Description

Overview of Measurement While Drilling

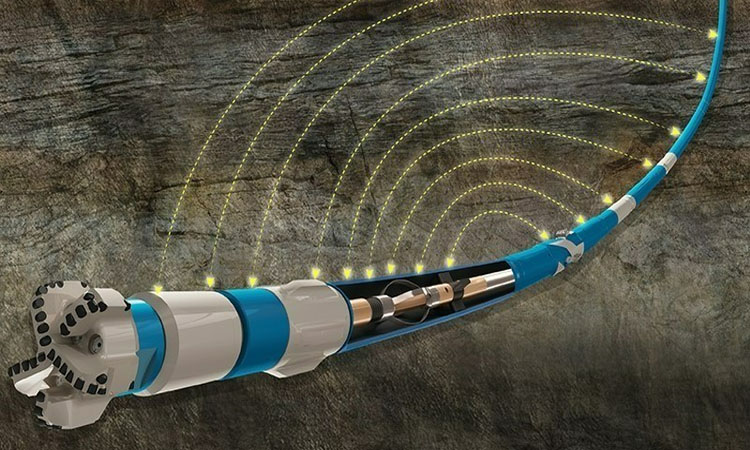

MWD (Measurement While Drilling) means that the drilling rig continuously detects the information about the drill hole or the drill bit while drilling. And it is realized by the tracking and guiding instrument. Therefore, the tracking and guiding instrument is necessary for the construction of horizontal directional drilling rigs. Logging While Drilling (LWD) is based on MWD (Measure While Drilling). And LWD will add several parameter sensors for formation evaluation, such as compensated dual lateral resistivity, natural gamma ray, Azimuth neutron density, sound wave, compensation neutron density, etc..

In recent years, the rapid development of the oil drilling industry has driven the development of related drilling exploration equipment and supporting materials. Among them, the Measurement While Drilling (MWD) wireless measurement while drilling is a very important tool in the oil drilling process which is just like the eyes of drilling. It provides ground drilling engineers with data such as azimuth, gamma, tool face and other data of complex underground well conditions at any time. Its importance cannot be overstated and metaphor.

Compared with the wired measurement while drilling, the Measurement While Drilling (MWD) wireless measurement while drilling is suitable for the wellbore trajectory measurement construction of more difficult directional wells, especially for highly deviated wells and horizontal wells. drilling.

Measurement While Drilling (MWD) wireless measurement-while-drilling instrument structural parts application materials are mainly composed of four types of alloys. Among them, the application of copper alloy is mainly based on C17200 beryllium bronze, phosphor bronze and new copper alloy copper nickel tin.

Features of Measurement While Drilling

1. Measurement While Drilling (MWD) system overview and working principle

Measurement While Drilling (MWD) refers to the process of measuring certain information near the drill bit and transmitting the information to the surface without interrupting the normal drilling operation.

Types of information:

(1) Directional data (inclination angle, azimuth angle, tool face angle).

(2) Information properties (gamma ray, resistivity logging).

(3) Drilling parameters (weight-on-bit, torque, revolutions).

The sensors are housed in special downhole instruments that are an integral part of the BHA. There is a transmitter in the downhole tool that sends a signal to the surface through some kind of telemetry channel. The most common telemetry channel in use today is the drilling fluid column within the drill string. After the signal is detected on the ground, it is decoded and processed to provide the required information in a convenient and usable manner. The biggest advantage of Measurement While Drilling (MWD) is that it can "see" what is happening downhole in real time, and the delay from measuring parameters at the bottom of the hole to receiving data on the surface is only a few minutes, so the decision-making process can be improved.

2. Signal telemetry channel

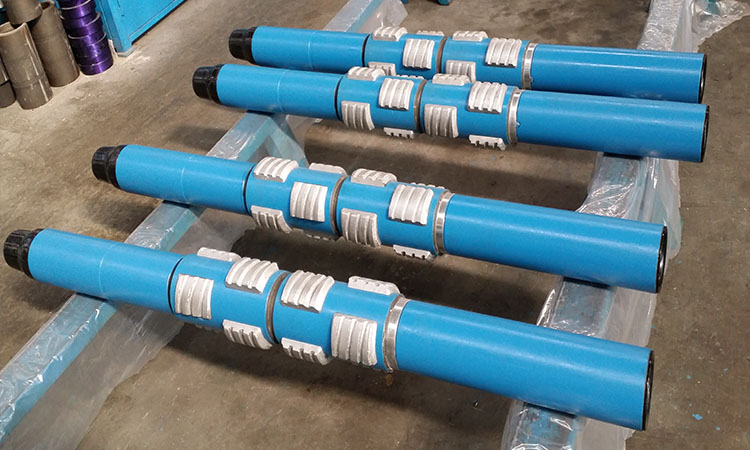

The methods for realizing Measurement While Drilling (MWD) telemetry include hard wire method, electromagnetic wave method, acoustic wave method and drilling fluid pulse method. At present, the drilling fluid pulse method is commonly used, and the pressure pulse is transmitted to the ground through the liquid column in the drill pipe at a speed of 1200-1500 m/s. All downhole components are installed in non-magnetic drill collars. To accommodate the components of the Measurement While Drilling (MWD) tool, the inside diameter is larger than that of ordinary drill collars.

3. Pulse generator

There is a downhole controller in the downhole tool of Measurement While Drilling (MWD), which is a downhole CPU composed of a single board machine, and its function is to coordinate and control various working sequences of the Measurement While Drilling (MWD) tool. The downhole controller converts the parameters measured by various downhole sensors into electrical signals, and then instructs the pulse generator to convert these signals into drilling fluid pulse signals in a specific sequence and format (encoding), and then passes through the drilling fluid column in the drill pipe to move upward. It is sent to ground sensors, signal decoding and data processing systems for signal pickup, conversion, decoding, processing, etc., for operators to analyze and make decisions.

4. Downhole power supply

There are currently two types of downhole power sources for Measurement While Drilling (MWD), namely battery packs and turbine alternators. The advantage of the battery pack is that it is compact and reliable; the disadvantage is that its life is limited and affected by temperature, and the cost of replacing the battery is also high, and its ability to transmit multiple parameters is limited. The advantage of the turbine alternator power supply is that it can provide power for the system for a long time and has a long working life, so it can transmit more parameters, which represents the development trend of measurement technology; its disadvantage is that the generated current is unstable, and a voltage stabilizer must be used Control, and once the turbine is damaged, it will cause power failure, the structure is complex, and maintenance is difficult.

5. Engineering parameter sensor

Ordinary Measurement While Drilling (MWD) is mainly used to measure the wellbore trajectory parameters, namely the inclination angle and azimuth angle, and the tool face angle (ω) when sliding drilling with downhole power drilling tools. Sensors that measure these engineering parameters are also called directional sensors.

6. Measurement While Drilling (MWD) ground system

Most Measurement While Drilling (MWD) companies use fairly similar surface equipment to interpret, record and display data measured by downhole sensors. The number of ground equipment depends on each company and the number of parameters measured. If only directional data is required, Measurement While Drilling (MWD) may require only a riser pressure transducer and a receiving/processing system that can be installed in the driller's watchroom. If formation evaluation data and drilling data are also to be measured, it is practical to house all electronics and plotting equipment in the drilling fluid logging room or in a purpose-built house on the rig floor.

Applications of Measurement While Drilling

1. Provide ground drilling engineers with azimuth, gamma, tool face and other data of complex underground well conditions

2. It is suitable for the wellbore trajectory measurement construction of more difficult directional wells, especially for highly deviated wells and horizontal wells

Price of Measurement While Drilling

The Measurement While Drilling Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Measurement While Drilling. If you are looking for Measurement While Drilling or Measurement While Drilling spares, please kindly contact us to get the latest Measurement While Drilling price.

Measurement While Drilling Supplier

Sino Mechanical, as a Measurement While Drilling manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Measurement While Drilling. We are global Measurement While Drilling supplier. We offer a wide range of drilling equipment and have Measurement While Drilling for sale. We also provide OEM services. We design, manufacture, and sell Measurement While Drilling for your drilling applications. If you want to know latest Measurement While Drilling price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Measurement While Drilling

| MWD + GAMMA Module | ||

| Features | Specs | |

| Telemetry Type | Positive Pulse | |

| Tool Outer Diameter | (1.875” ) Φ47.6mm | |

| Length of Tool | (a) Directional Only | 6.8m |

| (b) Directional & Gamma | 8.8m | |

| Max Operating Temperature | -25~150℃ | |

| Max Operating Pressure (MPa) | ≤ (20000psi) 137MPa | |

| Wireline Retrievable | Yes | |

| Measurement Accuracy | Tool Face | +/- 1.0° |

| Azimuth range | 0~360° ±1.0° | |

| Inclination range | 0~180° ±0.1° | |

| Displacement | 100-1200USGPM096.3-75.7L/S | |

| Drilling collar size | 3½”, 4¾”, 6½”, 7”, 8”, 9½”, 12” | |

| Drilling plugging agent | 40-50ppb | |

| Sand content | ≤1% | |

| Gamma Detector Type | APIGR | |

| Sensor | Scintillating crystal + Photomultiplier tube | |

| Gamma Real time | Yes | |

| Recommended Minimum Sample Period | 10 Seconds | |

| Measurement Range | 0~500API | |

| Measurement Accuracy | ±3API (0~150API) | |

| ±10API (150~500API) | ||

| Max Data Storage Capacity | 110,000 Groups | |

| Sensitivity | Better than 1.6 CPS/API | |

| Vertical Resolution | Better than 130mm | |

| Recommended Measurement Speed | ≤30 m/h | |

| Total length of the system | 6.8m (without Gamma) | |

| 8.8m (with Gamma) | ||