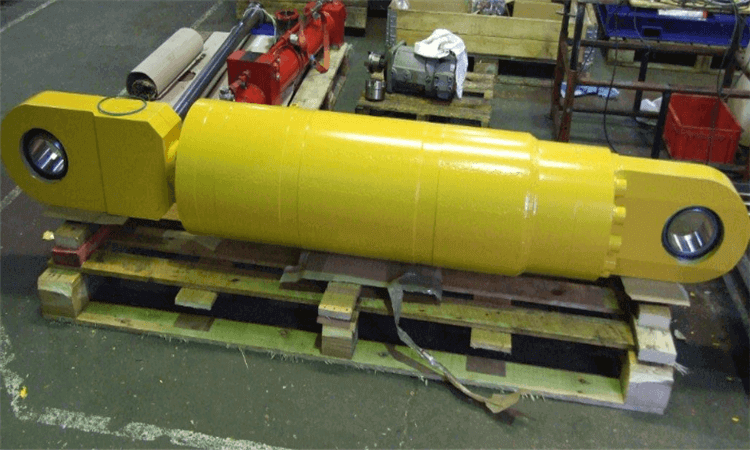

Hydraulic cylinders are commonly referred to as hydraulic rams. Hydraulic cylinders or hydraulic rams are widely used in engineering and industrial applications, converting hydraulic energy into mechanical motion and performing tasks such as lifting, pushing, compressing, and pulling. However, with a wide variety of hydraulic cylinders available, selecting the right one becomes a critical step in ensuring efficient and stable system operation. In this article, we will explore how to select hydraulic cylinders to assist readers in making informed decisions when faced with different requirements.

Determine Application Requirements:

Before selecting, it is essential to identify the specific application requirements of the hydraulic cylinder. This includes understanding its tasks, purposes, required load capacity, and stroke length, among other parameters. Different applications may demand various types and specifications of hydraulic cylinders, making clear application requirements the foundation of the selection process.

Load Capacity:

The load capacity of the hydraulic cylinder is a crucial consideration in the selection process. Ensure that the chosen hydraulic cylinder's load capacity meets the application requirements and leave a safety margin to avoid overload situations that could result in cylinder damage or unstable operation.

Stroke Length:

Select the appropriate stroke length based on the application's range of motion. The stroke length should fulfill the necessary linear motion requirements while avoiding unnecessarily long strokes that could lead to cost inefficiencies.

Working Pressure:

The working pressure of the hydraulic cylinder should match the maximum system pressure and operating environment. Choose a hydraulic cylinder suitable for the required working pressure to ensure stable and reliable performance.

Environmental Factors:

Consider the impact of the application environment on the hydraulic cylinder, such as temperature, humidity, and corrosiveness. Choose materials and seals suitable for specific environmental conditions to enhance the cylinder's durability and reliability.

Speed and Efficiency:

Speed and efficiency are also vital considerations in the selection process. For applications that require rapid motion, opt for hydraulic cylinders with higher speeds. For applications with high energy efficiency requirements, choose cylinders designed for improved efficiency to conserve energy consumption.

Quality and Reliability:

Select hydraulic cylinders from reputable suppliers to ensure product quality and reliability. High-quality hydraulic cylinders have advantages in terms of service life and performance, reducing failure rates and maintenance costs.

Installation and Maintenance:

Consider the installation and maintenance requirements of the hydraulic cylinder. Opt for cylinders that are easy to install and maintain, reducing maintenance costs and complexity.

In conclusion, selecting hydraulic cylinders is a process that requires comprehensive consideration of multiple factors. Clarifying application requirements is essential, and a comprehensive evaluation of load capacity, stroke length, working pressure, environmental factors, speed efficiency, quality, and reliability is necessary. Choosing the right hydraulic cylinder ensures efficient and stable system operation while meeting specific application needs. We recommend consulting with professional hydraulic system suppliers or engineers during the selection process to provide personalized hydraulic cylinder solutions and assist in making the best choices.