Description

Overview of Drill Pipe

The drill pipe, also called drill stem and drill rod, is a steel pipe with threads at the end, which is used to connect the surface equipment of the drilling rig and the drilling and grinding equipment or the bottom hole device at the bottom of the drilling well. The purpose of the drill pipe is to transport the drilling mud to the drill bit and together with the drill bit to raise, lower or rotate the bottom hole device. Drill pipe must be able to withstand enormous internal and external pressure, twisting, bending and vibration. In the process of oil and gas extraction and refining, the drill pipe can be used many times. Drill pipe is mainly suitable for drilling operations of deep wells, horizontal wells and extended-reach wells in the process of oil and gas exploration and development. Its main function is to transmit torque and transport drilling fluid, and the wellbore is continuously deepened by the gradual lengthening of the drill pipe. Therefore, drill pipe plays a very important role in oil drilling.

In the oil field drilling engineering, the oil drill pipe is the main part of the ground rotation system, lifting system, circulation system, drill collar and drill bit. Through them, the turntable drives the drill bit to rotate, the hook drives the drill bit to lift, and the mud is sent to the bottom of the well to form a circulation. , so that the drill bit breaks the rock formation and drills continuously. Drill pipe is the basic component of the drill string.

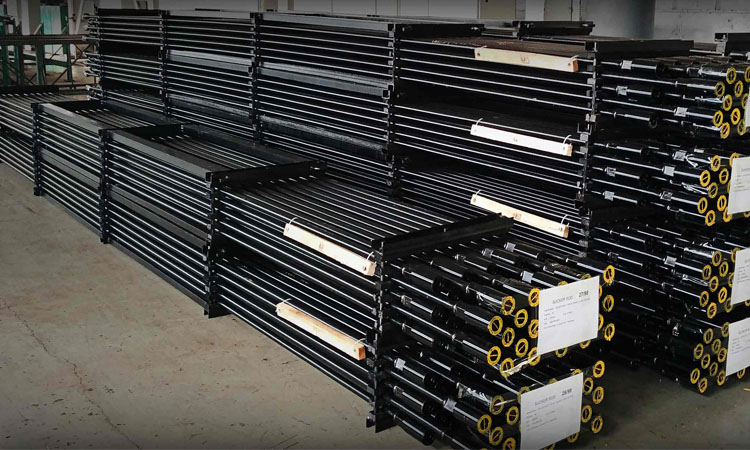

Plain and raw steel pipe is made into drill pipe after several processing steps. First, through the steel pipe thickening process, the outer surface of the bare pipe is bent inward, and the steel pipe wall is thickened. Next, it is threaded and plated with copper for added strength. Non-destructive quality control inspections are then performed, followed by welding of the steel pipe body joints. Then, the pipe will undergo welding heat treatment and welding final treatment to eliminate welding residual stress. Before the finished drill pipe is painted and packaged, other tests are carried out on the finished steel pipe, including hardness test, pressure test and non-destructive test. The length of the drill pipe is generally about nine meters.

The steel grade of the drill pipe refers to the grade of the drill pipe steel, which is determined by the yield strength of the drill pipe steel. Drill pipe steel grades are divided into five grades: D, E, 95(X), 105(G), 135(S). The higher the steel grade of the drill pipe, the greater the yield strength of the pipe, and the greater the various strengths of the drill pipe. In the strength design of the drill string, it is recommended to use the method of increasing the steel grade to improve the strength of the drill string instead of increasing the thickness of the wall.

The integral auger drill pipe has good comprehensive mechanical properties, strong hole-forming ability and long service life. It can replace the welded auger drill pipe for air pressure drilling in soft coal seams, and can also replace the conventional outer flat drill pipe for rock drilling hole.

We could supply a huge quantity of new drill pipe for sale, available in all standard sizes and weights, to quickly meet the drilling equipment needs of companies in the oil, gas and Geothermal industry.

Features of Drill Pipe

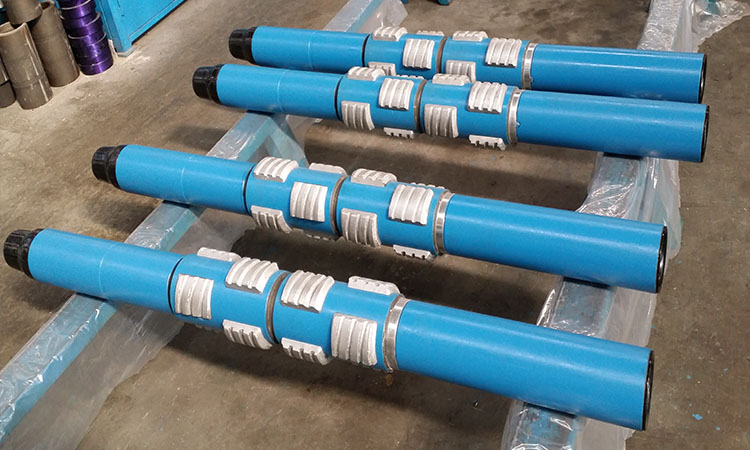

1. Drill pipe structure The drill pipe is made of seamless steel pipe, and the wall thickness is generally 9-11mm. The drill pipe is composed of two parts: the drill pipe body and the drill pipe joint. The pipe body and the joint are butt welded together by friction welding.

2. The auger rod is cold-drawn to form the blade once, without annealing, with good toughness and durability.

3. Long auger rod: cold-drawn one-time forming blade, no annealing, good toughness and durability.

4. The drill pipes of the pile driver equipment are connected by plug-in threads, which are convenient and quick to disassemble, have good sealing performance, high tensile strength, and high pile quality. Good verticality, easy to disassemble and install.

5. Lightweight, thin-walled ultra-high-strength steel drill pipe can be used to solve the drilling problems of extended-reach wells, ultra-deep wells and deep-water drilling

6. The unique heat treatment process makes the drill pipe not only meet the requirements of yield strength but also meet the requirements of toughness

7. Optimize the taper to meet the needs of drill pipe connection speed and torque transmission

8. Light weight. For deep wells, the reduced weight of the drill string means that a deeper distance can be drilled using the existing drilling rig capacity.

9. High strength-to-gravity ratio, strong corrosion resistance and high fatigue strength.

10. The drill rods comply with the provisions of API SPEC 5D & API SPEC7.

11. The raw material grade of steel are determined according to the requirements of Group 1 & Group 3 of API SPEC 5D.

12. Drill pipe joints at the same level comply with the provisions under the Standard API SPEC 7.

Drill Pipes consist of

The drill pipe joint is an integral part of the drill pipe, divided into male joints and female joints, connected to both ends of the drill pipe body. In order to enhance the connection strength of the joint, it is necessary to increase the wall thickness of the pipe body at the joint. According to the thickening method, it can be divided into three types: inner thickening, outer thickening, and inner and outer thickening. There are threads (coarse thread) on the joint, which are used to connect each single drill pipe. The thread of the drill pipe joint is a tapered pipe thread with a sealing shoulder. The shoulder surface is tightened to seal, and the thread is only used for connection. The thickening method is different, the corresponding connection.

Applications of Drill Pipe

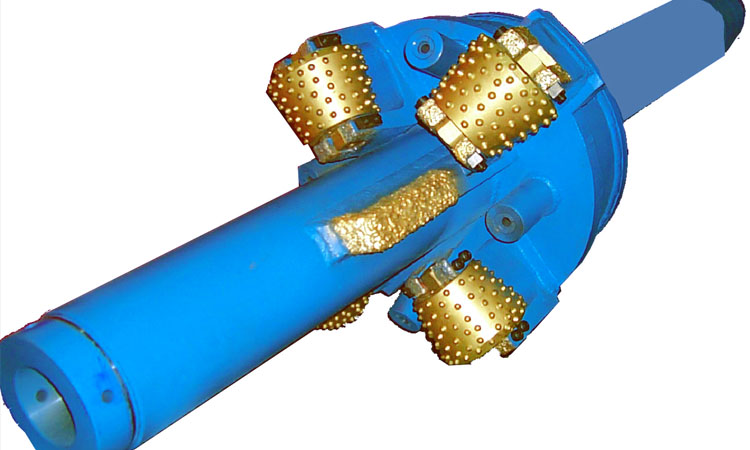

1. Pull out the drill bit.

2. Add drilling pressure.

3. Transmission power.

4. Transport drilling fluid.

5. Carry out special operations: squeeze cement, deal with underground accidents, etc.

Causes of Drill Pipe damage during drilling

1. Vibration, bending wear

When the drill string reaches the critical speed, the drill pipe will vibrate from time to time, and this vibration often causes the drill pipe to bend, excessive wear, rapid damage and fatigue failure. Especially when the two types of vibration (node vibration and spring pendulum vibration) overlap in the drill pipe, it is the most unfavorable. Critical speed varies with drill tool length, drill tool size, drill collar size and borehole size.

2. Tensile failure

Tensile failure often occurs during the pulling of stuck drill pipe. When the pull-up force exceeds the yield point, a "thin neck" deformation occurs at the weakest part or smallest section of the drill pipe wall. If the lifting force exceeds the limit strength just now, the drill pipe will be broken. Tensile failure generally occurs in the upper part of the drill string. Because the upper drilling tool not only bears the pressure, but also bears the weight of the drill string.

3. Fatigue damage

Fatigue failure is the most common type of drill pipe failure. The three basic types of fatigue damage are pure fatigue damage, notch fatigue damage and corrosion fatigue damage.

Drill pipe is subject to cyclical stresses of tension, compression, torsion and bending. Stretching and bending are the most dangerous stresses. At present, the main cause of drill pipe fatigue failure is the cyclical stress that occurs when the drill pipe rotates in a curved wellbore. In a curved wellbore, even if the drill collar has sufficient thickness, fatigue failure may still occur, and the location of the failure is not certain. When the drill pipe is bent, every time the drill pipe rotates, its corresponding position will generate periodic stress due to repeated tension and compression. The drill pipe near the drill collar is most likely to be bent, because the drill collar has greater rigidity and can resist bending, and the bend will occur on the drill pipe above the drill collar. At the same time, the maximum stress on the drill pipe occurs at the end of the thickened part of the drill pipe, about 50 cm away from the joint. As mentioned above, the joint cannot be bent, and the bending can only occur on the drill pipe body with a thinner pipe wall. At the position where the section changes, it acts like a vise to fix it, making it the fulcrum of the bending force. If the drill pipe is bent uniformly over its entire length, the stresses acting on the drill pipe will be lower and the number of stress cycles to fatigue failure can be increased.

The imperfection of the drill pipe surface, whether formed by machining or metallurgical process, will greatly affect the fatigue limit of the drill pipe, and the degree of influence depends on the location, direction, shape and number of defects. If the notch is located on the drill pipe where the main stress does not act, it will have little effect on fatigue failure. However, if the notch is located within 50 cm from the joint, it will become the core of fatigue failure because this part is where the maximum bending stress of the drill pipe occurs. The longitudinal notches can spread the stress without harm. However, even a slight nick with a sharp base corner increases stress and leads to failure.

Corrosion fatigue damage is the common cause of early failure of drill pipes. Corrosion can cause extremely serious damage in various or several combined forms of damage (erosion, wear, fatigue). Sometimes, several forms of corrosion will occur simultaneously, but generally speaking, one form of corrosion will always be the main cause of damage.

Price of Drill Pipe

The drill pipe Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price drill pipe. If you are looking for drill pipe, please kindly contact us to get the latest drill pipe price.

Drill Pipe Supplier

Sino Mechanical, as a drill pipe manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of drill pipe. We are global drill pipe supplier. We offer a wide range of drilling equipment and have different types of drill pipe for sale. We also provide OEM services. We design, manufacture, and sell drill pipe for your drilling applications. If you want to know latest drill pipe price or get drill pipe specifications, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Drill Pipe

SIZE | NOMINAL MASS | CALCULATED WEIGHT | GRADE | WALL THICKNESS | UPSET ENDS (SEE NOTE) FOR WELD-ON TOOL JOINT | ||||

In. | Mm | Lb/Ft | Kg/m | In. | Mm | ||||

2 3/8 | 60.3 | 6.65 | 6.26 | 9.32 | E,X,G,S | 0.280 | 7.11 | EU | |

2 7/8 | 73.0 | 10.4 | 9.72 | 14.48 | E,X,G,S | 0.362 | 9.19 | EU, IU | |

3 1/2 | 88.9 | 9.50 | 8.81 | 13.12 | E | 0.254 | 6.45 | EU, IU | |

4 | 101.6 | 14.00 | 12.93 | 19.26 | E,X,G,S | 0.330 | 8.38 | EU, IU | |

4 1/2 | 114.3 | 13.75 | 12.24 | 18.23 | E | 0.271 | 6.88 | EU, IU | |

5 | 127.0 | 16.25 | 14.87 | 22.15 | X,G,S | 0.296 | 7.52 | IU | |

5 1/2 | 139.7 | 21.90 | 19.81 | 29.51 | E,X,G,S | 0.361 | 9.17 | IEU | |

Note: | EU - External upset,IU - Internal upset,IEU -Internal & External upset | ||||||||