Description

Overview of Milling Shoes and Milling tools

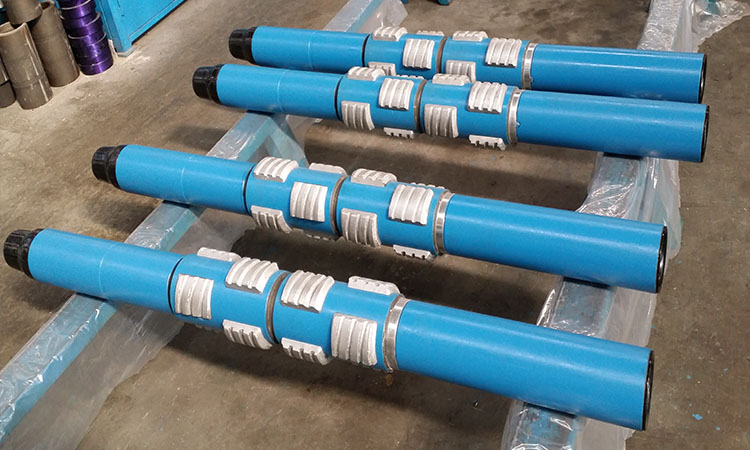

The flat-bottomed Milling Shoes and Milling tools is a tool that uses YD alloy or stable performance material on the bottom surface to grind well falling objects. Such as milling drill bits, bolts, cones, drift gauges, slips, flushing pipes, drill joints, deep well pump accessories, packers, water distributors, and long drilling tools.

According to its shape, Milling Shoes are mainly divided into collar type, sleeve milling type, flat bottom type, concave bottom type, pear type, cone type milling shoes.

Features of Milling Shoes and Milling tools

1. The milling surface is surfacing with granular cemented carbide, which is used to grind falling objects such as gear wheels, slip teeth, deep well pump accessories, etc.

2. This type of milling shoes is impact-resistant and has a long service life.

Applications of Milling Shoes and Milling tools

Milling Shoes and Milling tools are tools for grinding well fallout, such as grinding drill bits, bolts, cones, drift gauges, slips, flushing pipes, drill joints, deep well pump accessories, packers, water distributors, and long drilling tools.

Operation Method of Milling Shoes and Milling tools

1. Before going into the well, check whether the drill pipe thread is in good condition, whether the water hole is unblocked, and the YD alloy or abrasive material must not exceed the diameter of the body.

2. Connect the Flat Milling Shoes to the bottom end of the tool and go down the well.

3. Go down to 2-3m above the top of the fish, turn on the pump to flush the top of the fish first. After the flow of the flushing fluid from the wellhead is stable, start the turntable and lower the drilling tool slowly so that it touches the fish for grinding.

Precautions of Milling Shoes and Milling tools

1. The drilling speed should not be too fast.

2. Do not stop the pump during operation.

3. If there is no footage at a single point for a long time, the reason should be analyzed and measures should be taken to prevent the casing from being damaged.

4. It is not suitable to use the top of the movable fish to prevent the Milling Shoes from driving the fish to the bottom of the well or damage the fish below.

Price of Milling Shoes and Milling tools

The Milling Shoes and Milling tools Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Milling Shoes and Milling tools. If you are looking for Milling Shoes and Milling tools, please kindly contact us to get the latest Milling Shoes and Milling tools price.

Milling Shoes and Milling Shoes and Milling tools

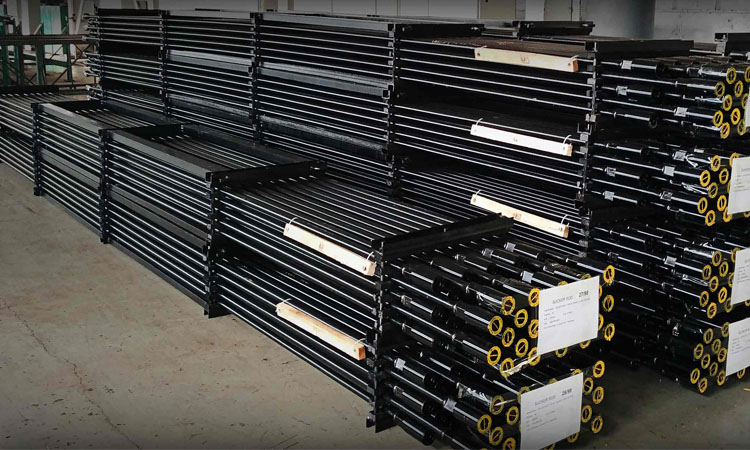

Sino Mechanical, as a Milling Shoes and Milling tools manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Milling Shoes and Milling tools. We are global Milling Shoes and Milling tools supplier. We offer a wide range of drilling equipment and have Milling Shoes and Milling tools for sale. We also provide OEM services. We design, manufacture, and sell Milling Shoes and Milling tools for your drilling applications. If you want to know latest Milling Shoes and Milling tools price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Milling Shoes and Milling tools

TYPE | O.D./IN | CONNETION | OAL/IN |

MX105 | 4-1/8 | NC23 | 3-1/2 |

MX114 | 4-1/2 | NC26 | 16 |

MX140 | 5-1/2 | 3-1/2REG | 27-1/2 |

MX152 | 6 | NC38 | 18-1/2 |

MX178 | 7 | NC46 | 19 |

MX195 | 7-43/64 | 4-1/2REG | 21-1/4 |

MX215 | 8-15/32 | 4-1/2REG | 21-1/4 |

MX311 | 12-1/4 | 6-5/8REG | 23-27/64 |

MX406 | 16 | 7-5/8REG | 25-19/32 |