Description

Overview of Line Pipes

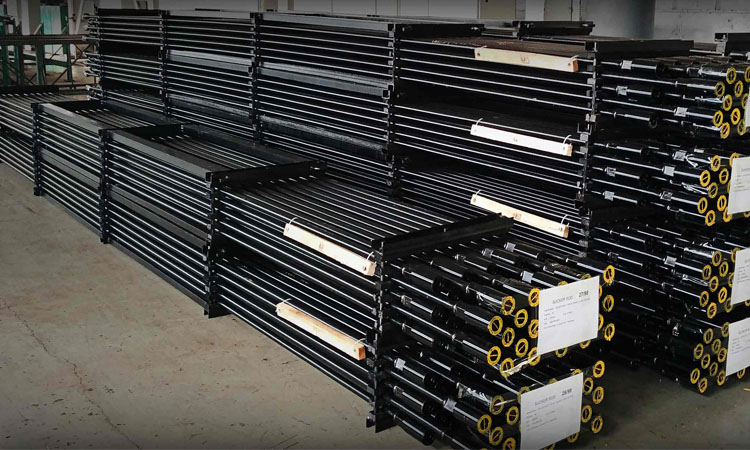

The Line Pipes pipe is to transport the oil, steam and water pumped out of the ground to the oil and gas industry enterprises through the pipeline pipe. Line pipe is a line pipe manufactured by cold rolling or hot rolling. Line pipe includes seamless and welded steel pipe with plain, threaded and socketed ends. The connection methods of the line pipe are end welding, collar connection, socket connection and so on.

The main material of line pipe is L245, L360, L418, L480, X65, X70, X80 and other steels. Steel grades of different materials have different functions.

Line Pipes are used for gas, water and oil transportation in the petroleum and natural gas industries. The line pipe produced by our company has the manufacturing capacity of high-strength line pipe, submarine line pipe, low temperature resistant line pipe, high temperature resistant line pipe, corrosion resistant line pipe and other multi-purpose and high-grade products.

Line Pipes is a type of steel used to manufacture oil and gas pipeline transportation systems. As a long-distance transportation tool for oil and natural gas, the pipeline system has the advantages of economy, safety and uninterrupted.

The many challenges faced by Line Pipes include: most of the oil and gas fields are located in polar regions, ice sheets, deserts, and ocean areas, and the natural conditions are relatively harsh; or in order to improve transportation efficiency, the diameter of the pipeline is constantly enlarged, and the delivery pressure is constantly increased; Corrosion and more.

Line pipe is mainly used to manufacture high-quality carbon structural steel, alloy structural steel and stainless heat-resistant steel seamless steel pipes for steam boiler pipes with high pressure and above pressure. These boiler pipes work under high temperature and high pressure. Oxidation and corrosion will also occur under the action of high-temperature flue gas and water vapor. Therefore, the steel pipe is required to have high durable strength, high oxidation resistance, and good structural stability. The steel grades used are: high-quality carbon structural steel The steel grades are 20g, 20mng, 25mng; the steel grades of alloy structural steel are 15mog, 20mog, 12crmog, 15crmog, 12cr2mog, 12crmovg, 12cr3movsitib, etc.; Do the hydrostatic test one by one, and do the flaring and flattening tests. Steel pipes are delivered in a heat-treated state. In addition, there are certain requirements for the microstructure, grain size and decarburization layer of the finished steel pipe. Seamless steel pipes for geological drilling and oil drilling control; use drilling rigs to drill wells to find out the structure of underground rock formations, groundwater, oil, natural gas and mineral resources. The exploitation of oil and natural gas is inseparable from well drilling. Seamless steel pipes for oil drilling for geological drilling control are the main equipment for drilling, mainly including core outer pipes, core inner pipes, casings, drill pipes, etc. Since the drilling pipe has to work deep into the formation depth of several thousand meters, the working conditions are extremely complicated. The drill pipe is subjected to stresses such as tension, compression, bending, torsion and unbalanced impact loads, and is also subject to mud and rock wear. Therefore, pipes are required It must have sufficient strength, hardness, wear resistance and impact toughness. The steel used for steel pipes is represented by "dz" (geological Chinese pinyin prefix) plus a number one to represent the yield point of the steel. The commonly used steel grades are 45mnb and 50mn of dz45; 40mn2, 40mn2si of dz50; 40mn2mo, 40mnvb of dz55; 40mnmob of dz60, 27mnmovb of dz65. Steel pipes are delivered in a heat-treated state. Petroleum cracking tubes: seamless tubes for furnace tubes, heat exchanger tubes and pipelines used in petroleum refineries. Commonly used high-quality carbon steel (10, 20), alloy steel (12crmo, 15crmo), heat-resistant steel (12cr2mo, 15cr5mo), stainless steel (1cr18ni9, 1cr18ni9ti) manufacturing. In addition to the chemical composition and various mechanical properties of the steel pipe, it is also necessary to ensure the water pressure, flattening, flaring and other tests, as well as surface quality and non-destructive testing. Steel pipes are delivered in heat-treated condition. Stainless steel pipes: hot-rolled and cold-rolled stainless steel pipes of various stainless steels are widely used in petroleum, chemical equipment pipelines and stainless steel structural parts for various purposes. In addition to ensuring chemical composition and mechanical properties, steel pipes used to withstand fluid pressure To ensure that the hydrostatic test is qualified. All kinds of special steel pipes shall be guaranteed according to the regulations.

Line pipe is a type of steel pipe that is used to transport petroleum, natural gas, oil, water, etc.

This pipe is available in a variety of diameters ranging from 2 inches to 48 inches and there are two product specification levels PSL 1 & PSL 2.

Line pipe can include either seamless or welded carbon steel or stainless steel piping. Because line pipe needs to withstand high pressures. There are important tests done on line pipe to ensure it meets all of the requirements of steel chemistry, strength, toughness, and dimensional characteristics. Using line pipe that meets the set criteria will ensure safe and reliable pipeline service.

The processing for welded line pipe includes ERW, LSAW, SSAW, DSAW, etc.

All welded pipe and seamless pipe will be supplied with mill test reports and full traceability as required.

And many grades of line pipe can be supplied, including API 5L-B, X-42, X-46, X-52, X-60, X-70, X-80, etc., manufactured according to standards of API 5L, ISO3183, ASTM A53, ASTM A106, ASTM A134, ASTM A135, ASTM A333, ASTM A335, etc.

In 2017 & 2018, we exported more than 10000tons LSAW to UZ National Oil Company.

Features of Line Pipes

From the comprehensive evaluation of the development trend of oil and gas pipelines, pipeline laying conditions, main failure modes and failure causes, pipeline steel should have good mechanical properties (thick wall, high strength, high toughness, wear resistance), and should also have large diameter, Weldability, cold and low temperature resistance, corrosion resistance (CO 2 ), seawater resistance, HIC, SSCC performance, etc.

① High strength. Pipeline steel not only requires high tensile strength and yield strength, but also requires the yield ratio to be in the range of 0.85~0.93.

② High impact toughness. High impact toughness can meet the requirements of preventing cracking.

③Low ductile-brittle transition temperature. Harsh regions and climate conditions require pipeline steel to have a sufficiently low ductile-brittle transition temperature. The shear area of DWTT (Drop Weight Tear Test) has become the main control index to prevent brittle failure of pipelines. The general specification requires that the fracture shear area of the specimen be ≥85% at the lowest operating temperature.

④Excellent resistance to hydrogen-induced cracking (HIC) and sulfide stress corrosion cracking (SSCC)

⑤ good welding performance. Good weldability of steel is very important to ensure the integrity and welding quality of the pipeline.

6. Good corrosion resistance, good ductility and bearing capacity.

Applications of Line Pipes

Line Pipes are used for gas, water and oil transportation in petroleum and natural gas industry. Because of its excellent bearing capacity, hardness and other properties, it can be trusted by people when it is used.

Engineering line pipe performance and use classification:

(1) Water supply pipelines: including industrial water supply, domestic water supply, fire water supply and other pipelines

(2) Drainage pipes: including industrial sewage (wastewater), domestic sewage, rainwater, lower groundwater and other pipes and open ditches.

Price of Line Pipes

The Line Pipes Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Line Pipes. If you are looking for Line Pipes or Line Pipes spares, please kindly contact us to get the latest Line Pipes price.

Line Pipes Supplier

Sino Mechanical, as a Line Pipes manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Line Pipes. We are global Line Pipes supplier. We offer a wide range of oilfield equipment and have Line Pipes for sale. We also provide OEM services. We design, manufacture, and sell Line Pipes for your applications. If you want to know latest Line Pipes price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Line Pipes

Type of Steel Pipe & their application | |||

Product | Standard | Steel Grade | Application |

Line Pipe | API 5L, ASTM A53/A106, DIN1629, JIS G3454, JIS3466 | A, B, X42, X46, X52, X56, X60, X65, X70, St37, ST52 | Transmission of the petroleum, natural gas and water |

Structure Pipe | ASTM A53/A106, GB8162 | A, B, 20#, 45#, Q345, 20Mn2, 42CrMo | Used for producing mechanical parts and pipe fittings |

Hydraulic Tube | GB17396 | 35#, 45#, 27SiMn, 20CrMo4, 30CrMo4 | Mining machinery |

Oil Cracking Tube | ASME SA213, GB9948 | T5, T9, 20#, 16Mn, 12CrMo, 15CrMo | Used in petroleum cracking furnace |

Chemical Pipe | GB6479 | 20#, 16Mn, 12CrMo, 15CrMo | High pressure chemical equipment and tube |