Description

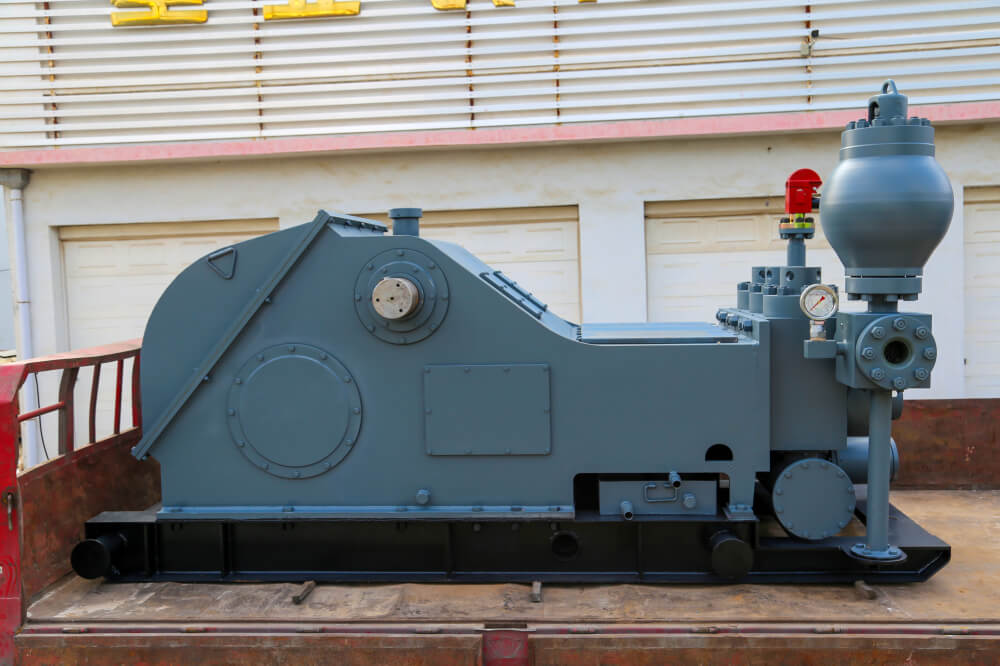

Mud Pump For Sale

Drilling Mud Pump also called Triplex Mud Pump, is an important part of drilling equipment. Drilling Mud Pumps serve as the heart of the mud circulating system. Mud Pump is a machine that sends mud or water to the borehole during the drilling process.

Sino Mechanical Drilling Mud Pump is specifically designed for use in drilling operations to circulate drilling fluid under high pressure down the drill string and back up the annulus.

Working Principle Of Mud Pumps:

During the process of petroleum drilling, mud pumps inject mud into the wellbore as the drill bit advances. Throughout this process, mud pumps cool the drill bit, clean the drilling tools, and transport debris such as rock cuttings back to the surface, facilitating the cleaning of the drilling operation. Petroleum drilling typically employs a positive circulation drilling method, where, under a certain pressure, water, mud, or polymers are conveyed to the bottom of the well through water, high-pressure hoses, and the central hole of the drill rod.

Types Of Mud Pumps:

Based on different driving methods, mud pumps can be categorized into Electric Mud Pumps, Diesel Mud Pumps, Hydraulic Mud Pumps, etc.

Currently, commonly used mud pumps include piston pumps and plunger pumps. Among them, a piston pump, also known as an electric reciprocating pump, operates by the reciprocating motion of the piston, causing a periodic change in the working volume of the pump chamber, leading to the suction and discharge of liquids. Electric Mud Pumps are suitable for high-pressure, low-flow drilling operations. A plunger pump is an essential component of hydraulic systems. Its working principle involves the reciprocating motion of the plunger in the cylinder, causing a change in the working volume of the sealed working chamber to achieve the processes of oil suction and compression. Hydraulic Mud Pumps are suitable for high-pressure, high-flow drilling operations.

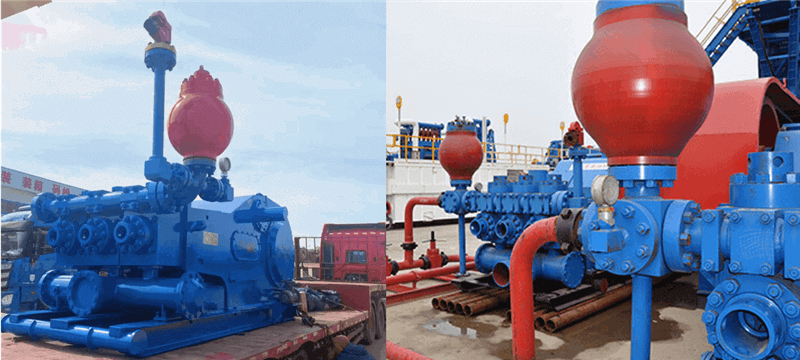

As a global supplier of quality oilfield equipment to the oil and gas industry, Sino Mechanical ships products around the world.We supply the most popular Triplex Mud Pumps and Mud Pump Parts in the industry, which have excellent quality and competitive prices.Our company's full series of Drilling Mud Pumps can withstand the harshest drilling environments and are manufactured in compliance with API standards.

Featuring superior construction and high quality materials, Sino Mud Pumps are built to last. They require minimal maintenance, so your costs stay low so and your drilling operations stay profitable.

Sino Mechanical offers top-quality Drilling Mud Pumps manufactured in accordance with API standards and international specifications. Our Mud Pump selection includes two primary series:China 3NB series Mud Pump and F series Mud Pump.

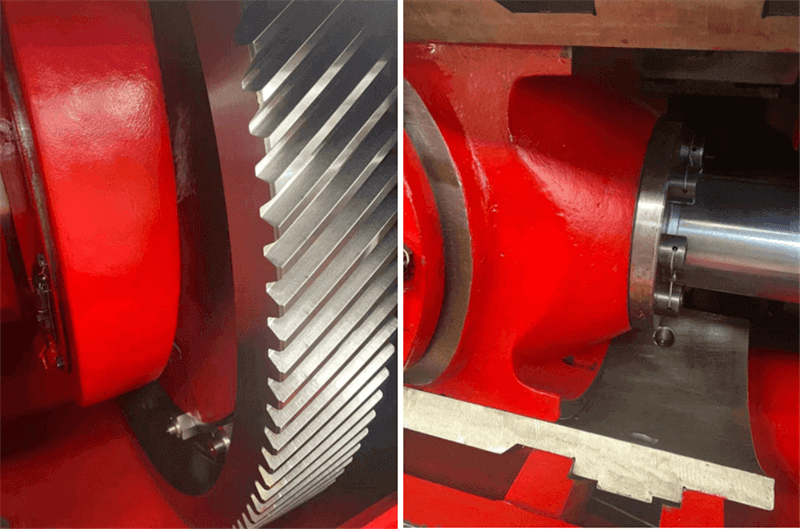

Our onshore mud pumps have a focus on improved pump reliability. They used advanced materials and treatments to improve bearing life, and their carburized and hardened gears resist pitting and wear.

Features of Sino Mechanical F Series Mud Pump:

1.Flexible operation and high work efficiency.

2.Compact size, simple structure, and portability.

3.Smooth operation with low vibration and noise.

4.Strong self-priming ability; can pump liquid without a bottom valve.

5.Pressure discharge remains consistent with varying speed.

6.Adjustable flow rate through a variable speed mechanism.

7.Reversible for changing the liquid flow direction.

8.Complies with API Spec 7K standards.

Features of Sino Mechanical China 3NB Series Mud Pump:

1.Fewer wearing parts and lightweight design.

2.Reduced maintenance time and lower drilling costs.

3.Simplified disassembly for efficient repairs.

4.Minimal displacement fluctuation and high transmission efficiency.

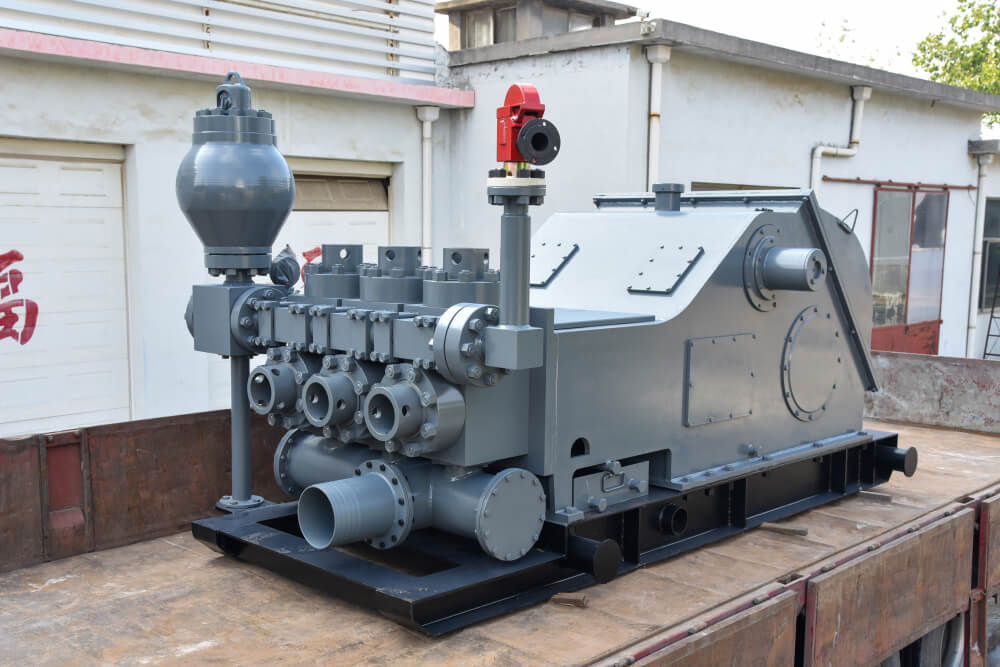

Drilling Mud Pump Parts

Power End: Pinion shaft, crosshead, pony rod/ extension rod / intermediate rod, bearing, crankshaft, connecting rod, gear, etc.

Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

Why Choose Sino Mechanical?

1.Strong Technical Support: We provide detailed technical information tailored to your specific needs.

2.Stable Quality Guarantee: All inspection reports are included with your shipment.

3.Standard & Easy Interchangeability for Spare Parts: Wide options for parts replacement. Parts of F Series and 3NB Series mud pumps can be interchanged with the same specification, following API standards.

4.Quick Response: We are committed to responding to your inquiries within 24 hours.

5.Extensive Project Experience:As a Mud Pump manufacturer,Sino Mechanical has more than 20 years extensive experiences in the performance, application and cost -effective manufacturing of Mud Pump.

6.OEM Services:We design, manufacture, and sell Mud Pump for your drilling applications.

7.Good Quality&Competitive Price:We have a better understanding in Chinese market, with us your money will be safe.we can give you really high quality products with competitive price.

8.After-Sale Service&Quality Control:We have our own experienced QC.We will conduct all necessary tests on the factory equipment and provide certificates, ensuring that we provide you with the best after-sales service.

Sino Mechanical is your trusted partner for comprehensive drilling solutions and high-quality mud pump products and parts.If you want to know latest Mud Pump price,you can contact us by email:sales@sinomechanical.com.

When you buy with Sino Mechanical, you are trading with confidence that your equipment will arrive on time every time.

Specification

Technical Specifications of F series Mud Pump

Model | F500 Mud Pump | F800 Mud Pump | F1000 Mud Pump | F1300 Mud Pump | F1600 Mud Pump |

Type | Triplex Single Acting | Triplex Single Acting | Triplex Single Acting | Triplex Single Acting | Triplex Single |

Rated Power | 500 (373) | 800(596) | 1,000(735) | 1,300(969) | 1,600(1,193) |

Rated Speed (rpm) | 165 | 150 | 140 | 120 | 120 |

Stroke in(mm) | 7-1/2(190) | 9(228.6) | 10(254) | 12(305) | 12(305) |

Max. Liner Dia. in(mm) | 6-3/4(170) | 6-3/4(170) | 6-3/4(170) | 7(180) | 7(180) |

Gear Type | Herringbone | Herringbone | Herringbone | Herringbone | Herringbone |

Valve Pot | API-5﹟ | API-6﹟ | API-6﹟ | API-7﹟ | API-7﹟ |

Gear Ratio | 4.286:1 | 4.185:1 | 4.207:1 | 4.206:1 | 4.206:1 |

Suction Inlet in(mm) | 8(203) | 10(254) | 12(305) | 12(305) | 12(305) |

Discharge Inlet | 4"Flange | 5"Flange | 5"Flange | 5"Flange | 5"Flange |

Lubrication | Forced& | Forced& | Forced& | Forced& | Forced& |

Max. Pressure | 3,945 (27.2) | 5,000(34.5) | 5,000(34.5) | 5,000(34.5) | 5,080(35) |

Overall Size(in) | 144x106x86 | 156x79x66 | 163x89x70 | 174x121x78 | 181x129x106 |

Weight(kg) | 9,770 | 14,500 | 18,790 | 24,572 | 24,791 |

Technical Specifications of China 3NB series Mud Pump

Model | 3NB350 Mud Pump | 3NB500 Mud Pump | 3NB800 Mud Pump | 3NB1000 Mud Pump | 3NB1300 Mud Pump | 3NB1600 Mud Pump |

Power rating HP(kw) | 350(257) | 500(368) | 800(588) | 1000(735) | 1300(955) | 1600(1176) |

Stroke rating SPM | 130 | 120 | 130 | 125 | 120 | 120 |

Stroke length (in/mm) | 180 | 180 | 273 | 273 | 305 | 305 |

Gear ratio | 4.483 | 4.696 | 3.482 | 3.482 | 4.194 | 3.657 |

Inlet dia. (in/mm) | 203 | 203 | 254 | 254 | 305 | 309 |

Outlet dia. (in) | 76 | 83 | 101 | 101 | 101 | 128 |

Valve | 5# | 5# | 6# | 6# | 6# 7# | 7# |

Max. liner diameter (in/mm) | 90-160 | 100-170 | 120-180 | 120-180 | 130-190 | 140-190 |

Overall dimension L*W*H (mm) | 3600*2080*2015 | 3600*2230*2080 | 3900*2155*2052 | 3900*2240*2052 | 4300*2450*2513 | 5500*2822*2660 |

Approx.weight (kg) | 7500 | 8484 | 15700 | 16000 | 20000 | 25560 |