Description

Overview of Tubing and Casing

Oil Tubing and Casing are the lifeline to maintain the operation of oil wells. It is mainly used for the drilling of oil and gas wells and the transportation of oil and gas. The normal operation of the entire oil well. The tubing is a tube that is lowered into the casing of the well when the well is being produced normally. From the well, the oil flows through the oil pipe into the ground and enters the gathering process. In the coal mining well, the combination of oil pipe, sucker rod and deep well pump draws oil to the ground and enters the gathering process.

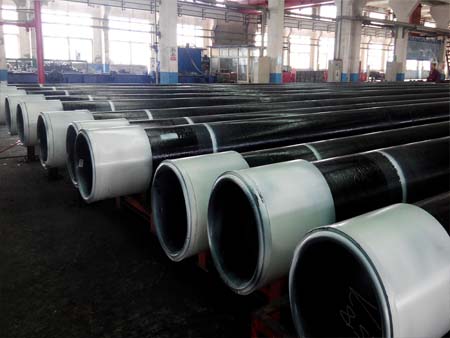

Casing is a series of steel pipes that are run into a drilled oil well to stabilize the well, keep contaminants and water out of the oil stream, and prevent oil from leaching into the groundwater. Casing is installed in layers, in sections of decreasing diameter that are joined together to form casing strings. The five types of casing string are conductor casing, surface casing, intermediate casing, casing liner, and production casing.

Oil Country Tubular Goods are popularly known as OCTG in the oil and gas industry. OCTG are pipe products which are used for the production of oil and gas. They are a wide range of steel tubular products which are used in the exploration, development and production, of oil and gas, particularly in the drilling process. They are useful both in the onshore or offshore production activities. OCTG pipe is manufactured or produced based on the standards set by API (American Petroleum Institute). Oil Country Tubular Goods include drill pipe, steel casing and tubing pipe, couplings, connections and accessories which are useful in oil production activities.

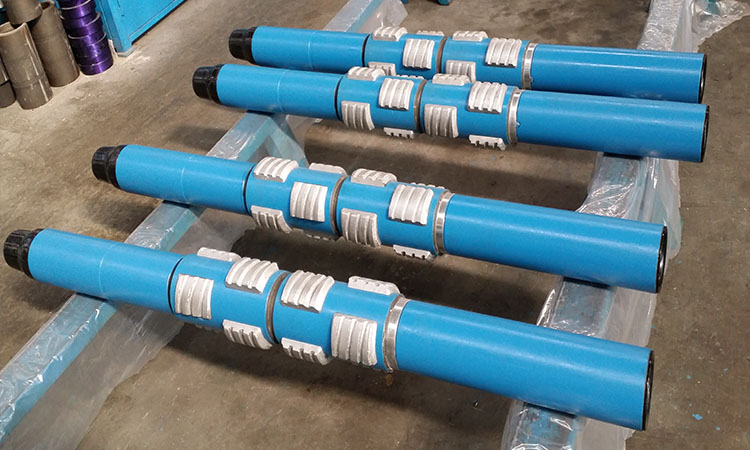

OCTG Tubing pipe goes inside the casing pipe because it is the pipe through which oil makes its way out. Tubing is the simplest part of OCTG and it is normally found in the segment of 30 ft (9 m), with threaded connections at both ends. The pipe is either used to transport natural gas or crude oil from the producing formation to the facilities where it will be processed after drilling is complete. This tubing must be able to withstand pressure during the extraction process and adequately resist loads and deformations that have to do with production and workovers. Just like casing is manufactured, tubing is also manufactured the same way, but an additional upsetting process is applied to make it thicker.

Casing is used for lining the complete borehole which has been dug into the ground to procure oil. Similar to the drill pipe, the oil well casing pipe is also subjected to axial tension, therefore they are required to be made from high-quality strong steel material. OCTG casing is large diameter pipe which are held in place in the borehole using cement.

The diameters of OCTG casing pipe range from 4.5″ to 36″. The well-cemented pipe acts as the structural component of the well and offer hole integrity. They prevent the well from collapsing when the drilling process is on. Good quality, well cemented casing can stay in place for the whole life of the well.

Casing is generally a steel pipe installed in wellbore and is cemented in place to prevent Wellbore collapse, cross flow of fluids between different reservoirs and to control abnormal formation pressures. Tubings are usually run inside casing (cased hole) and serves as a conduit through which oil and gas is produced. It is basically a tube inside casing which is used to produce reservoir fluids.

Reservoir casing, also known as production casing. It is the last layer of casing in the oil and gas well casing program, which goes down from the wellhead to below the oil and gas layer that passes through.

The depth at which the oil layer casing is run is basically the depth of the well.

The role of the oil layer casing is to channel the oil and gas to the ground, to isolate the oil and gas from all formations, and to ensure that the oil and gas pressure does not leak. After the oil layer casing is put into production, its quality must be guaranteed to maintain a certain production life.

On the one hand, the cementing quality of oil layer casing is related to the exploration well, which is the key to oil and gas testing; on the other hand, it is related to the production well, which directly affects the life of the well.

The cement plugging height of the gap between the oil layer casing and the well wall is at least 500 meters above the oil and gas layer, or 200 meters inside the upper layer of casing.

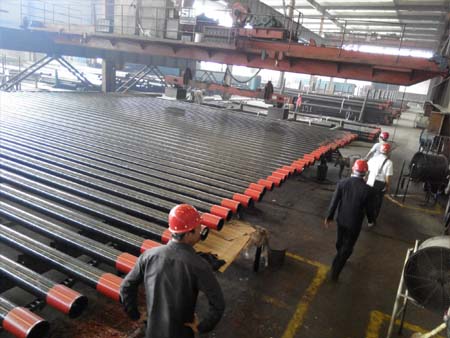

Petroleum casing is mainly used for oil and gas well drilling and oil and gas transportation. Due to different geological conditions, the downhole stress state is complex, and the tensile, compressive, bending and torsional stresses act on the pipe body comprehensively, which affects the casing itself. Quality puts forward higher requirements. Once the casing itself is damaged for some reason, it may lead to a reduction in production of the entire well, or even scrap it.

Tubing and casing are essential pipes in oil extraction.

The oil pipe is the pipe that is lowered into the casing of the oil well during normal production of the oil well. In the self-flowing well, the oil flow flows into the ground through the tubing and enters the gathering and transportation process. In mechanical production wells, oil pipes, sucker rods, and deep well pumps (that is, "three pumping" equipment) are combined to pump oil to the surface and enter the gathering and transportation process.

The casing is the pipe that is lowered into the well after the drilling is completed. The casing and the well wall are sealed with cement, and then the perforating gun is aimed at the target layer to perforate, so that the oil flows through the rock formation, the cement sheath, and the casing into the well. bottom, and then into the tubing to the ground.

After the oil well is drilled, the casing is run in, the casing and the well wall are sealed with cement, and the oil pipe is run in the casing. There are downhole tools such as oil packer and pump on the tubing, and the sucker rod is lowered into the tubing, and the sucker rod pulls the piston of the pump to reciprocate up and down. In this way, the oil is pumped to the surface.

Features of Tubing and Casing

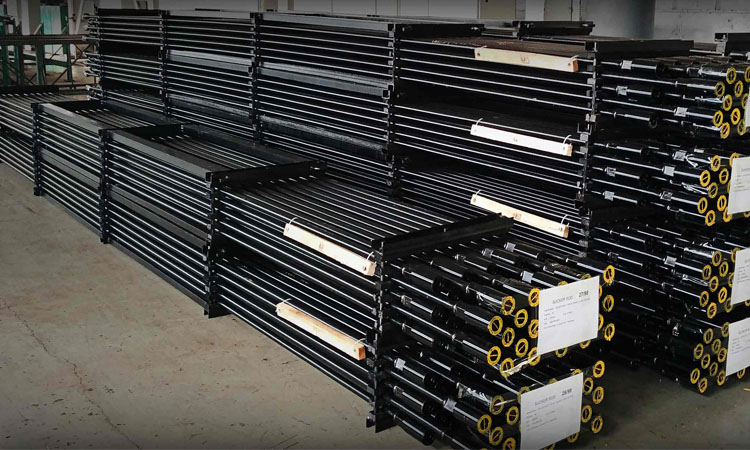

1. The length of the casing is not fixed, and its range is 8-13m. But casing not shorter than 6m can be provided, and its quantity shall not exceed 20%.

2. The inner and outer surfaces of the tubing and casing shall not have folds, hairlines, delaminations, cracks, folds and scars. These defects shall be completely removed, and the removal depth shall not exceed 12.5% of the nominal wall thickness.

3. The outer surface of the coupling of tubing and casing must not have defects such as folds, hairlines, separation layers, cracks, rolling folds, and scarring.

4. The thread surface of the tubing and casing and coupling should be smooth, without burrs, tears and other defects that can interrupt the thread and affect the strength and tight connection.

Applications of Tubing and Casing

Used in oil well drilling, tubing and casing are mainly used to support the well wall during the drilling process and after the well completion, so as to ensure the drilling process and the normal operation of the entire oil well after the well completion. Oil tubing and casing is a large-diameter pipe that fixes the walls or holes of oil and natural gas wells. The tubing and casing are inserted into the wellbore and fixed with cement to help the wellbore separate the rock formation and prevent the wellbore from collapsing, while ensuring the circulation of the drilling mud to facilitate drilling and production.

1. Reinforce the well wall to prevent formation collapse.

2. Isolate different oil layers and water layers to realize layered mining.

3. Tubing and Casing are convenient to implement measures such as fracturing and acidification and maintenance operations.

5. Form an oil flow channel to cooperate with the oil pipe to achieve the purpose of oil recovery.

Casing Classification

1. Surface oil casing: protect the drilling well from being polluted by shallow water layer and shallow gas layer, support wellhead equipment and maintain the weight of other layers of casing.

2. Technical oil casing: Separate the pressure of different layers so that the drilling fluid can flow normally and protect the production casing, and install anti-burst devices, leak-proof devices and tail pipes in the drilling.

3. Reservoir Oil Casing: Lead oil and natural gas out of the reservoir below the surface. Used to protect drilling wells and stratify drilling mud. When the oil casing is produced, the outer diameter is usually 114.3mm to 508mm.

What are the differences between casing and tubing?

Tubing are pipes through which the oil or gas is transported from the wellbore. Tubing segments are generally around 30 ft (9 m) long with a threaded connection on each end. Tubing comply with Specifications on Casing and Tubing (API Spec 5CT), Specifications on Processing, Measuring and Inspecting Casing, Tubing and Threads (API Spec 5B) and other related standards.

Casing pipe is a special tubular product for oil (gas or water) extraction. Casing pipe is particularly exposed to axial tension and internal pressure by the pumped oil or gas emulsion. Casing pipes comply with Specifications on Casing and Tubing (API Spec 5CT), Specifications on Processing, Measuring and Inspecting Casing, Tubing and Threads (API Spec 5B) and other related standards.

Price of Tubing and Casing

The Tubing and Casing Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Tubing and Casing. If you are looking for Tubing and Casing or Tubing and Casing spares, please kindly contact us to get the latest Tubing and Casing price.

Tubing and Casing Supplier

Sino Mechanical, as a Tubing and Casing manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Tubing and Casing. We are global Tubing and Casing supplier. We offer a wide range of drilling equipment and have Tubing and Casing for sale. We also provide OEM services. We design, manufacture, and sell Tubing and Casing for your drilling applications. If you want to know latest Tubing and Casing price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Tubing and Casing

| Tubing Size | Nominal Weight lb/ft | Outside Diameter | Wall Thickness | Type of End Finish | ||||||||

| Grade | ||||||||||||

Non -upset | External -upset | in | mm | in | mm | J55 | L80-1 | N80 | C90 | T95 | P110 | |

| 1.900" | 2.40 | - | 1.900 | 48.26 | 0.125 | 3.18 | PI | - | - | - | - | - |

| 2.75 | 2.90 | 1.900 | 48.26 | 0.145 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | - | |

| 3.65 | - | 1.900 | 48.26 | 0.200 | 5.08 | PU | PU | PU | PU | PU | PU | |

| 2 3/8" | 4.00 | - | 2.375 | 60.32 | 0.167 | 4.24 | PN | PN | PN | PN | PN | - |

| 4.00 | 4.70 | 2.375 | 60.32 | 0.190 | 4.83 | PNU | PNU | PNU | PNU | PNU | - | |

| 5.80 | 5.95 | 2.375 | 60.32 | 0.254 | 6.45 | - | PNU | PNU | PNU | PNU | PNU | |

| 6.60 | - | 2.375 | 60.32 | 0.259 | 7.49 | - | - | P | P | P | PNU | |

| 7.35 | 7.45 | 2.375 | 60.32 | 0.336 | 8.53 | - | PU | - | PU | PU | - | |

| 2 7/8" | 6.40 | 6.50 | 2.875 | 73.02 | 0.217 | 5.51 | PNU | PNU | PNU | PNU | PNU | - |

| 7.80 | 7.90 | 2.875 | 73.02 | 0.276 | 7.01 | - | PNU | PNU | PNU | PNU | PNU | |

| 8.60 | 8.70 | 2.875 | 73.02 | 0.308 | 7.82 | - | PNU | PNU | PNU | PNU | PNU | |

| 9.35 | 9.45 | 2.875 | 73.02 | 0.340 | 8.64 | - | PU | - | PU | PU | PNU | |

| 10.50 | - | 2.875 | 73.02 | 0.392 | 9.96 | - | P | - | P | P | - | |

| 11.50 | - | 2.875 | 73.02 | 0.440 | 11.18 | - | P | - | P | P | - | |

| 3 1/2" | 7.70 | - | 3.500 | 88.90 | 0.216 | 5.49 | PN | PN | PN | PN | PN | - |

| 9.20 | 9.30 | 3.500 | 88.90 | 0.254 | 6.54 | PNU | PNU | PNU | PNU | PNU | - | |

| 10.20 | - | 3.500 | 88.90 | 0.289 | 7.34 | PN | PN | PN | PN | PN | PNU | |

| 12.70 | 12.95 | 3.500 | 88.90 | 0.375 | 9.52 | - | PNU | PNU | PNU | PNU | - | |

| 14.30 | - | 3.500 | 88.90 | 0.430 | 10.92 | - | P | - | P | P | PNU | |

| 15.50 | - | 3.500 | 88.90 | 0.476 | 12.00 | - | P | - | P | P | - | |

| 17.00 | - | 3.500 | 88.90 | 0.530 | 13.46 | - | P | - | P | P | - | |

| 4" | 9.50 | - | 4.000 | 101.60 | 0.226 | 5.74 | PN | PN | PN | PN | PN | - |

| 10.70 | - | 4.000 | 101.60 | 0.262 | 6.65 | PU | PU | PU | PU | PU | - | |

| 4 1/2" | 12.60 | 12.75 | 4.500 | 114.30 | 0.271 | 6.88 | PNU | PNU | PNU | PNU | PNU | - |

| 15.20 | - | 4.500 | 114.30 | 0.380 | 8.56 | - | P | - | P | P | - | |

| 17.00 | - | 4.500 | 114.30 | 0.380 | 9.65 | - | P | - | P | P | - | |

| 18.90 | - | 4.500 | 114.30 | 0.430 | 10.92 | - | P | - | P | P | - | |

| 21.50 | - | 4.500 | 114.30 | 0.500 | 12.70 | - | P | - | P | P | - | |

| 23.70 | - | 4.500 | 114.30 | 0.560 | 14.22 | - | P | - | P | P | - | |

| 26.10 | - | 4.500 | 114.30 | 0.630 | 16.00 | - | P | - | P | P | - | |

| Casing Size | NominalWeight lb/ft | Outside Diameter | Wall Thickness | Type of End Finish | |||||||||

| Grade | |||||||||||||

| in | mm | in | mm | J55 K55 | L80-1 | N80 | C90 | C95 | T95 | P110 | M65 | ||

| 4 1/2" | 9.50 | 4.500 | 114.30 | 0.205 | 5.21 | PS | - | - | - | - | - | - | - |

| 10.50 | 4.500 | 114.30 | 0.224 | 5.69 | PSB | - | - | - | - | - | - | - | |

| 11.60 | 4.500 | 114.30 | 0.250 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 13.50 | 4.500 | 114.30 | 0.290 | 7.37 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 15.10 | 4.500 | 114.30 | 0.337 | 8.56 | - | - | - | - | - | - | PLB | - | |

| 5" | 11.50 | 5.000 | 127.00 | 0.220 | 5.59 | PS | - | - | - | - | - | - | - |

| 13.00 | 5.000 | 127.00 | 0.253 | 7.52 | PSLB | - | - | - | - | - | - | - | |

| 15.00 | 5.000 | 127.00 | 0.296 | 9.19 | PSLB | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 18.00 | 5.000 | 127.00 | 0.362 | 9.19 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 21.40 | 5.000 | 127.00 | 0.437 | 11.10 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 5.000 | 127.00 | 0.478 | 12.14 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 5.000 | 127.00 | 0.500 | 12.70 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 5 1/2" | 14.00 | 5.500 | 139.70 | 0.244 | 6.20 | PS | - | - | - | - | - | - | - |

| 15.50 | 5.500 | 139.70 | 0.275 | 6.98 | PSLB | - | - | - | - | - | - | - | |

| 17.00 | 5.500 | 139.70 | 0.304 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 20.00 | 5.500 | 139.70 | 0.361 | 9.17 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.00 | 5.500 | 139.70 | 0.415 | 10.54 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 5.500 | 139.70 | 0.500 | 12.70 | - | - | - | P | - | P | P | P | |

| 29.70 | 5.500 | 139.70 | 0.562 | 14.27 | - | - | - | P | - | P | P | P | |

| 32.60 | 5.500 | 139.70 | 0.625 | 15.88 | - | - | - | P | - | P | P | P | |

| 35.30 | 5.500 | 139.70 | 0.687 | 17.45 | - | - | - | P | - | P | P | P | |

| 38.00 | 5.500 | 139.70 | 0.750 | 19.05 | - | - | - | P | - | P | P | P | |

| 40.50 | 5.500 | 139.70 | 0.812 | 20.62 | - | - | - | P | - | P | P | P | |

| 43.10 | 5.500 | 139.70 | 0.875 | 22.22 | - | - | - | P | - | P | P | P | |

| 7" | 20.00 | 7.000 | 177.80 | 0.272 | 6.91 | PS | - | - | - | - | - | - | PS |

| 23.00 | 7.000 | 177.80 | 0.317 | 8.05 | PSLB | PLB | PLB | PLB | PLB | - | - | PLB | |

| 26.00 | 7.000 | 177.80 | 0.362 | 9.19 | PSLB | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 29.00 | 7.000 | 177.80 | 0.408 | 10.36 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 32.00 | 7.000 | 177.80 | 0.453 | 11.51 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 35.00 | 7.000 | 177.80 | 0.498 | 12.65 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 7.000 | 177.80 | 0.540 | 13.72 | - | PLB | PLB | PLB | PLB | PLB | PLB | PLB | |

| 9 5/8" | 32.30 | 9.625 | 244.48 | 0.312 | 7.92 | - | - | - | - | - | - | - | - |

| 36.00 | 9.625 | 244.48 | 0.352 | 8.94 | PSLB | - | - | - | - | - | - | PSLB | |

| 40.00 | 9.625 | 244.48 | 0.395 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | - | PSLB | |

| 43.50 | 9.625 | 244.48 | 0.435 | 11.05 | - | PLB | PLB | PLB | PLB | PLB | PLB | - | |

| 47.00 | 9.625 | 244.48 | 0.472 | 11.99 | - | PLB | PLB | PLB | PLB | PLB | PLB | - | |

| 53.50 | 9.625 | 244.48 | 0.545 | 13.84 | - | PLB | PLB | PLB | PLB | PLB | PLB | - | |

| 58.40 | 9.625 | 244.48 | 0.595 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | PLB | - | |

| 59.40 | 9.625 | 244.48 | 0.609 | 15.47 | - | - | - | P | - | P | - | - | |

| 64.90 | 9.625 | 244.48 | 0.672 | 17.07 | - | - | - | P | - | P | - | - | |

| 70.30 | 9.625 | 244.48 | 0.734 | 18.64 | - | - | - | P | - | P | - | - | |

| 75.60 | 9.625 | 244.48 | 0.797 | 20.24 | - | - | - | P | - | P | - | - | |

| 13 3/8" | 48.00 | 13.375 | 339.72 | 0.330 | 8.38 | - | - | - | - | - | - | - | - |

| 54.50 | 13.375 | 339.72 | 0.380 | 9.65 | PSB | - | - | - | - | - | - | PSB | |

| 61.00 | 13.375 | 339.72 | 0.430 | 10.92 | PSB | - | - | - | - | - | - | PSB | |

| 68.00 | 13.375 | 339.72 | 0.480 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 72.00 | 13.375 | 339.72 | 0.514 | 13.06 | - | PSB | PSB | PSB | PSB | PSB | PSB | ||