Description

Overview of Deadline Anchor

The deadline anchor is an important part of the weight Indicators, which is suitable for measuring the change of the suspension weight of the drilling tool and the pressure on bit during the drilling or workover of various drilling rigs and workover rigs in petroleum and geological exploration. Help the driller master the working parameters of the drilling rig and workover rig during drilling or workover operations and judge the working status of the drilling tool. The deadline anchor is made of high quality steel and has been tested for 150% overload capacity. High precision, solid, stable and reliable. It is used in conjunction with weight indicators and transducers.

The deadline anchor is a device that converts the dead line tension of the drilling rig into hydraulic pressure.

The deadline anchor is installed on the inside of the derrick or at the corresponding position of the drill floor structure, and is used to fix the dead line end of the large drilling line. In addition, it can also measure the pull force of the dead line and monitor the drilling pressure in real time. It can also play a guiding role when drilling and changing the line. It is a very critical equipment in the drilling hoisting system.

Deadline anchor is used as a display instrument for indicating and recording the drilling string changes in weight and pressure, helping the driller to master the working parameter and judge the drilling state in drilling operation.

Features of Deadline Anchor

1. Can be used in drilling rig, workover rig etc.

2. Material is High strength steel, extended the service time.

3. 1.5 times pressure and tensile test before leaving the factory, high precision, stability, etc.

4. Three forms, horizontal, vertical and draw type.

Deadline Anchor consist of

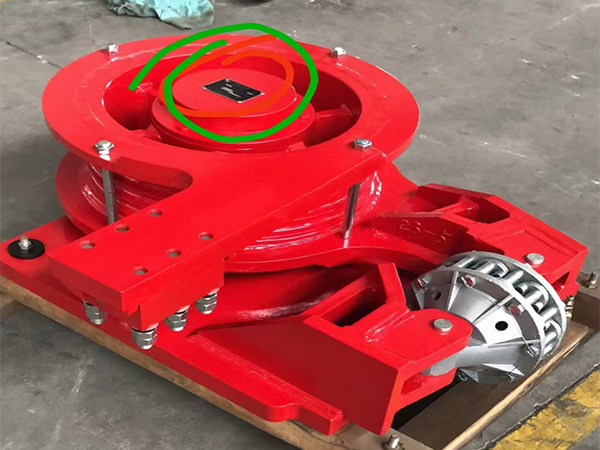

The deadline anchor is mainly composed of two parts: the deadline anchor body and the sensor.

The body of the Deadline Anchor mainly includes parts such as a sheave, a frame, a rope clamp and a pin.

The sensor is a signal conversion tool, which converts the deadline tension signal into a hydraulic signal through the diaphragm.

Applications of Deadline Anchor

The main function of the dead line anchor is to lock the large line and give a pull signal at the locked end.

Installation and Use of Deadline Anchor

1. Bolt the dead-rope retainer securely to the base of the drill rig.

2. The dead rope is completely wound along the sheave groove of the sheave, and then put into the rope clamp to tighten the bolts of the pressing block.

3. Replenish the transformer oil in the sensor in time.

Price of Deadline Anchor

The deadline anchor Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price deadline anchor. If you are looking for deadline anchor or deadline anchor spares, please kindly contact us to get the latest deadline anchor price.

Deadline Anchor Supplier

Sino Mechanical, as a deadline anchor manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of deadline anchor. We are global deadline anchor supplier. We offer a wide range of drilling equipment and have deadline anchor for sale. We also provide OEM services. We design, manufacture, and sell deadline anchor for your drilling applications. If you want to know latest deadline anchor price , don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Deadline Anchor

Deadline Model | Weight indicator Model | Max. Deadline Pulling Force (kN) | Qty of the line | Capacity (kN) | Output pressure sensor (MPa) | |

Vertical | JZG42 | JZ500 | 420 | 12 | 5040 | 6 |

10 | 4200 | |||||

JZG35 | JZ400 | 350 | 12 | 4200 | ||

10 | 3500 | |||||

JZG24 | JZ250 | 340 | 10 | 2880 | ||

8 | 2400 | |||||

JZG20 | JZ200 | 200 | 10 | 2000 | ||

8 | 1600 | |||||

JZG18A | JZ150A | 180 | 10 | 1800 | ||

8 | 1440 | |||||

6 | 1080 | |||||

JZG15A | JZ100A | 150 | 6 | 1200 | ||

4 | 900 | |||||

Horizontal | JZG41 | JZ500A | 410 | 12 | 4920 | 6.83 |

10 | 4100 | |||||

JZG34A | JZ400B | 340 | 12 | 4080 | 6 | |

10 | 3400 | |||||

JZG18 | JZ150 | 180 | 8 | 1440 | ||

6 | 1080 | |||||

JZG15 | JZ100 | 150 | 8 | 1200 | ||

6 | 900 | |||||

JZG10A | JZ40 | 100 | 6 | 600 | ||

4 | 400 | |||||

We can designed as your request. | ||||||