Description

Overview of Drilling Stabilizer

Drilling stabilizer (also known as centralizer) is an important tool to prevent the change of well deviation in oil, natural gas and geological exploration drilling engineering. Install a number of drilling stabilizers is to improve the quality of the well bore and the drilling speed and reduce the drilling cost.

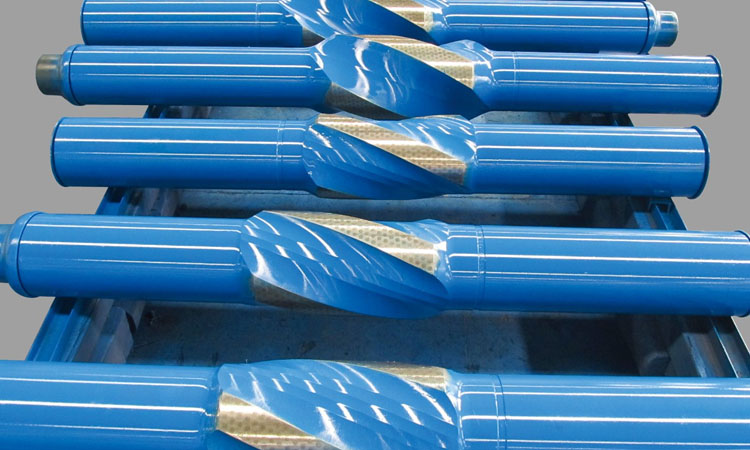

Drilling stabilizers concentrate the weight of the drill collars on the bit, stiffen the BHA, and keep the drill collars away from the borehole wall, thus reducing the risk of stuck pipe. The drilling stabilizer is composed of a hollow cylindrical body and stabilizing blades, both made of high-strength steel. The Stabilizer blades can be either straight or spiraled and are hard-faced for wear resistance. The major driver for Drilling Stabilizer Market is the demand for increasing well-drilling efficiency and minimizing well cost.

The drilling stabilizer is a cylinder with a spiral centralizing edge band, and the surface of the stabilizer spiral centralizing band is inlaid with wear-resistant alloy materials.

There are four kinds of materials for the working surface of the stabilizer:

① The surface is inlaid with carbide columns.

② The surface is inlaid with diamond composites.

③ Surface low temperature brazing carbide block.

④ Surface surfacing electrodes.

All downhole drilling stabilizers (including spiral blade, straight blade, integral blade, welded blade, sleeve-type, and stainless steel nonmagnetic types) are designed to meet or exceed the strictest quality control and quality assurance standards.

All alloy downhole drilling stabilizers are manufactured from AISI 4145H modified heat-treated steel for a wide variety of configurations and hole sizes.

Types of Downhole Drilling Stabilizers

According to the structure, the Downhole Drilling Stabilizers can be divided into: integral helical stabilizer, integral straight edge stabilizer, roller stabilizer, replaceable sleeve helical stabilizer and variable diameter stabilizer, etc.. According to different installation positions, Downhole Drilling Stabilizers can be divided into well bottom type and drill string type.

1. Integral spiral drilling stabilizer: divided into integral three-helix and four-helix stabilizers. The materials on the working surface include surface-embedded carbide columns, surface-embedded diamond composites, surface low-temperature brazing carbide blocks, and surface surfacing electrodes. kind of form.

2. Integral straight edge drilling stabilizer: overall three, four edge, multi-edge straight edge stabilizer, its working surface is inlaid with cemented carbide composites and surfacing, etc., the main body is made of alloy steel after heat treatment

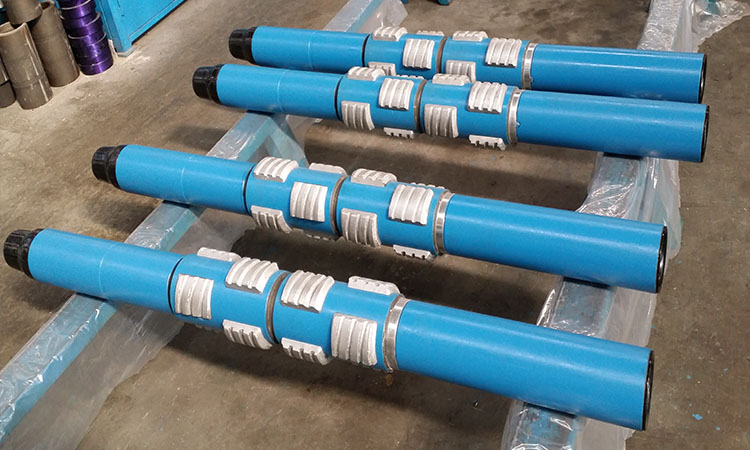

3. Replaceable sleeve drilling stabilizer (WH type): The replaceable sleeve stabilizer is an important tool to prevent the change of well deviation in oil, gas and geological exploration drilling engineering. Under the circumstances of the application, the rational use of the stabilizer can reduce the rate of change of well deviation and azimuth, which can avoid "dog legs", improve the quality of well depth and drilling speed, and reduce drilling costs. By replacing the centralizing sleeve, it can adapt to different well diameters and improve the service life. The replaceable sleeve stabilizer is composed of a main body, a stabilization sleeve and a sheath. Its advantage is that the centralizing body can be quickly replaced after the centralizing surface wears out, which can greatly save drilling costs, and is especially suitable for drilling directional wells.

Features of Drilling Stabilizer

1. Made of high-grade high-quality chrome-molybdenum alloy steel (except non-magnetic).

2. After a special heat treatment process to achieve the expected hardness, strength and impact resistance.

3. Welded straight blade for drilling soft formations

4. The thread of the stabilizer is manufactured in accordance with API specifications

5. The wear-resistant layer is made of inlaid columnar tungsten carbide cemented carbide or other types of wear-resistant materials to achieve the purpose of protecting the supporting body.

6. Sleeve type allowing less equipment inventory in remote locations

7. The non-magnetic stabilizer is inlaid with degaussed hard alloy.

8. The sleeve stabilizer is composed of a body and a sleeve. Its characteristic is that the helical rib can be replaced with a new one after wear. The material of the body is AISI4145H alloy steel, its full length after heat treatment has a Brinell hardness of 285~341, and its impact energy is ≥54J

9. Integral spiral blade allowing 360° hole contact for use in hard rock formations

10. The replaceable sleeve stabilizer is made of AISI4145H alloy steel, and the entire length has been heat-treated. The replaceable sleeve stabilizer is composed of three parts: the joint stabilizer sleeve mandrel. For each stabilizer body, it can There is a range of stable sleeves to go with it.

11. Nonmagnetic stabilizers for applications requiring magnetic isolation

12. The material used for the straight-edge stabilizer is high-grade high-quality chrome-molybdenum alloy steel, which is made of an integral bar. The stabilizer has four straight edges, and the wear-resistant layer on it is to use inlaid columnar tungsten carbide hard alloy or other types of wear-resistant materials to achieve the purpose of protecting the supporting body.

13. Sizes and configurations can be manufactured to operator’s requirements, including blade sizes, connections, and types of material.

14. All stabilizer connections can be configured as box x box, as pin x box, or as the operator requires.

15. Welded straight blade for drilling soft formations.

Applications of Drilling Stabilizer

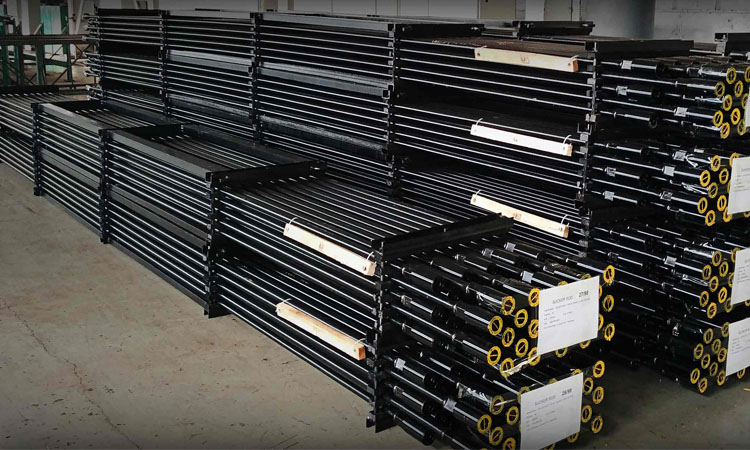

We supply a complete line of downhole drilling stabilizers to increase rate of penetration and control hole deviation problems. All these stabilizers (including drill bit type, drill string type, spiral blade, straight blade, integral blade, welded blade, sleeve-type, and stainless steel nonmagnetic types) are designed to meet the strictest quality control and quality assurance standards (API SPEC.). All alloy stabilizers are manufactured from AISI 4145H modified heat-treated steel for a wide variety of configurations and hole sizes.

1. An important tool to control well deviation parameters in drilling engineering.

2. It is suitable for stabilizing drilling tools in the drilling process of oil, natural gas and geological exploration.

3. Increase bit life with effective stabilization.

4. Improve drilling speed and well quality.

Price of Drilling Stabilizer

The Drilling Stabilizer Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Drilling Stabilizer. If you are looking for Drilling Stabilizer for your drilling operation, please kindly contact us to get the latest Drilling Stabilizer price.

Drilling Stabilizer Supplier

Sino Mechanical, as a Drilling Stabilizer manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Drilling Stabilizer. We are global Drilling Stabilizer supplier. We offer a wide range of drilling equipment and have Drilling Stabilizer for sale. We also provide OEM services. We design, manufacture, and sell Drilling Stabilizer for your drilling applications. If you want to know latest Drilling Stabilizer price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Drilling Stabilizer

HOLE SIZE (Inch) | BODY OD (Inch) | FISHING NECKLENGTH (Inch) | LBLADE LENGTH (Inch) | BLADE WIDTH(Inch) | TONG SPACE(Inch) | BORE (Inch) | OAL LENGH (FT) |

8 | 4 3/4 | 30 | 15 | 3 | 25 | 2 1/4 | 72 |

8 1/2 | 6 1/2 | 30 | 18 | 3 | 27 | 2 13/16 | 78 |

12 1/4 | 8 | 30 | 18 | 3 1/2 | 28 | 2 13/16 | 83 |

12 1/4 | 9 1/2 | 30 | 18 | 3 1/2 | 28 | 3 | 83 |

14 3/4 | 8 | 30 | 18 | 3 1/2 | 30 | 2 13/16 | 90 |

14 3/4 | 9 1/2 | 30 | 18 | 3 1/2 | 30 | 3 | 90 |

16 | 9 1/2 | 30 | 18 | 3 1/2 | 30 | 3 | 92 |

17 1/2 | 8 | 30 | 20 | 3 1/2 | 30 | 2 13/16 | 94 |

17 1/2 | 9 1/2 | 30 | 20 | 3 1/2 | 30 | 3 | 94 |

20-26 | 9 1/2-11 | 30 | 22 | 4 | 30 | 3 | 110 |