Description

Overview of Square Kelly and Hexagonal Kelly

The Square Kelly and Hexagonal Kelly is located at the uppermost end of the drill string and has two square and hexagonal shapes. In rotary table drilling, when drilling, the Square Kelly and Hexagonal Kelly is matched with the square bushing and the rotary table bushing, and the torque of the ground rotary table is delivered to the drill pipe to drive the drill bit to rotate and bear the suspended weight of the drill string. In turbine and screw drilling, the Square Kelly and Hexagonal Kelly bears the suspended weight and reactive torque of the drill string.

The Square Kelly and Hexagonal Kelly is located at the uppermost end of the column, its main function is to transmit torque, and its work is to bear the weight of the drill string. It consists of a driving part (square or hexagonal), an upper joint (left-handed thread), and a lower joint (right-handed thread). The most commonly used is the square kelly.

Square Kelly and Hexagonal Kelly is composed of upper and lower joints and pipe body. The body of the pipe is of square or hexagonal structure (most oil wells are of square structure). The upper joint is a left-handed female thread (reversed buckle), which is connected with the faucet. During the rotation, the left-handed female thread prevents reverse buckle; the lower joint is a right-handed male thread, which is connected with the drill pipe. When working, the upper end of the Square Kelly and Hexagonal Kelly is always above the surface of the turntable, and the lower part is below the surface of the turntable.

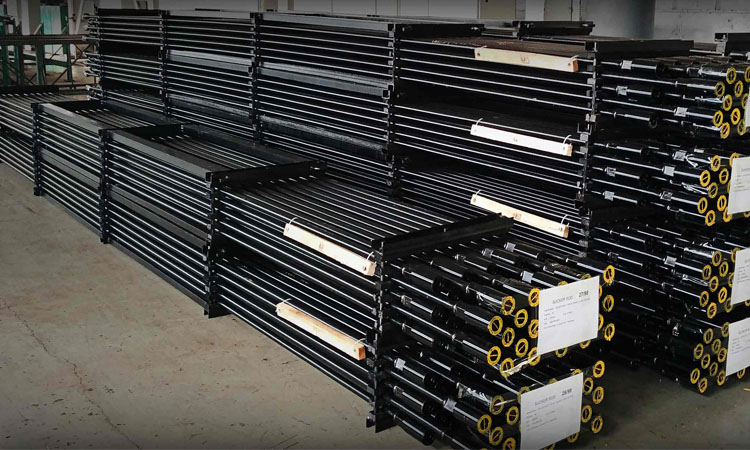

Drill collars and drill pipes are consumable and irreplaceable industrial products. They are important components and consumable parts of the drill string of oil and gas field drilling wells. For every 1 meter of drilling well, about 0.6 kg of drill collars and 1.6 kg of drill pipes are consumed respectively. . Based on the average well depth of 3,000 meters and the most widely used drill collars of 6″ (1.2 tons/piece), the domestic demand for drill collars is about 30,000 pieces per year according to the statistics of the demand of the three major oil companies, Sinopec, PetroChina, and CNOOC. , the demand for drill pipes is about 350,000 to 400,000 pieces. According to statistics, the demand for drill collars in the international market in 2016 is about 50,000 pieces, and 450,000 pieces of drill pipes; And it is growing steadily with a growth rate of more than 10% every year, and the market demand continues to grow.

Geological drilling is also included in oil drilling. Drilling an exploratory well is a kind of geological drilling. There will be methods such as taking cores and well logging to obtain geological data. Of course, the important purpose of exploratory wells in oil drilling is to find oil and gas, but some additional resources such as coal mines will also be found incidentally. In drilling, Square Kelly and Hexagonal Kelly + drill pipe + weighted drill pipe is just a configuration method. Now that the use of top drive drilling rigs is becoming more and more common, Square Kelly and Hexagonal Kelly is becoming more and more difficult to see. The top drive can drive one string of drill pipes (2 or 3) at a time, which is much more efficient than the Square Kelly and Hexagonal Kelly that can only be driven one at a time. More importantly, in terms of well control, in the event of overflow, the top drive can quickly implement well control, which greatly avoids the possibility of accidents compared with the inefficiency of Square Kelly and Hexagonal Kelly . So Square Kelly and Hexagonal Kelly will not appear in drilling with top drive. Heavy pipe is also not a requirement, especially in vertical wells, and exploration wells are often vertical (very few also have directional exploration wells). Although heavy drill pipes and drill collars can play a better role in transmitting drilling pressure than drill pipes, in vertical well operations, choosing drill collars can better improve the rigidity of the drilling tool and make the well drill straight. Of course, the weighted drill pipe can also be arranged behind the drill collar and participate in drilling together with the drill collar.

Features of Square Kelly and Hexagonal Kelly

The Square Kelly and Hexagonal Kelly is made of AISI 4145H alloy steel, and is overall heat-treated in an intermediate frequency or 20-meter horizontal resistance furnace. Excellent mechanical properties can be obtained throughout the field. The thread can be cold-rolled, copper-plated or phosphating.

1. Our kellys have been exported to Turkey, Hungary, Singapore and Middle East etc.

2. Kellys are manufactured according to API-7-1 Spec.

3. The kellys are made of AISI 4142H-4145H forged or rolled alloy structural steel

Applications of Square Kelly and Hexagonal Kelly

①During drilling, the Square Kelly and Hexagonal Kelly is matched with the bushing and the turntable bushing, and the ground rotation torque is transmitted to the drill pipe to drive the drill string and the drill bit to rotate.

② Bear the full weight of the drill string.

③ Channels for drilling fluid circulation.

Price of Square Kelly and Hexagonal Kelly

The Square Kelly and Hexagonal Kelly Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Square Kelly and Hexagonal Kelly . If you are looking for Square Kelly and Hexagonal Kelly , please kindly contact us to get the latest Square Kelly and Hexagonal Kelly price.

Square Kelly and Hexagonal Kelly Supplier

Sino Mechanical, as a Square Kelly and Hexagonal Kelly manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Square Kelly and Hexagonal Kelly . We are global Square Kelly and Hexagonal Kelly supplier. We offer a wide range of drilling equipment and have Square Kelly and Hexagonal Kelly for sale. We also provide OEM services. We design, manufacture, and sell Square Kelly and Hexagonal Kelly for your drilling applications. If you want to know latest Square Kelly and Hexagonal Kelly price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Square Kelly and Hexagonal Kelly

NOM. SIZE | TOP CONNECTION(LH) | BOTTOM CONNECTION | I.D. (IN) | DRIVE SECTION (IN) | ||||

STANDARD O.D.(IN) | OPTIONAL O.D.(IN) | SQUARE O.D.(IN) | HEX. O.D.(IN) | SQUARE | HEX. | A | B | |

2-1/2 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC26 | 1-1/4 | 3-2/7 | |||

3 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC31 4-1/8 | NC26 3-3/8 | 1-3/4 | 1-1/4 | 4 | 3-3/8 |

3-1/2 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC38 4-3/4 | NC31 4-1/8 | 2-1/4 | 1-3/4 | 4-1/2 | 4 |

4-1/4 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC46 6-1/4 | NC38 4-3/4 | 2-4/5 | 2-1/4 | 5-4/7 | 4-4/5 |

6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC50 6-3/8 | NC38 4-3/4 | 2-4/5 | 2-1/4 | 5-4/7 | 4-4/5 | |

5-1/4 | 6-5/8REG 7-3/4 | 5-1/2FH 7 | NC46 6-1/4 | 3-1/4 | 3 | 7 | 6 | |

6-5/8REG 7-3/4 | NC56 7 | NC50 6-3/8 | 3-1/4 | 3-1/4 | 7 | 6 | ||

6 | 6-5/8REG 7-3/4 | 5-1/2FH 7 | 3-1/2 | 6-4/5 | ||||

6-5/8REG 7-3/4 | NC56 7 | 3-1/2 | 6-4/5 | |||||