Description

Overview of Hole Openers

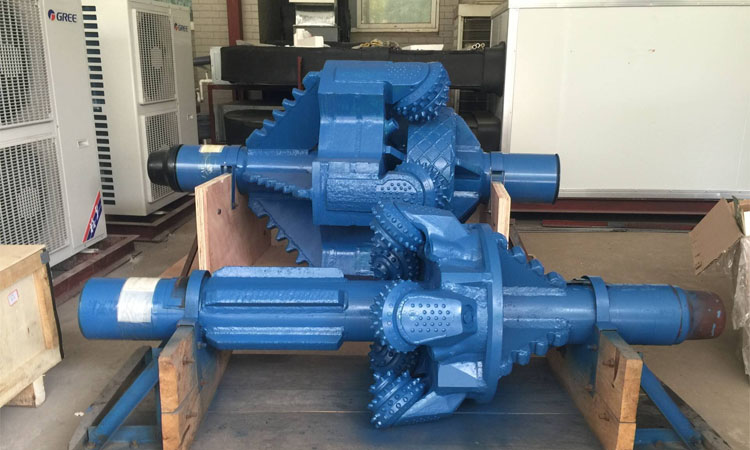

The fixed-diameter hole opener is used for reaming large holes in the surface layer of land oilfields and offshore oilfields. It is used to expand the pre-drilled hole of the roller cone bit, or connected to the drill bit to complete drilling and reaming operations at the same time. Hole Opener is used to enlarge the diameter of pre-drilled hole or connected with a bit on front end to drill pilot hole and enlarge hole simultaneously.

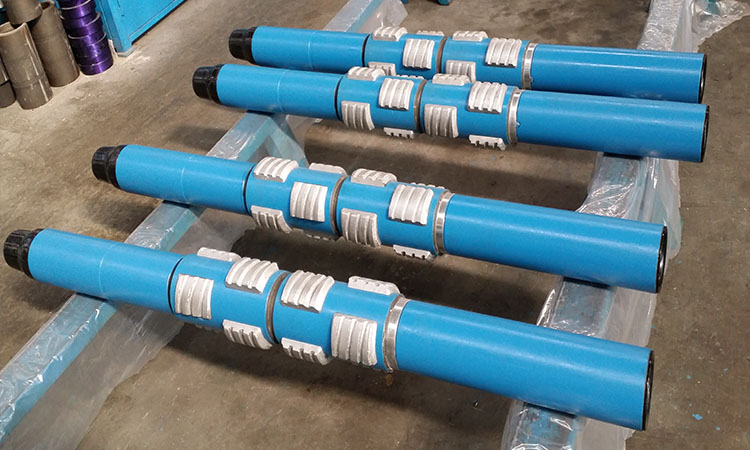

A hole opener is a fixed diameter tool that is commonly used in drilling larger top hole sections where there are no restrictions. Hole openers are used in all facets of drilling a well for actually enlarging the hole, to act as a stabilizer, or to use for a wiper trip (ensure hole is to gauge). Hole openers usually are run with roller cones but as the hole sizes get smaller, some people prefer to use a bladed hole opener which does not use roller cones.

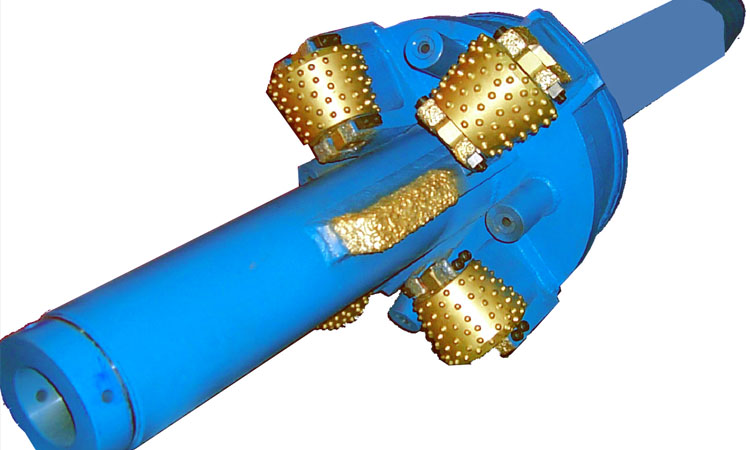

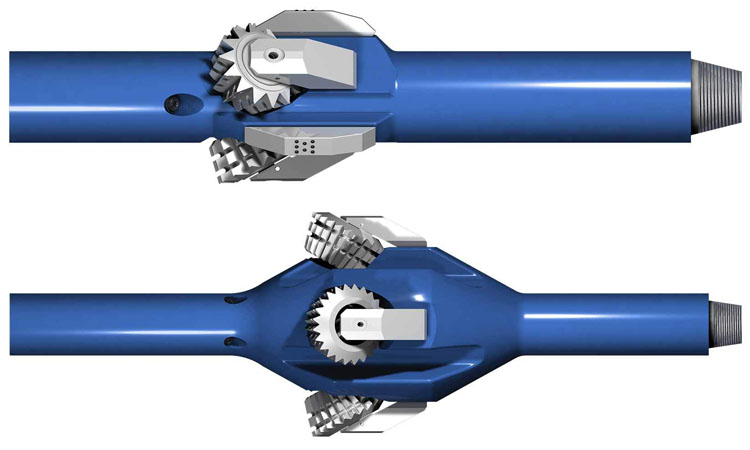

Hole openers are used to increase size of well bore and there are two broad categories of hole openers: fixed diameter hole openers, and under-reamers. Fixed diameter hole openers are usually made up of three “cutters” arranged around a mandrel, and mounted on “saddles” by strong retaining pins. Cutters may be milled tooth, PDC, or TC inserts, which will vary depending on the formation to be cut. Under-reamers, on the other hand, are hydraulically actuated hole openers that possess two or three arms. They are primarily used when a hole needs to be opened to a diameter larger than the casing which has already been set. Both of these forms typically feature a series of fluid passages, or “jets”, which are arranged to keep the cutters lubricated and help with the removal of cuttings. These need to be set up properly before use, to ensure a balanced mud flow both through and out of the hole opener.

Features of Hole Openers

A hole opener is a cost effective way to enlarge a pre-drilled pilot hole or to ensure that the gauge is maintained in a deviated hole. A hole opener with a bull nose below helps to mitigate any potential side track issues in wiper trip applications.

1. Cantilevered Design for Less Drag

2. Field Interchangeable Cutters. Replacing Cutters and Cutting Cost - On most Hole Opener designs, the cutters can be easily replaced. The cost to replace a cutter is a fraction of the cost to replace a large tricone rock bit.

3. Single Body for Multiple Hole Sizes

4. Custom Design with More Cutters on Larger Hole Sizes

5. Flexability - Hole Openers can be fabricated in just about any size, and can be configured to drill through any formation.

6. Hole Opener with fully heat-treated alloy steel is available with carbide-milled teeth and insert cutters.

7. Hole Opener's arms and cutters are hardfaced for protection in three different designs for varying conditions and rock formations.

Applications of Hole Openers

The hole opener is generally used after the pilot bit has drilled the original hole. A hole opener consists of a body with roller cones or it could be a fixed blade that would be dressed with PDC or crushed Carbide.

Price of Hole Openers

The Hole Openers Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Hole Openers. If you are looking for Hole Openers, please kindly contact us to get the latest Hole Openers price.

Hole Openers Supplier

Sino Mechanical, as a Hole Openers manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Hole Openers. We are global Hole Openers supplier. We offer a wide range of drilling equipment and have Hole Openers for sale. We also provide OEM services. We design, manufacture, and sell Hole Openers for your drilling applications. If you want to know latest Hole Openers price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Hole Openers

HOLE OPEN DIAMETER | QTY OF CUTTERS | MIN. PILOT HOLE | FISHING NECK DIAMETER | ID | TOP CONNECTION (PIN) | BOTTOM CONNECTION (BOX) | OVERALL LENGTH |

12 1/4" | 3 | 8 1/2" | 8" | 1 1/2" | 6 5/8 REG | 6 5/8 REG | 55" |

16 | 3 | 10" | 9 1/2" | 2 1/4" | 7 5/8 REG | 6 5/8 REG | 59" |

17 1/2" | 3 | 10" | 9 1/2" | 2 1/4" | 7 5/8 REG | 6 5/8 REG | 59" |

22" | 3 | 12 3/4" | 9 1/2" | 2 1/3" | 7 5/8 REG | 6 5/8 REG | 69" |

23" | 3 | 12 3/4" | 9 1/2" | 3" | 7 5/8 REG | 6 5/8 REG | 69" |

24" | 3 | 14" | 10" | 3" | 7 5/8 REG | 7 5/8 REG | 69" |

26" | 3 | 17 1/2" | 10" | 3" | 7 5/8 REG | 7 5/8 REG | 69" |

36" | 4 | 26" | 10" | 3 1/2" | 7 5/8 REG | 7 5/8 REG | 87" |