Description

Overview of Downhole Motors

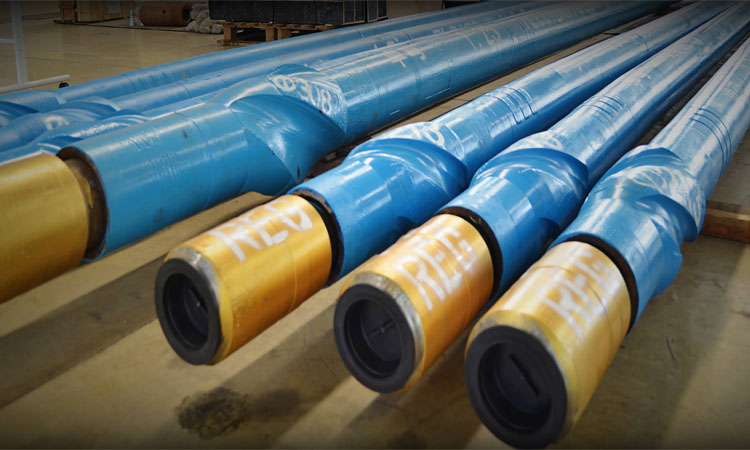

Downhole motor is to convert the high pressure fluid power of mud into mechanical energy for bit rotation. It is widely used in oil field and mine directional well and horizontal well, cluster Wells and vertical Wells, drilling, deflecting, adjusting azimuth, coring, reaming, side tracking and work-over treatment, and also applied in some special operations as compound drilling and traversing, etc.

Downhole motor refers to the bottom hole drilling tool that can convert the energy of drilling fluid into drilling rock breaking power, such as turbo drilling tool, single Downhole Motors, electric drilling tool, etc. Due to the downhole motor ( Bottom hole motor) has a high speed, which can significantly increase the mechanical drilling speed, especially when used in conjunction with the PDC bit, the drilling speed will be greatly improved.

Downhole motors are different from the traditional rotary table in terms of improving the mechanical penetration rate, increasing the footage of a single drill bit, reducing the drilling cost per meter, realizing the directional control of the well trajectory, fast and accurate targeting, and ensuring the quality of the well and drilling safety. Compared with drilling, it has great advantages.

Sino Mechanical downhole motor can work around 200 hours for one running in general. The working life of the power section has reached more than 1,000 hours. A hydraulically driven downhole motor that known as positive displacement motor or pdm is used to rotate the bit, independent of drill string rotation.

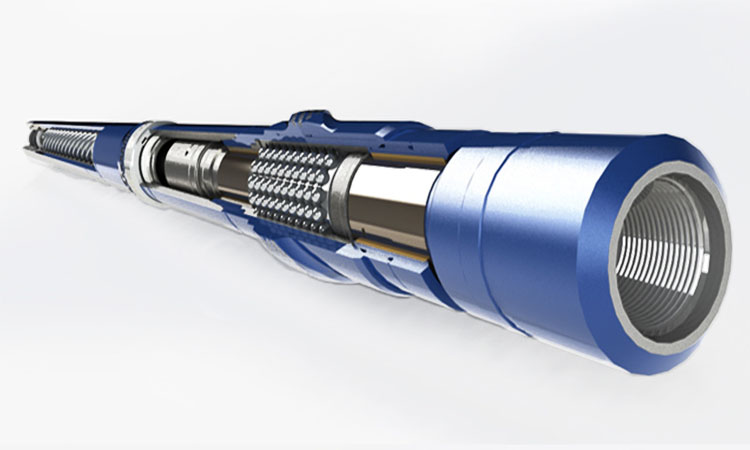

Downhole Motors consist of

Downhole motors are mainly composed of four assemblies: Dump Assembly, hydraulic motor, cardan shaft and transmission shaft. The screw motor is the main component of the drilling tool. When the drill mud flows through the motor, the cavities between the stator and rotor are filled. The rotor then performs an eccentric rotational motion that is forwarded to the drill bit as drive power.

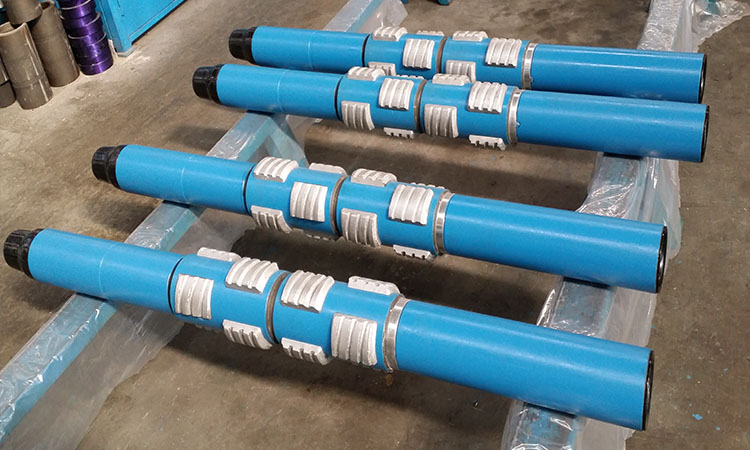

Features of Downhole Motors

Sino Mechanical has Downhole Motors of all sizes and configurations. Sino Mechanical can also provide the market with specially designed products according to the individual needs of users for parameters such as torque, displacement, and well temperature.

1. Various sizes of down-hole motors of high speed, medium speed and low speed.

2. Wide output range of speed, torque and high frequency.

3. Fix bend and adjustable bend are available.

4. Saturated saltwater mud resistant down-hole motor, high temperature resistant down-hole motor and oil-based mud resistant.

5. Equal wall thickness

The constant wall thickness Downhole Motors is designed by rationally changing the shape of the stator shell, and the stator rubber layer is designed as a thin and uniform constant wall thickness motor stator. This kind of Downhole Motors has the characteristics of short length, high power, high pressure drop, low speed, high heat dissipation efficiency, uniform thermal expansion, wider application range, more optimized structure, and lighter overall weight. Especially in ultra-deep wells, horizontal wells, and high-temperature wells, it prolongs the life of Downhole Motors and improves drilling efficiency.

6. High temperature resistance, oil-based mud resistance

This type of Downhole Motors is suitable for high temperature and high oil content mud system. The specially formulated stator rubber can achieve high retention rate of physical properties such as strength and tear strength under 180°C and high oil content conditions; reasonable interference fit, so that The high-oil-resistant rubber achieves good results under the conditions of high temperature and high oil-based mud.

7. Corrosion resistance

The rotor is sprayed with anti-corrosion to form a special coating, which is more resistant to corrosion, erosion and grinding, so that the Downhole Motors can work for a long time in the corrosive mud environment.

8. Air drilling

Gas drilling can well protect oil and gas reservoirs, increase the rate of penetration, significantly shorten the drilling cycle, and prevent well leakage and well collapse. It has been gradually popularized and applied in the industry. Air drilling Downhole Motors are driven by compressible fluids such as gas and foam as the medium to provide power for the downhole and drive the drill bit to break rock. Air drilling Downhole Motors have higher technical requirements in terms of composition structure, motor stator linear design and operation specifications.

Applications of Downhole Motors

Downhole Motors can be used in conjunction with roller cone bits, diamond bits and other special bits for drilling operations in vertical wells, directional wells and horizontal wells.

With the rapid development of coiled tubing drilling technology, downhole Downhole Motors as drilling/workover tools are also developing in the direction of miniaturization. The application of small Downhole Motors for coiled tubing operations in tubing workover operations, window sidetracking, micro-hole drilling and re-drilling of old wells has also been paid more and more attention and researched in China. In coiled tubing operations at home and abroad, because coiled tubing cannot rotate, drilling and workover operations need to rely on downhole motors to provide power. Small Downhole Motors are one of the best supporting tools for coiled tubing drilling and workover operations, and have been used in many operations, such as well washing, sand washing, fishing, etc.

Different Types of Downhole Motors Available

At present, in addition to the more common straight Downhole Motors, the following types of Downhole Motors can also be provided:

1. Bending Downhole Motors: On the cardan shaft shell of the Downhole Motors, a structural bending angle is added to meet the needs of different curvatures. Divided into single curved shell and double curved shell.

2. Angle-adjustable Downhole Motors: In order to improve the requirements for different build-up rates of curved Downhole Motors, the bending angle of Downhole Motors can be adjusted on the well as required.

3. Extended Downhole Motors: On the basis of ordinary Downhole Motors, the number of motor stages is increased to increase the torque of the Downhole Motors, so as to achieve the effect of the drill bit breaking rock quickly.

4. Hollow Downhole Motors: In order to meet the needs of large displacement cuttings during drilling, the hollow rotor with carbide nozzles of different sizes can be used to increase the input flow rate and increase the water drive of the drill bit.

5. High deflection Downhole Motors: structural design, the length of the whole machine is shorter, the camber is closer to the drill bit, and the deflection rate is as high as >1o/m.

6. Saturated salt water slurry resistant Downhole Motors: In order to make the Downhole Motors work for a long time in the saturated salt water slurry environment, the drilling tool coating is used.

7. High-temperature Downhole Motors: In order to improve the capacity of Downhole Motors stator rubber to meet the needs of drilling in areas with high geothermal gradients, deep wells, and ultra-deep wells under high temperature conditions, the motor stator is made of rubber, which can increase the high temperature resistance of the motor to Above 150°C.

8. Sealed transmission shaft Downhole Motors: change the ordinary mud-lubricated transmission shaft to an oil-lubricated sealed transmission shaft, and change the thrust bearing and radial shaft Prolong the service life of the Downhole Motors as a whole in the unaffected working environment.

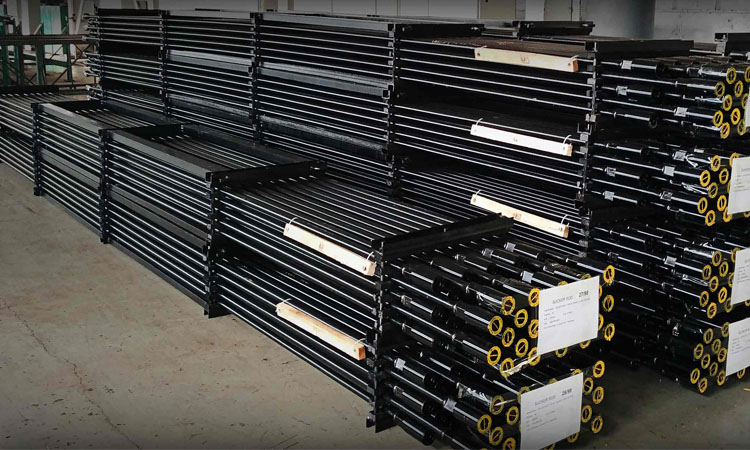

Price of Downhole Motors

The Downhole Motors Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Downhole Motors. If you are looking for Downhole Motors, please kindly contact us to get the latest Downhole Motors price.

Downhole Motors Supplier

Sino Mechanical, as a Downhole Motors manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Downhole Motors. We are global Downhole Motors supplier. We offer a wide range of drilling equipment and have Downhole Motors for sale. We also provide OEM services. We design, manufacture, and sell Downhole Motors for your drilling applications. If you want to know latest Downhole Motors price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Downhole Motors

| Model Size | Lobes | Stages | Tube OD | Flow Rate Range | Speed Range | Rotation | Hole Size Range | Thread Connections | ||

| inch | mm | in(mm) | gpm(lpm) | rpm | rev/gal(rev/liter) | in | Box-Up | Box-Down | ||

| 1-11/16 | 43 | 3:4 | 3.4 | 1.693(43) | 3-8(12-30) | 94-234 | 29.59(7.816) | 1-7/8 - 3 | M27×2 | M27×2 |

| 1-11/16 | 43 | 4:5 | 3.4 | 1.693(43) | 3-8(12-30) | 77-193 | 24.39(6.442) | 1-7/8 - 3 | M27×2 | M27×2 |

| 1-11/16 | 43 | 4:5 | 4.0 | 1.693(43) | 3-8(12-30) | 93-232 | 29.26(7.73) | 1-7/8 - 3 | M27×2 | M27×2 |

| 1-11/16 | 43 | 4:5 | 4.1 | 1.693(43) | 14-26(52-100) | 251-483 | 18.29(4.831) | 1-7/8 - 3 | M27×2 | M27×2 |

| 1-11/16 | 43 | 4:5 | 5.5 | 1.693(43) | 14-26(52-100) | 335-644 | 24.39(6.442) | 1-7/8 - 3 | M27×2 | M27×2 |

| 1-11/16 | 43 | 5:6 | 4.0 | 1.693(43) | 21-40(80-150) | 307-576 | 14.52(3.837) | 1-7/8 - 3 | M27×2 | M27×2 |

| 1-11/16 | 43 | 5:6 | 5.6 | 1.693(43) | 21-40(80-150) | 291-545 | 13.75(3.632) | 1-7/8 - 3 | M27×2 | M27×2 |

| 2-1/8 | 54 | 4:5 | 4.8 | 2.126(54) | 29-66(110-250) | 294-668 | 10.11(2.672) | 2-3/8 - 3-1/2 | M33×2 | M33×2 |

| 2-1/8 | 54 | 4:5 | 4.8 | 2.126(54) | 29-66(110-250) | 305-693 | 10.49(2.77) | 2-3/8 - 3-1/2 | M33×2 | M33×2 |

| 2-1/8 | 54 | 5:6 | 3.5 | 2.126(54) | 29-66(110-250) | 226-513 | 7.77(2.053) | 2-3/8 - 3-1/2 | M33×2 | M33×2 |

| 2-1/8 | 54 | 5:6 | 3.5 | 2.126(54) | 29-66(110-250) | 234-532 | 8.06(2.129) | 2-3/8 - 3-1/2 | M33×2 | M33×2 |

| 2-3/8 | 60 | 5:6 | 5.0 | 2.362(60) | 29-66(110-250) | 239-543 | 8.22(2.171) | 2-7/8 - 3-9/16 | 1-1/2 TBG | 1-1/2 TBG |

| 2-1/2 | 65 | 4:5 | 3.6 | 2.559(65) | 29-66(110-250) | 205-466 | 7.06(1.865) | 2-7/8 - 3-9/16 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 4:5 | 3.2 | 2.874(73) | 29-90(110-340) | 136-419 | 4.66(1.232) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 4:5 | 3.5 | 2.874(73) | 29-90(110-340) | 129-398 | 4.43(1.171) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 4:5 | 3.9 | 2.874(73) | 29-90(110-340) | 144-444 | 4.94(1.306) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 4:5 | 4.1 | 2.874(73) | 29-90(110-340) | 147-453 | 5.05(1.333) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 4:5 | 4.3 | 2.874(73) | 29-90(110-340) | 136-419 | 4.66(1.232) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 5:6 | 2.9 | 2.874(73) | 29-90(110-340) | 78-242 | 2.7(0.712) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 5:6 | 4.1 | 2.874(73) | 29-90(110-340) | 126-388 | 4.32(1.141) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 5:6 | 2.6 | 2.874(73) | 61-119(230-450) | 90-176 | 1.48(0.391) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 5:6 | 2.6 | 2.874(73) | 61-119(230-450) | 78-153 | 1.29(0.341) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 5:6 | 5.0 | 2.874(73) | 90-169(340-640) | 254-478 | 2.83(0.747) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 6:7 | 3.1 | 2.874(73) | 61-119(230-450) | 151-295 | 2.48(0.656) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 7:8 | 2.9 | 2.874(73) | 61-119(230-450) | 141-275 | 2.31(0.611) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 7:8 | 3.1 | 2.874(73) | 61-119(230-450) | 176-344 | 2.9(0.765) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 7:8 | 3.1 | 2.874(73) | 61-119(230-450) | 142-278 | 2.34(0.618) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 7:8 | 4.4 | 2.874(73) | 61-119(230-450) | 244-477 | 4.02(1.061) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 2-7/8 | 73 | 7:8 | 4.4 | 2.874(73) | 61-119(230-450) | 252-494 | 4.15(1.097) | 3-1/8 - 4-3/8 | 1-1/2 TBG | 1-1/2 TBG |

| 3-1/8 | 80 | 5:6 | 3.0 | 3.15(80) | 79-140(300-530) | 191-337 | 2.4(0.635) | 3-3/4 - 4-3/4 | 2-3/8 REG | 2-3/8 REG |

| 3-1/8 | 80 | 7:8 | 6.3 | 3.15(80) | 79-140(300-530) | 151-266 | 1.9(0.502) | 3-3/4 - 4-3/4 | 2-3/8 REG | 2-3/8 REG |

| 3-1/2 | 89 | 5:6 | 6.7 | 3.504(89) | 29-111(110-420) | 53-202 | 1.82(0.482) | 4-1/2 - 5-7/8 | 2-3/8 REG | 2-3/8 REG |

| 3-1/2 | 89 | 7:8 | 3.9 | 3.504(89) | 95-143(360-540) | 126-189 | 1.32(0.35) | 4-1/2 - 5-7/8 | 2-3/8 REG | 2-3/8 REG |

| 3-1/2 | 89 | 7:8 | 4.2 | 3.504(89) | 79-161(300-610) | 79-160 | 1(0.263) | 4-1/2 - 5-7/8 | 2-3/8 REG | 2-3/8 REG |

| 3-1/2 | 89 | 7:8 | 4.6 | 3.504(89) | 53-74(200-280) | 145-204 | 2.75(0.727) | 4-1/2 - 5-7/8 | 2-3/8 REG | 2-3/8 REG |

| 3-1/2 | 89 | 7:8 | 5.7 | 3.504(89) | 53-74(200-280) | 130-182 | 2.46(0.649) | 4-1/2 - 5-7/8 | 2-3/8 REG | 2-3/8 REG |

| 3-1/2 | 89 | 7:8 | 6.5 | 3.504(89) | 53-74(200-280) | 166-232 | 3.14(0.83) | 4-1/2 - 5-7/8 | 2-3/8 REG | 2-3/8 REG |

| 3-3/4 | 95 | 2:3 | 10.1 | 3.74(95) | 79-161(300-610) | 745-1515 | 9.4(2.483) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 4:5 | 5.7 | 3.74(95) | 79-161(300-610) | 188-383 | 2.38(0.628) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 5:6 | 3.1 | 3.74(95) | 79-161(300-610) | 123-251 | 1.56(0.411) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 5:6 | 4.3 | 3.74(95) | 79-161(300-610) | 123-251 | 1.56(0.411) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 5:6 | 6.6 | 3.74(95) | 79-161(300-610) | 123-251 | 1.56(0.411) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 7:8 | 3.1 | 3.74(95) | 79-161(300-610) | 104-211 | 1.31(0.346) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 7:8 | 4.3 | 3.74(95) | 79-161(300-610) | 104-211 | 1.31(0.346) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 3-3/4 | 95 | 7:8 | 4.3 | 3.74(95) | 79-161(300-610) | 107-218 | 1.36(0.358) | 4-5/8 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 4-1/32 | 102 | 5:6 | 3.2 | 4.016(102) | 79-161(300-610) | 146-296 | 1.84(0.486) | 4-3/4 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 4-1/8 | 106 | 7:8 | 5.9 | 4.173(106) | 79-190(300-720) | 96-230 | 1.21(0.32) | 4-3/4 - 5-7/8 | 2-7/8 REG | 2-7/8 REG |

| 4-3/4 | 120 | 4:5 | 4.7 | 4.724(120) | 100-251(380-950) | 96-239 | 0.95(0.252) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 4:5 | 5.5 | 4.724(120) | 100-251(380-950) | 149-373 | 1.49(0.393) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 5:6 | 4.2 | 4.724(120) | 100-251(380-950) | 81-202 | 0.81(0.213) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 5:6 | 4.2 | 4.724(120) | 100-251(380-950) | 72-181 | 0.72(0.19) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 5:6 | 5.2 | 4.724(120) | 100-251(380-950) | 81-202 | 0.81(0.213) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 5:6 | 5.5 | 4.724(120) | 100-251(380-950) | 94-236 | 0.94(0.248) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 7:8 | 3.8 | 4.724(120) | 151-349(570-1320) | 77-178 | 0.51(0.135) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 7:8 | 3.8 | 4.724(120) | 151-349(570-1320) | 77-178 | 0.51(0.135) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 7:8 | 4.0 | 4.724(120) | 151-349(570-1320) | 97-226 | 0.65(0.171) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 7:8 | 4.3 | 4.724(120) | 151-349(570-1320) | 63-145 | 0.42(0.11) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 4-3/4 | 120 | 7:8 | 6.3 | 4.724(120) | 151-349(570-1320) | 91-210 | 0.6(0.159) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 2:3 | 6.9 | 5(127) | 100-251(380-950) | 162-406 | 1.62(0.427) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 2:3 | 11.4 | 5(127) | 100-251(380-950) | 382-955 | 3.8(1.005) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 2:3 | 11.4 | 5(127) | 100-251(380-950) | 325-813 | 3.24(0.856) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 3:4 | 3.8 | 5(127) | 100-251(380-950) | 111-276 | 1.1(0.291) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 7:8 | 2.7 | 5(127) | 151-349(570-1320) | 64-149 | 0.43(0.113) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 7:8 | 2.8 | 5(127) | 151-349(570-1320) | 56-131 | 0.37(0.099) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 7:8 | 3.3 | 5(127) | 151-349(570-1320) | 64-149 | 0.43(0.113) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5 | 127 | 7:8 | 3.5 | 5(127) | 151-349(570-1320) | 56-131 | 0.37(0.099) | 5-7/8 - 7-7/8 | 3-1/2 REG | 3-1/2 REG |

| 5-3/8 | 135 | 5:6 | 4.5 | 5.315(135) | 211-423(800-1600) | 123-246 | 0.58(0.154) | 6-3/4 - 8-3/4 | 4-1/2 REG | 4-1/2 REG |

| 5-3/8 | 135 | 7:8 | 2.9 | 5.315(135) | 211-423(800-1600) | 72-144 | 0.34(0.09) | 6-3/4 - 8-3/4 | 4-1/2 REG | 4-1/2 REG |

| 5-1/2 | 140 | 5:6 | 5.5 | 5.512(140) | 317-396(1200-1500) | 152-191 | 0.48(0.127) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 5-1/2 | 140 | 7:8 | 3.8 | 5.512(140) | 317-396(1200-1500) | 146-183 | 0.46(0.122) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 5-1/2 | 140 | 7:8 | 4.6 | 5.512(140) | 317-396(1200-1500) | 100-125 | 0.31(0.083) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 5-1/2 | 140 | 7:8 | 5.6 | 5.512(140) | 317-396(1200-1500) | 120-150 | 0.38(0.1) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 6-1/2 | 165 | 1:2 | 1.1 | 6.496(165) | 301-600(1140-2270) | 295-588 | 0.98(0.259) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 5:6 | 5.1 | 6.496(165) | 301-600(1140-2270) | 132-263 | 0.44(0.116) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 7:8 | 3.2 | 6.496(165) | 301-600(1140-2270) | 49-98 | 0.16(0.043) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 7:8 | 4.7 | 6.496(165) | 301-600(1140-2270) | 73-145 | 0.24(0.064) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 7:8 | 4.7 | 6.496(165) | 301-600(1140-2270) | 79-157 | 0.26(0.069) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 7:8 | 4.7 | 6.772(172) | 301-600(1140-2270) | 95-188 | 0.31(0.083) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 7:8 | 5.6 | 6.496(165) | 301-600(1140-2270) | 88-175 | 0.29(0.077) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-1/2 | 165 | 7:8 | 5.6 | 6.496(165) | 301-600(1140-2270) | 95-188 | 0.31(0.083) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 2:3 | 9.4 | 6.772(172) | 301-600(1140-2270) | 380-756 | 1.26(0.333) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 2:3 | 11.7 | 6.772(172) | 301-600(1140-2270) | 589-1174 | 1.96(0.517) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 4:5 | 6.7 | 6.772(172) | 301-600(1140-2270) | 138-275 | 0.46(0.121) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 4:5 | 10.3 | 6.772(172) | 301-600(1140-2270) | 182-363 | 0.61(0.16) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 5:6 | 5.6 | 6.772(172) | 301-600(1140-2270) | 104-207 | 0.34(0.091) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 5:6 | 6.2 | 6.772(172) | 301-600(1140-2270) | 112-222 | 0.37(0.098) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 5:6 | 6.2 | 6.772(172) | 301-600(1140-2270) | 114-227 | 0.38(0.1) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 5:6 | 6.4 | 6.772(172) | 301-600(1140-2270) | 121-241 | 0.4(0.106) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 5:6 | 7.1 | 6.772(172) | 301-600(1140-2270) | 112-222 | 0.37(0.098) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 3.0 | 6.772(172) | 301-600(1140-2270) | 83-166 | 0.28(0.073) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 3.2 | 6.772(172) | 301-600(1140-2270) | 42-84 | 0.14(0.037) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.0 | 6.772(172) | 301-600(1140-2270) | 79-157 | 0.26(0.069) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.0 | 6.772(172) | 301-600(1140-2270) | 65-129 | 0.22(0.057) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.0 | 6.772(172) | 301-600(1140-2270) | 57-114 | 0.19(0.05) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.3 | 6.772(172) | 301-600(1140-2270) | 73-145 | 0.24(0.064) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.3 | 6.772(172) | 301-600(1140-2270) | 79-157 | 0.26(0.069) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.7 | 6.772(172) | 301-600(1140-2270) | 73-145 | 0.24(0.064) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.7 | 6.772(172) | 301-600(1140-2270) | 95-188 | 0.31(0.083) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.7 | 6.772(172) | 301-600(1140-2270) | 95-188 | 0.31(0.083) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 4.9 | 6.772(172) | 301-600(1140-2270) | 65-129 | 0.22(0.057) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.0 | 6.772(172) | 301-600(1140-2270) | 83-166 | 0.28(0.073) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.0 | 6.772(172) | 301-600(1140-2270) | 83-166 | 0.28(0.073) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.0 | 6.772(172) | 301-600(1140-2270) | 74-148 | 0.25(0.065) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.1 | 6.772(172) | 301-600(1140-2270) | 88-175 | 0.29(0.077) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.1 | 6.772(172) | 301-600(1140-2270) | 95-188 | 0.31(0.083) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.1 | 6.772(172) | 301-600(1140-2270) | 71-141 | 0.23(0.062) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.5 | 6.772(172) | 301-600(1140-2270) | 83-166 | 0.28(0.073) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.5 | 6.772(172) | 301-600(1140-2270) | 83-166 | 0.28(0.073) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 5.6 | 6.772(172) | 301-600(1140-2270) | 88-175 | 0.29(0.077) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 6.3 | 6.772(172) | 301-600(1140-2270) | 83-166 | 0.28(0.073) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 7:8 | 6.4 | 6.772(172) | 301-600(1140-2270) | 88-175 | 0.29(0.077) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 6-3/4 | 172 | 9:10 | 8.3 | 6.772(172) | 301-600(1140-2270) | 79-157 | 0.26(0.069) | 8-3/8 - 9-7/8 | 4-1/2 REG | 4-1/2 REG |

| 7-1/4 | 185 | 5:6 | 5.6 | 7.283(185) | 301-600(1140-2270) | 90-179 | 0.3(0.079) | 8-3/4 - 9-7/8 | 5-1/2 REG | 6-5/8 REG |

| 7-1/4 | 185 | 6:7 | 3.8 | 7.283(185) | 301-600(1140-2270) | 79-157 | 0.26(0.069) | 8-3/4 - 9-7/8 | 5-1/2 REG | 6-5/8 REG |

| 7-1/4 | 185 | 6:7 | 4.8 | 7.283(185) | 301-600(1140-2270) | 60-120 | 0.2(0.053) | 8-3/4 - 9-7/8 | 5-1/2 REG | 6-5/8 REG |

| 7-1/4 | 185 | 7:8 | 3.2 | 7.283(185) | 301-600(1140-2270) | 42-84 | 0.14(0.037) | 8-3/4 - 9-7/8 | 5-1/2 REG | 6-5/8 REG |

| 7-1/4 | 185 | 7:8 | 5.6 | 7.283(185) | 301-600(1140-2270) | 74-148 | 0.25(0.065) | 8-3/4 - 9-7/8 | 5-1/2 REG | 6-5/8 REG |

| 7-1/4 | 185 | 7:8 | 4.9 | 7.283(185) | 301-600(1140-2270) | 65-129 | 0.22(0.057) | 8-3/4 - 9-7/8 | 5-1/2 REG | 6-5/8 REG |

| 7-3/4 | 197 | 2:3 | 6.9 | 7.756(197) | 399-901(1510-3410) | 432-975 | 1.08(0.286) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 7-3/4 | 197 | 5:6 | 5.6 | 7.756(197) | 399-901(1510-3410) | 107-242 | 0.27(0.071) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 7-3/4 | 197 | 6:7 | 4.8 | 7.756(197) | 399-901(1510-3410) | 72-164 | 0.18(0.048) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 7-3/4 | 197 | 6:7 | 4.8 | 7.756(197) | 634-793(2400-3000) | 115-144 | 0.18(0.048) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 4:5 | 5.6 | 7.992(203) | 399-901(1510-3410) | 106-239 | 0.26(0.07) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 4:5 | 6.1 | 7.992(203) | 399-901(1510-3410) | 97-218 | 0.24(0.064) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 5:6 | 3.0 | 7.992(203) | 399-901(1510-3410) | 92-208 | 0.23(0.061) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 5:6 | 5.6 | 7.992(203) | 399-901(1510-3410) | 92-208 | 0.23(0.061) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 6:7 | 4.8 | 7.992(203) | 399-901(1510-3410) | 69-157 | 0.17(0.046) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 7:8 | 4.1 | 7.992(203) | 399-901(1510-3410) | 62-140 | 0.16(0.041) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 7:8 | 3.8 | 7.992(203) | 399-901(1510-3410) | 62-140 | 0.16(0.041) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 7:8 | 4.2 | 7.992(203) | 399-901(1510-3410) | 56-126 | 0.14(0.037) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8 | 203 | 7:8 | 4.2 | 7.992(203) | 399-901(1510-3410) | 56-126 | 0.14(0.037) | 9-7/8 - 12-1/4 | 6-5/8 REG | 6-5/8 REG |

| 8-1/2 | 216 | 5:6 | 5.6 | 8.504(216) | 528-1057(2000-4000) | 104-208 | 0.2(0.052) | 12-1/4 - 15-1/2 | 6-5/8 REG | 6-5/8 REG |

| 8-1/2 | 216 | 6:7 | 4.8 | 8.504(216) | 449-1001(1700-3790) | 63-140 | 0.14(0.037) | 12-1/4 - 15-1/2 | 6-5/8 REG | 6-5/8 REG |

| 8-1/2 | 216 | 6:7 | 4.8 | 8.504(216) | 399-901(1510-3410) | 60-136 | 0.15(0.04) | 12-1/4 - 15-1/2 | 6-5/8 REG | 6-5/8 REG |

| 8-1/2 | 216 | 7:8 | 4.2 | 8.504(216) | 399-901(1510-3410) | 51-116 | 0.13(0.034) | 12-1/4 - 15-1/2 | 6-5/8 REG | 6-5/8 REG |

| 9 | 228 | 5:6 | 4.2 | 8.976(228) | 600-1199(2270-4540) | 77-154 | 0.13(0.034) | 12-1/4 - 15-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9 | 228 | 5:6 | 5.6 | 8.976(228) | 600-1199(2270-4540) | 107-213 | 0.18(0.047) | 12-1/4 - 15-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9 | 228 | 6:7 | 4.8 | 8.976(228) | 600-1199(2270-4540) | 79-159 | 0.13(0.035) | 12-1/4 - 15-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9 | 228 | 7:8 | 4.2 | 8.976(228) | 600-1199(2270-4540) | 61-123 | 0.1(0.027) | 12-1/4 - 15-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9 | 228 | 7:8 | 4.2 | 8.976(228) | 600-1199(2270-4540) | 70-141 | 0.12(0.031) | 12-1/4 - 15-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 5:6 | 4.2 | 9.606(244) | 600-1199(2270-4540) | 77-154 | 0.13(0.034) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 6:7 | 4.8 | 9.606(244) | 600-1199(2270-4540) | 79-159 | 0.13(0.035) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 7:8 | 4.2 | 9.606(244) | 600-1199(2270-4540) | 61-123 | 0.1(0.027) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 7:8 | 4.3 | 9.606(244) | 600-1199(2270-4540) | 64-127 | 0.11(0.028) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 7:8 | 4.9 | 9.606(244) | 600-1199(2270-4540) | 75-150 | 0.12(0.033) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 7:8 | 6.1 | 9.606(244) | 600-1199(2270-4540) | 75-150 | 0.12(0.033) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 9-5/8 | 244 | 9:10 | 7.2 | 9.606(244) | 600-1199(2270-4540) | 73-145 | 0.12(0.032) | 12-1/4 - 17-1/2 | 6-5/8 REG | 7-5/8 REG |

| 11-1/4 | 286 | 4:5 | 5.0 | 11.26(286) | 600-1199(2270-4540) | 73-145 | 0.12(0.032) | 14-3/4 - 26 | 7-5/8 REG | 7-5/8 REG |

| 11-1/4 | 286 | 7:8 | 5.8 | 11.26(286) | 600-1199(2270-4540) | 59-118 | 0.1(0.026) | 14-3/4 - 26 | 7-5/8 REG | 7-5/8 REG |

| 11-1/4 | 286 | 9:10 | 4.2 | 11.26(286) | 600-1199(2270-4540) | 39-77 | 0.06(0.017) | 14-3/4 - 26 | 7-5/8 REG | 7-5/8 REG |

| 11-1/4 | 286 | 13:14 | 4.0 | 11.26(286) | 600-1199(2270-4540) | 27-54 | 0.05(0.012) | 14-3/4 - 26 | 7-5/8 REG | 7-5/8 REG |

| 13-3/8 | 340 | 9:10 | 3.4 | 13.386(340) | 399-901(1510-3410) | 14-31 | 0.03(0.009) | For HDD Trenchless Engineering | ||

| 13-3/8 | 340 | 14:15 | 2.9 | 13.386(340) | 399-901(1510-3410) | 32-72 | 0.08(0.021) | For HDD Trenchless Engineering | ||

| 13-3/8 | 340 | 14:15 | 3.5 | 13.386(340) | 399-901(1510-3410) | 36-82 | 0.09(0.024) | For HDD Trenchless Engineering | ||