Description

Overview of Drill Collars

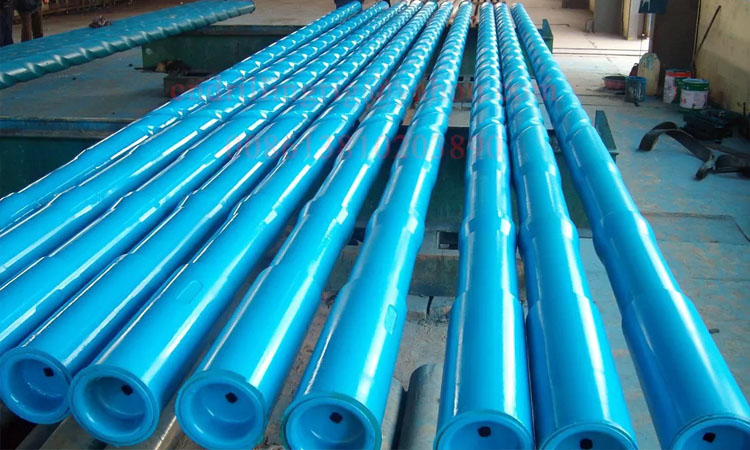

Drill Collars are integral heavy-wall joints that are manufactured from a solid bar of modified alloy steel. The solid bars are quenched and tempered to obtain the required mechanical properties, then trepanned, drifted and threaded. All drill collars are heat-treated with hardness within 285 to 341 BHN, which are guaranteed one inch below the surface of the pipe.

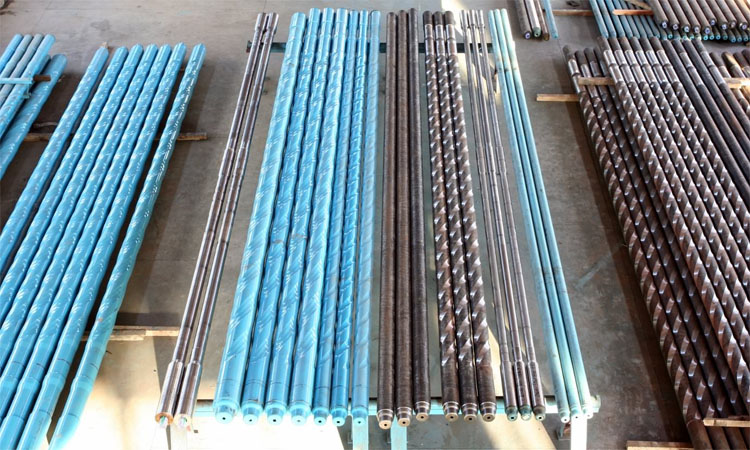

We could supply slick type drill collar, spiral drill collar and Non-magnetic drill collar (NMDC).

During the drilling process, the drill collar is mainly used to provide drilling pressure for the drill bit, keep the drill pipe in a tensioned state, and use its greater rigidity to support the drill bit and maintain the wellbore trajectory. Since the drilling pressure is formed by the weight of the drill string, the lower part of the drill string is under compressive stress. When drilling, the weight-on-bit value generally suffered is greater than the pressure bar stability critical value of the drill string, so the drill string at the lower pressure part will bend under its own weight. The curved drill string will cause alternating stress when rotating, resulting in fatigue failure of the drill string. In order to reduce the degree of fatigue damage, the bending stress should be reduced. This requires shortening the length of the compression section as much as possible and increasing its rigidity. therefore. Drill collars are used instead of drill pipes for the pressure-bearing part of the lower end of the drill string.

Spiral drill collars and non-magnetic drill collars are special drill collars in drill collars. Among them, three spiral grooves are processed on the cylindrical surface of the overall drill collar to reduce the contact area of the well wall. Spiral drill collars can effectively prevent pressure difference. and stuck drill. Non-magnetic drill collars are mainly used for monitoring during oil drilling.

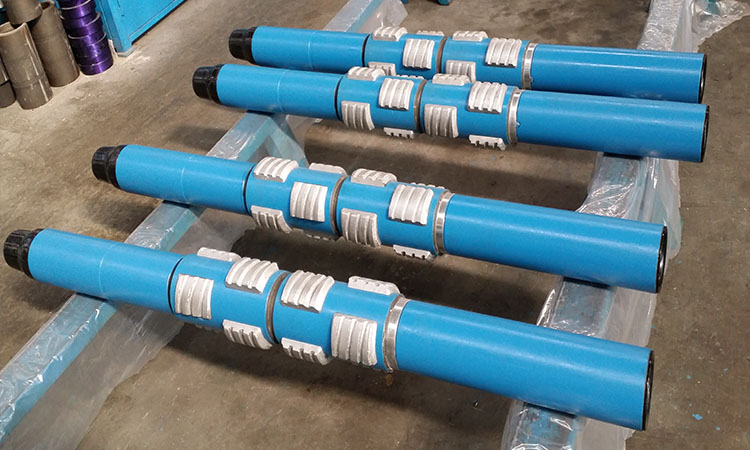

Sino Mechanical's drill collars include smooth drill collars, helical drill collars, and drill collars with slip grooves, elevator grooves and wear rings.

Features of Drill Collars

1. First class equipment could guarantee the whole process flow and the clave process be more efficient like heat treating and friction welding.

2. Advanced and strict inspection instruments could guarantee the high quality drill collars with a more stable performance.

3. The wall thickness of the drill collar is large (generally 38~53mm, equivalent to 4~6 times the wall thickness of the drill pipe), with greater gravity and rigidity.

4. Sino Mechanical's drill collars are made of rolled or forged AISI4145H chrome-molybdenum alloy steel, which effectively controls the chemical composition and trace element content.

5. The heat treatment of Sino Mechanical's drill collars is quenched and tempered by unique power frequency induction heating. During this process, the steel piece is continuously rotated and advanced to be heated evenly. In the process of quenching and hardening, the annular inner and outer spray water cooling method is especially used to obtain uniform and high strength. After the drill collar material has been heat-treated throughout the length, it can ensure a Brinell hardness of 285~341 at a point 1” below the surface of the pipe body.

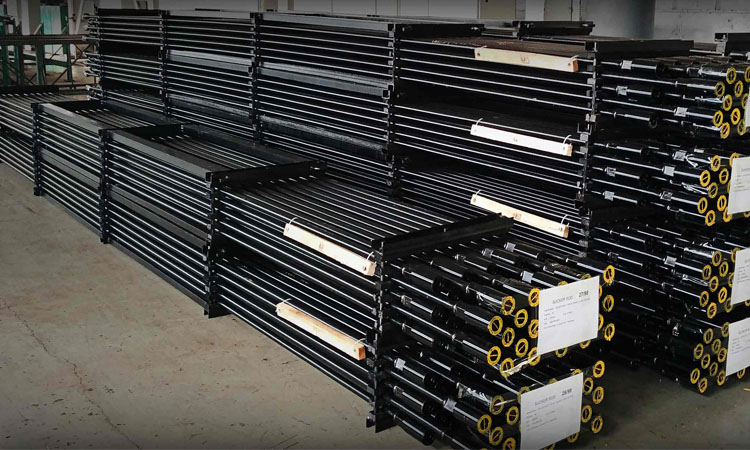

6. Sino Mechanical can provide drill collar in various lengths from 5 feet to 32 feet long, and the outer diameter ranges from 3-1/8” to 11”.

7. Pressed steel thread protectors are supplied to all drill collar that are equipped with standard connections.

8. Widely used in oil, gas, HDD and geothermal field.

9. Drill collar are uniquely marked with steel letters on the product pipe body during the whole process from receiving qualified raw materials to production, delivery and installation, and its traceability has been maintained.

10. All series of drill collars are fully inspected one by one to meet the requirements of API standards and our internal technical conditions. The inspection includes not only dimensional inspection, but also destructive tests on the mechanical properties of the drill collars and the entire pipe body. Ultrasonic testing performed.

Applications of Drill Collars

Drill Collars are one of the most important elements of drill stem. It can provide drilling pressure to the bit and improve drill stem rigid.

Effectively control the trace element of the material which was selected with high quality and unique method. Adopt special intermediate frequency heat treatment method and advanced ultrasonic and magnetic particle inspection method and holding higher mechanical property.

1. Add drilling pressure to the drill bit.

2. Ensure the necessary strength under compression conditions.

3. Reduce the vibration, swing, and jump of the drill bit, so that the drill bit works smoothly.

4. Control well deviation.

Maintenance of Drill Collars

1. After the drill collar stops drilling, it is necessary to clean and inspect the threaded part in time, and repair and protect it if necessary. Although there is a dense and sufficient phosphating protective layer on the surface of the threaded connection, the phosphating layer will be damaged by wear during use. When the phosphating protective layer is found to be damaged, the phosphating protective layer should be applied in time to minimize the wear of the thread.

2. For the handling and transportation of drill collar, reasonable and correct methods must be adopted, and wire protection caps must be worn at both ends of the drill collar to prevent the product from falling, bumping, and damage.

Types of drill collars:

According to the shape and material, drill collars are divided into three types:

1. Integral drill collar

The integral drill collar is a smooth thick-walled round tube with connecting threads processed at both ends.

2. Spiral drill collar

The role of the helical drill collar is to reduce sticking and sticking. Three right-handed helical grooves are processed on the outer cylinder of the round drill collar. There is a section of 305-560mm in the external thread joint part and 475-mm in the internal thread end joint part. The weight of the 610mm ungrooved round drill collar section is 4% less than that of the same size round drill collar. Spiral drill collars are not included in the API standard, but many foreign manufacturers have produced them. Domestic drill collars have also been officially put into production, and their specifications and dimensions are the same as those of foreign products.

3. Non-magnetic drill collar

The material is forged through strict chemical composition analysis. The material has been tested for mechanical properties to ensure that the hardness, toughness, impact value and corrosion resistance meet the standards, and it has good low magnetic permeability and good machinability. The structure of non-magnetic drill collars is the same as that of ordinary drill collars, but the chemical composition and mechanical properties are different from ordinary drill collars. Non-magnetic drill collars are drilling tools with special functions in directional well engineering. When the magnetic inclinometer is used in directional wells to measure the inclination angle and azimuth of the borehole, in order to prevent the compass from being affected by the magnetic field of the drill string, a certain length of non-magnetic drill collar must be equipped in the drill string so that the magnetic inclinometer is located in the non-magnetic The inclination measurement must be carried out at a suitable position in the drill collar, otherwise the correct measurement result cannot be obtained.

Price of Drill Collars

The Drill Collars Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Drill Collars. If you are looking for Drill Collars, please kindly contact us to get the latest Drill Collars price.

Drill Collars Supplier

Sino Mechanical, as a Drill Collars manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Drill Collars. We are global Drill Collars supplier. We offer a wide range of drilling equipment and have Drill Collars for sale. We also provide OEM services. We design, manufacture, and sell Drill Collars for your drilling applications. If you want to know latest Drill Collars price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Drill Collars

Size (in) | O.D (mm) | I.D. (in) | Code | Thread | Length (mm) | Weight (kg) |

3 1/8 | 79.4 | 1-1/4 | NC23-31 | NC23 | 9140 | 298 |

3 1/2 | 88.9 | 1-1/2 | NC26-35 | NC26 | 9140 | 364 |

4 1/8 | 104.8 | 2 | NC31-41 | NC31 | 9140/9450 | 474/490 |

4 3/4 | 120.6 | 2 | NC35-47 | NC35 | 9140/9450 | 674/697 |

5 | 127 | 2-1/4 | NC38-50 | NC38 | 9140/9450 | 725/749 |

6 | 152.4 | 2-1/4 | NC44-60 | NC44 | 9140/9450 | 1125/1163 |

6 | 152.4 | 2-13/16 | NC44-60 | NC44 | 9140/9450 | 1022/1056 |

6 1/4 | 158.8 | 2-1/4 | NC44-62 | NC44 | 9140/9450 | 1237/1279 |

6 1/4 | 158.8 | 2-13/16 | NC46-62 | NC44 | 9140/9450 | 1134/1172 |

6 1/2 | 165.1 | 2-1/4 | NC46-65 | NC46 | 9140/9450 | 1352/1398 |

6 1/2 | 165.1 | 2-13/16 | NC46-65 | NC50 | 9140/9450 | 1249/1291 |

6 3/4 | 171.4 | 2-1/4 | NC46-67 | NC46 | 9140/9450 | 1471/1521 |

7 | 177.8 | 2-1/4 | NC50-70 | NC50 | 9140/9450 | 1597/1651 |

7 | 177.8 | 2-13/16 | NC50-70 | NC50 | 9140/9450 | 1494/1545 |

7 1/4 | 184.2 | 2-13/16 | NC50-72 | NC50 | 9140/9450 | 1625/1680 |

7 3/4 | 196.8 | 2-13/16 | NC56-77 | NC56 | 9140/9450 | 1895/1960 |

8 | 203.2 | 2-13/16 | NC56-80 | NC56 or 6- 5/8REG | 9140/9450 | 2040/2109 |

8 1/4 | 209.6 | 2-13/16 | 6-5/8REG | 6-5/8REG | 9140/9450 | 2188/2263 |

9 | 228.6 | 2-13/16 | NC61-90 | NC61 | 9140/9450 | 2658/2748 |

9 1/2 | 241.3 | 2-13/16 | 7-5/8REG | 7-5/8REG | 9140/9450 | 2954/3054 |

9 3/4 | 247.6 | 3 | NC70-97 | NC70 | 9140/9450 | 3127/3234 |

10 | 254 | 3 | NC70-100 | NC70 | 9140/9450 | 3308/3421 |

11 | 279.4 | 3 | 8-5/8REG | 8-5/8REG | 9140/9450 | 4072/4210 |

Mechanical properties: <7 inch Drill Collar: Yield Strength≥758MPa, Tensile Strength≥965MPa, Four times elongation ≥13%, Impact energy Ak≥54J (Single impact work≥47J, Average≥54J), Hardness range: 285HB~341HB ≥7inch Drill Collar: Yield Strength≥689MPa, Tensile Strength≥931MPa, Four times elongation≥13%, Impact energy Ak≥54J (Single impact work≥47J, Average≥54J), Hardness range 285HB~341HB | ||||||

Drill collar can be customized as per customer’s design. | ||||||